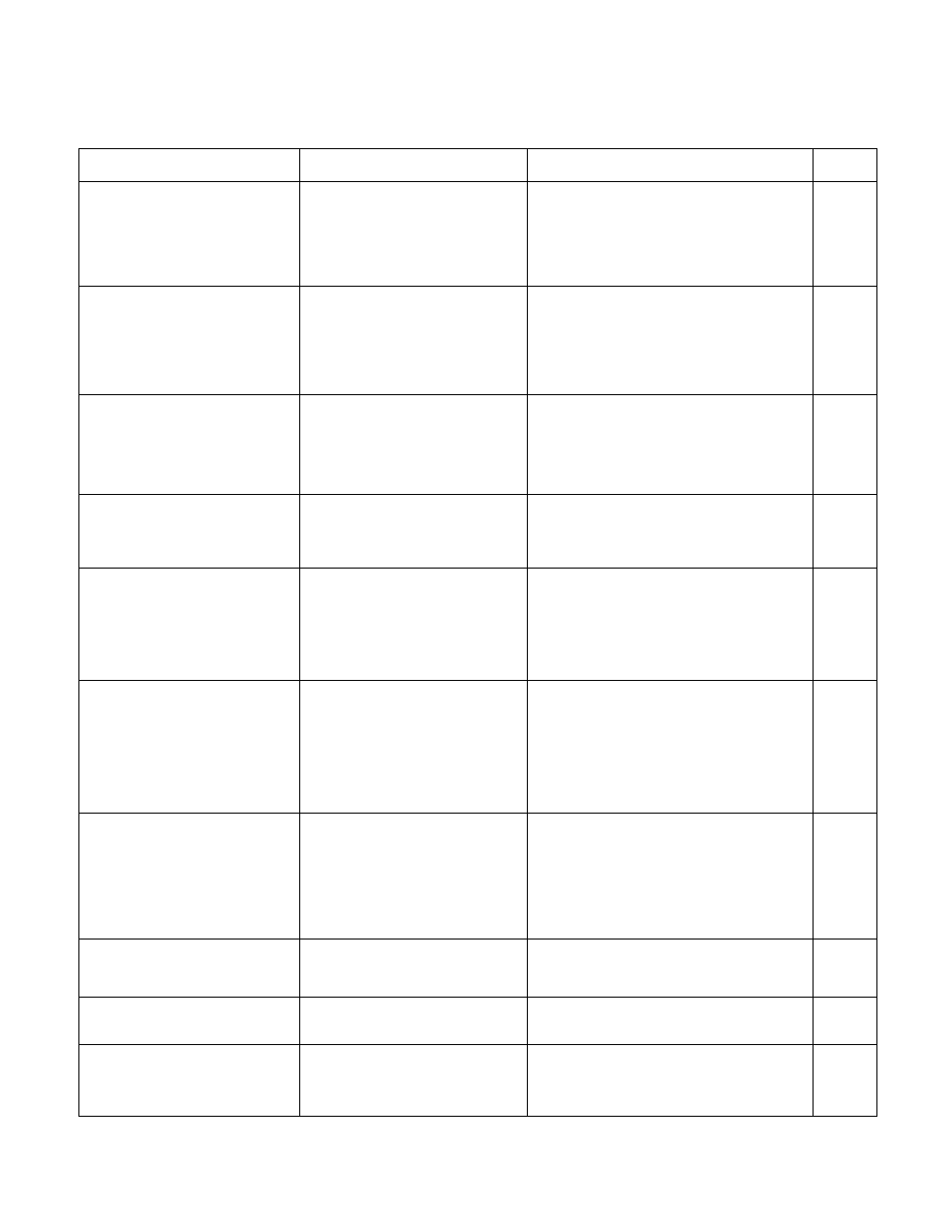

Troubleshooting reference chart, Page 7.1-1 – Generac Power Systems NP-40G User Manual

Page 101

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 7.1- GENERATOR & SPEED CONTROL SYSTEM

Troubleshooting Reference Chart

PROBLEM

POSSIBLE CAUSE

REMEDY

PAGE

1. Engine starts, accelerates,

shuts down at 4500 rpm

a. Carburetor linkage sticking with

throttle stuck open.

B. Stepper Motor failed or seized.

c. Stepper Motor wire connections

broken or disconnected.

d. Stepper Motor not properly

connected.

a. Repair sticking throttle

b. Replace Stepper Motor.

c. Reconnect or repair.

d. Reconnect wires.

3.4-3

3.6- 1

3.6- 1

3.6- 1

2. Overvoltage condition and

speed control system cannot

reduce output voltage.

a. Carburetor linkage sticking with

throttle stuck partly open.

b. Stepper Motor failed or seized.

c. Connection to Stepper Motor Is

broken/dlsconnected with throttle

open.

d. Stepper Motor not properly conn

ected.

a. Repair sticking throttle.

b. Replace Stepper Motor.

c. Repair or replace connections.

d. Reconnect Stepper Motor wires.

3.4-3

3.6- 1

3.6- 1

3.6- 1

3. Engine speed Is maintained

and no-load voltage is good.

However, when load Is applied

output voltage drops and eng

ine shuts down.

a. Carburetor linkage sticking with

throttle partly open.

b. StepiMr Motor failed or seized.

c. Connectlonm to Stepper Motor

Motor broken or disconnected.

d. Stepper Motor not properly

connected.

a. Repair sticking throttle.

b. Replace Stepper Motor.

c. Repair or replace connections.

d. Reconnect Stepper Motor.

3.4-3

3.6- 1

3.6- 1

3.6- 1

4. Engine does not accelerate

when load Is applied. After 10

seconds, engine shuts down.

a. Carburetor linkage sticking

with throttle stuck closed.

b. Stepper Motor failed or seized.

c. Stepper Motor not property

connected.

a. Repair sticking throttle.

b. Replace Stwper Motor.

c. Reconnect Stepper Motor.

3.4-3

3.6- 1

3.6- 1

5. Engine speed and AC output

voltage erratic under constant

load. AC output does not turn

off Intermittently.

a. Stepper Motor failure.

b. Connection to Stepper Motor

broken or disconnected.

c. Stepper Motor not properly

connected.

d. CCQ board failure (erratic de

tection of "zero voltage* cross

ings).

a. Replace Stepper Motor.

b. Repair or replace connections.

c. Reconnect Stepper Motor.

d. Replace CCG Circuit Board.

3.6- 1

3.6- 1

3.6- 1

1.5-4

6. Engine starts but Stepper

Motor does not move. Shut down

occurs after several seconds.

a. Power Supply winding (PS1,

PS2) Is open.

b. Stator Timing winding Is open.

c. Power supply winding In Stator

shorted to ground (See NOTE 1).

d. Timing winding in Stator shorted

to ground.

e. CCQ board does not detect

‘Zero Voltage* crossings.

a. Repair Ir replace bad wlre(s) PS1/PS2

or replace Stator.

b. Repalr/replace bad wlre(s) TIM1/TIM2 or

replace Stator.

c. Replace Stator.

d. Replace Stator.

e. Replace CCG circuit board.

1.5- 2

1.5- 2

1.5- 2

1.5- 2

1.5- 4

7. Engine shuts down but over-

speed above 4500 rpm did not

occur.

e. One of four power windings In

Stator Is open.

b. Main windings shorted to ground.

c. Bad switch In Genistor.

d. No gate connection between CCQ

board and Genistor.

e. No connection between Genistor

and Stator (AC1, AC2, SL1, SL2)

f. CCG board failure.

a. Repalr/replace bad wire(s) AC1/AC2 or

SL1/SL2 or replace Stator.

b. Replace Stator.

c. Replace Genistor.

d. Repalr/replace bad wlre(s) or replace bad

CCG circuit board.

e. Repair or replace connecting wlre(s).

f. Replace CCQ circuit board.

1.5- 1

1.5- 1

1.5- 3

1.5- 4

1.5- 3

1.5- 4

8. AC output turns off Intermittent

ly. Then, engine runs at Idle for 5

seconds. Finally, AC turns back

on and unit runs normally.

a. CCG board failure.

a. Replace CCQ circuit board.

1.5-4

9. Under heavy load, output turns

off and engine speed drops to

Idle.

a. CCQ circuit board failure.

a. Replace CCQ circuit board.

1.5-4

NOTE 1- Shorted power supply win

clings may cause circuit board ground

trace to show evidence of burning.

Page 7.1-1