Ignition module (continued), Ignition coii, Summary of operation – Generac Power Systems NP-40G User Manual

Page 93: Ignition timing, Testing the system, Ignition module (continued) ignition coii, Spark piug

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 6.4- ENGINE IGNITION SYSTEM

Ignition Module (Continued)

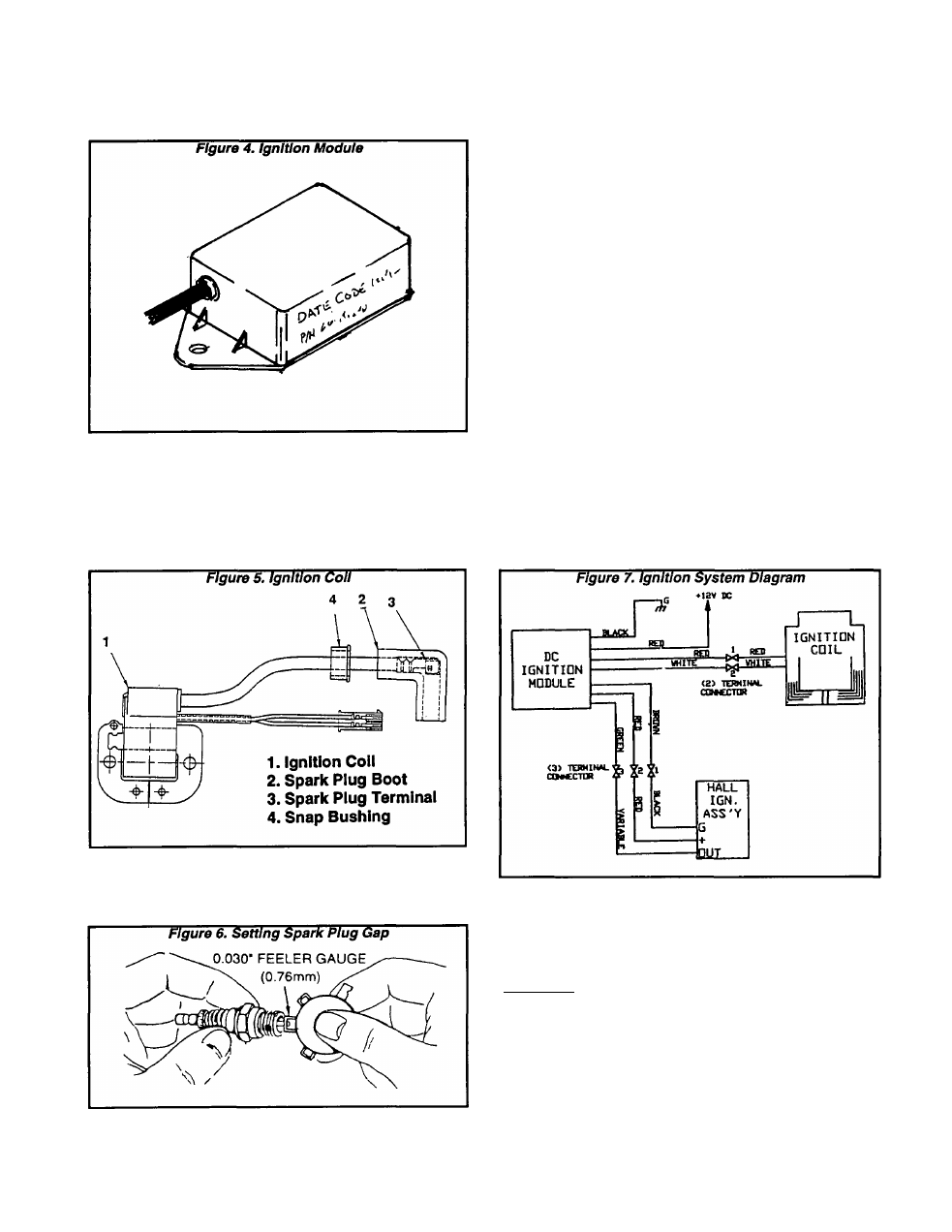

Ignition Coii

Primary Ignition voltage (12 VDC) Is delivered

from the Ignition Module to the Ignition Coll. The

Coil boosts the voltage and delivers the high volt

age to the engine Spark Plug.

Spark Piug

The Spark Plug on GN-190 and GN-220 engines

is a Champion RC12YC (or equivalent).

Clean the Spark Plug and reset its gap to 0.030

inch (0.76mm) every 100 hours of operation. Clean

by scraping or wire brushinq and washing with

commerciaf solvent. DO NOT blast clean the spark

plug.

Summary of Operation

See Figure 6. As the generator’s permanent mag

net rotor turns, magnets in the Rotor hub’s Ignition

Cage rotate past an Ignition Sensor at fixeci inter

vals.

Battery voltage is delivered to an Ignition Module

during cranking and running, via Wire 14. From the

Ignition Module, battery voltag^e is also delivered to

the Ignition Sensor via the RED (+) lead. The Igni

tion Sensor acts as a "trigger" mechanism, causing

the Ignition Module to deliver its output to the

Ignition Coll at timed intervals. Current flows

through the primary coll of the Ignition Coil and

then collapses to Induce a high voltage Into the

Ignition Coil’s secondary coil. This high voltage

(about 25,000 volts) is delivered to the Spark Plug

to fire the spark plug gap.

Components encapsulated in the Ignition Mod

ule provide an automatic spark advance. At crank

ing speeds, ignition will occur at about 15'-18*

BTDC. At higher speeds. Ignition can occur up to

29* BTDC.

Ignition Timing

Ignition timing is fixed and non-adjustable.

Testing the System

GENERAL:

Solid state components Inside the Ignition Sen

sor, Ignition Module and Ignition Coil are not acces

sible and cannot be serviced. If any of these com

ponents is defective, the entire component must

be replaced. The system does not include an arma

ture and there Is no air gap to adjust, or breaker

points to adjust or replace.

Page 6.4-2