Gaseous carburetion, Leakage testing – Generac Power Systems NP-40G User Manual

Page 70

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 4.1- INTRODUCTION TO FUEL SYSTEM

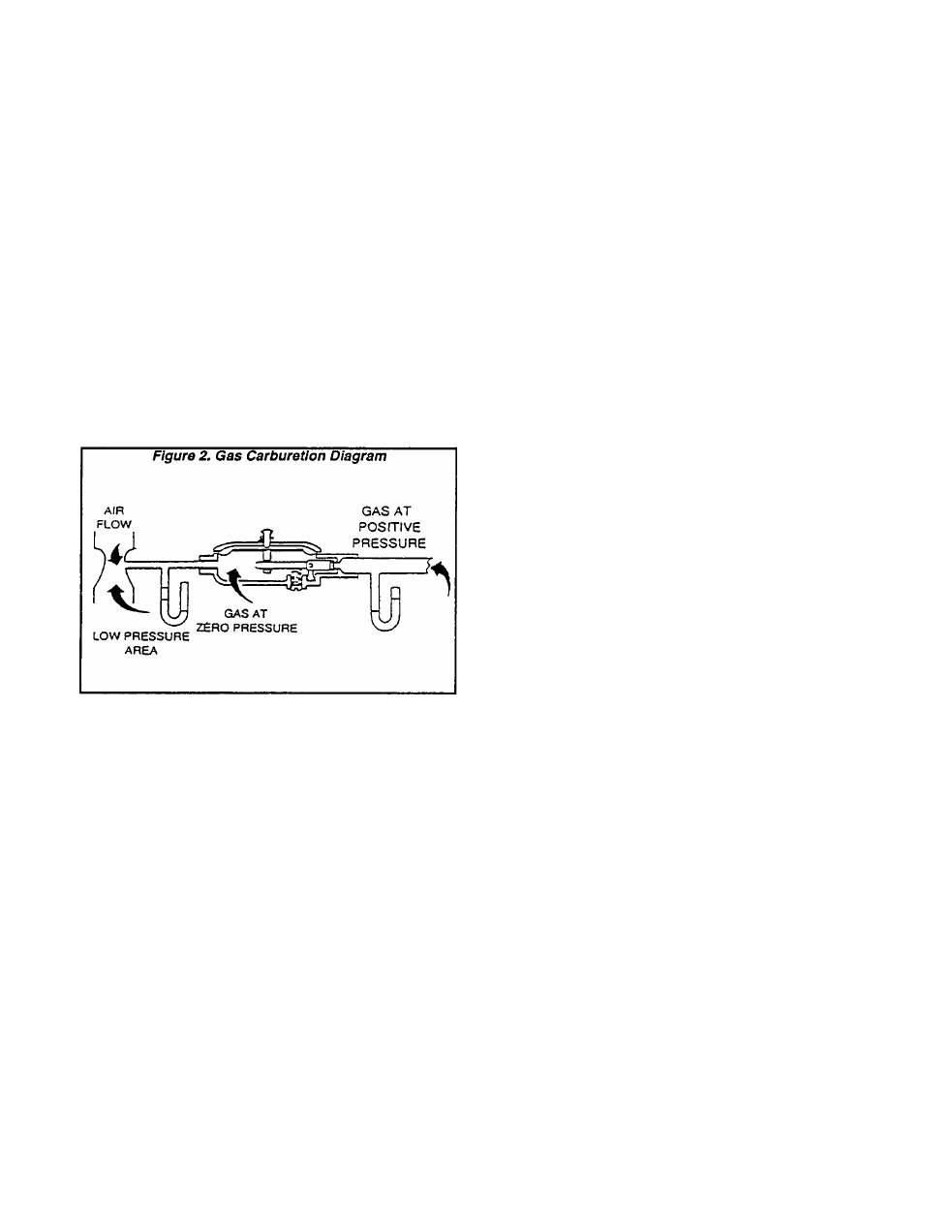

Gaseous Carburetion

Gas at positive pressure is deiivered from the

fuei iockoff soiehoid to the iniet of the reguiator

(about 11-14 inches of water).

As the engine piston moves downward on its

intake stroke, air is drawn into the area above the

piston through the carburetor venturi. A negative

pressure is created at the venturi which is propor-

tionai to the amount of air that is fiowing.

The negative pressure at the carburetor venturi

acts on the reguiator diaphragm to puii the dia

phragm toward the source of iow pressure. A lever,

attached to the diaphragm, opens a metering vaive

which aiiows gas to enter and flow through the

carburetor.

The greater the air flow through the carburetor

venturi, the iower the pressure at the venturi throat.

The lower the pressure at the venturi throat, the

greater the movement of the diaphragm and the

more the metering vaive opens.

The foiiowing requirements of the secondary

reguiator must be emphasized:

□

It must be sensitive to pressure changes In the

carburetor venturi throughout the entire oper

ating range.

n it must positiveiy stop the fiow of gas when the

engine is not running.

□

The slightest air flow through the carburetor

venturi must move the regulator valve off its

seat and permit gas fiow.

Leakage Testing

Whenever any lines, fittings or other compo

nents of the fuel system have been removed and

replaced, the system should be carefully checked

for leaks before It is placed into service.

To check for leakage, start the engine and let It

run. Then use a soap and water solution or an

approved commercial leak detector solution to de

termine if any leakage exists. No leakage is permit

ted.

DANGER!

DO NOT USE FLAME TO CHECK FOR LEAKAGE.

GASEOUS FUEL LINES BETWEEN THE TANK

AND SECONDARY REGULATOR ARE UNDER A

POSITIVE PRESSURE (ABOUT 11 INCHES OF

WATER COLUMN). HOWEVER, GAS PRESSURE

AT THE OUTLET SIDE OF THE SECONDARY

REGULATOR

IS

A

NEGATIVE

PRESSURE

(ABOUT 1 INCH WATER COLUMN). THIS NEGA

TIVE PRESSURE CAN DRAW FLAME INSIDE A

LINE OR FITTING AND CAUSE AN EXPLOSION.

IMPORTANT!

APPLY PIPE SEALANT TO THREADS OF ALL

FITTINGS TO REDUCE THE POSSIBILITY OF

LEAKAGE.

Page 4.1-3