General, Description, Operational check and adjustment – Generac Power Systems NP-40G User Manual

Page 63

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 3,5- AUTOMATIC CHOKE

General

The GN-190 and GN-220 vertical shaft engines

are equipped with an automatic choke. A choke

solenoid is attached to the carburetor choke shaft

by means of a choke control link. Solenoid opera*

tion is controlled by an engine controller circuit

board. The circuit board energizes and de-ener

gizes the solenoid cyclically at a rate dependent on

ambient temperature during engine cranking only.

Description

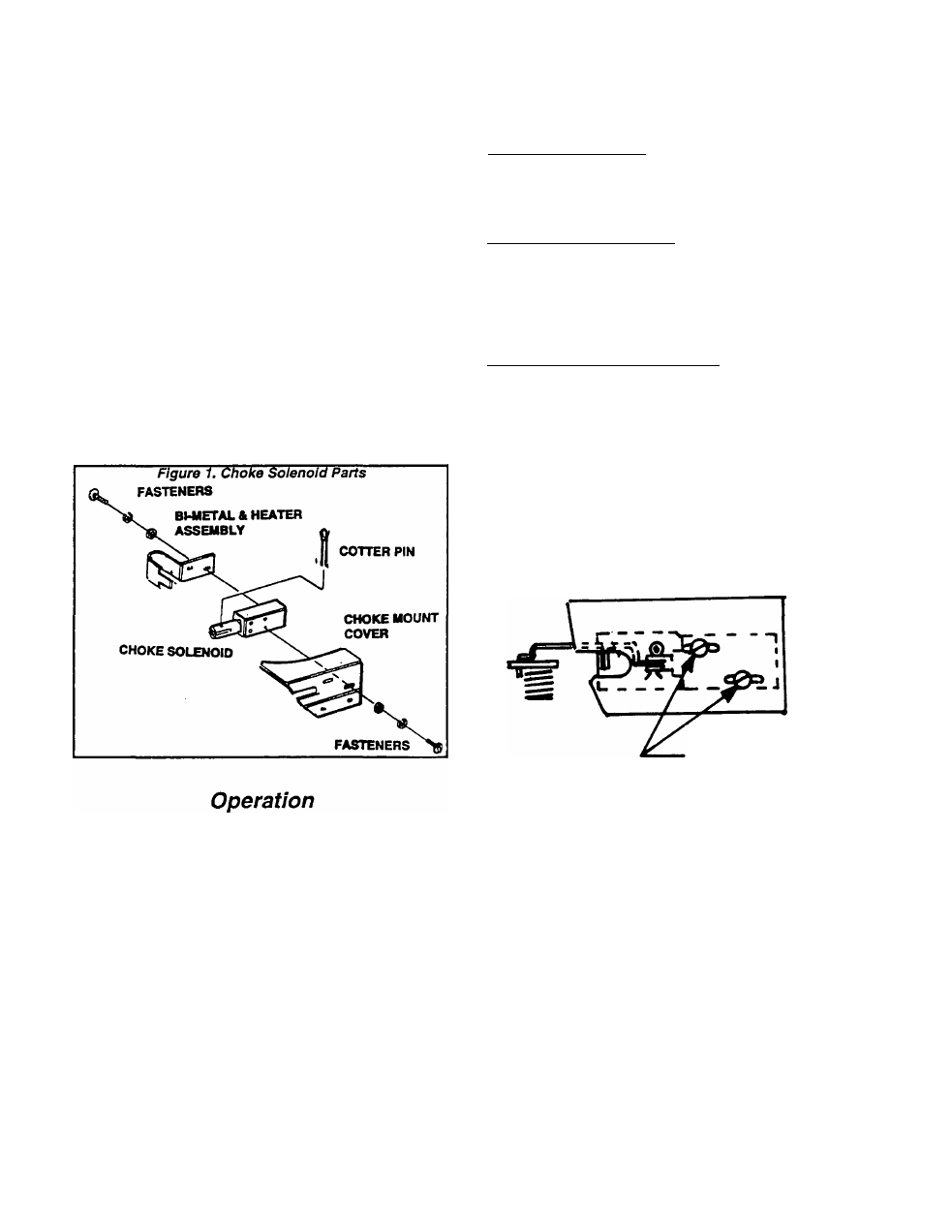

See Figure 1. The CHOKE SOLENOID is retained

to a CHOKE COVER by two No. 4-40 SCREWS,

LOCKWASHERS and FLATWASHERS. The two

screw holes in the COVER are slotted to provide for

axial adjustment of the CHOKE SOLENOID. A COT

TER PIN retains a CHOKE LINK to the SOLENOID.

A CHOKE BI-METAL & HEATER Is retained to the

SOLENOID

by

two

No.

4-40

SCREWS,

LOACKWASHERS and FLATWASHERS.

NOTE: Also see Part 6, "ENGINE ELECTRICAL

SYSTEM". The section on DC control system In

cludes additional Information on choke operation

and the engine controller circuit board.

When the engine Is being cranked, engine con

troller circuit board action energizes the choke

solenoid in regular timed cycles. Each time the

choke solenoid is energized, it closes the carbu

retor choke valve. The circuit board’s choke timer

circuit provides energizes the choke solenoid

(pulls it in) about every 2 to 5 seconds’

When the engine starts, cranking is terminated.

The choke action Is then terminated and the choke

setting is determined by a choke heater (CH).

Operational Check and Adjustment

OPERATIONAL CHECK:

Crank the engine. During cranking, the choke

solenoid should pull in about every 2 to 5 seconds.

If it does NOT pull in, try adjusting the choke.

PRE-CHOKE ADJUSTMENT:

With the solenoid NOT pulled In, the carburetor

choke valve (choke plate) should be about 1/8 inch

from its full open position. If necessary, use needle

nose pliers to bend the tip of the BI-METAL until a

1/8 inch setting is obtained.

CHOKE SOLENOID ADJUSTMENT:

Loosen the two screws that retain the choke

solenoid to Its cover. Adjust axial movement of the

solenoid plunger by sliding the solenoid In the

slotted screw holes of the cover.

Adjust plunger axial movement until (with the

carburetor choke valve closed) the plunger is bot

tomed in the solenoid coil. That Is, until the plunger

is at its full actuated position.

With the choke valve (choke plate) closed and the

plunger bottomed in its coil, tighten the two

screws.

figure 2. Choke Adjustment

Loosen 2 screws and

slide solenoid In the

slots of choke mount

cover. With carburet

or choke plate clos

ed, plunger must

be bottomed In coil.

Page 3.5-1