Test all stator windings to ground (continued), Test for shorts between windings, Results of tests – Generac Power Systems NP-40G User Manual

Page 18: Cleaning the generator

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 1.4- INSULATION RESISTANCE

Test All Stator Windings to

Ground (Continued)

EXAMPLE: Generator rated voltage Is "120 VAC".

Divide

■

...............................................■

obtain

the unit Is "1.12 megohms".

120 by 1000 to obtain "0.12". Add “1" to

"1.12 . Minimum Insulation resistance for

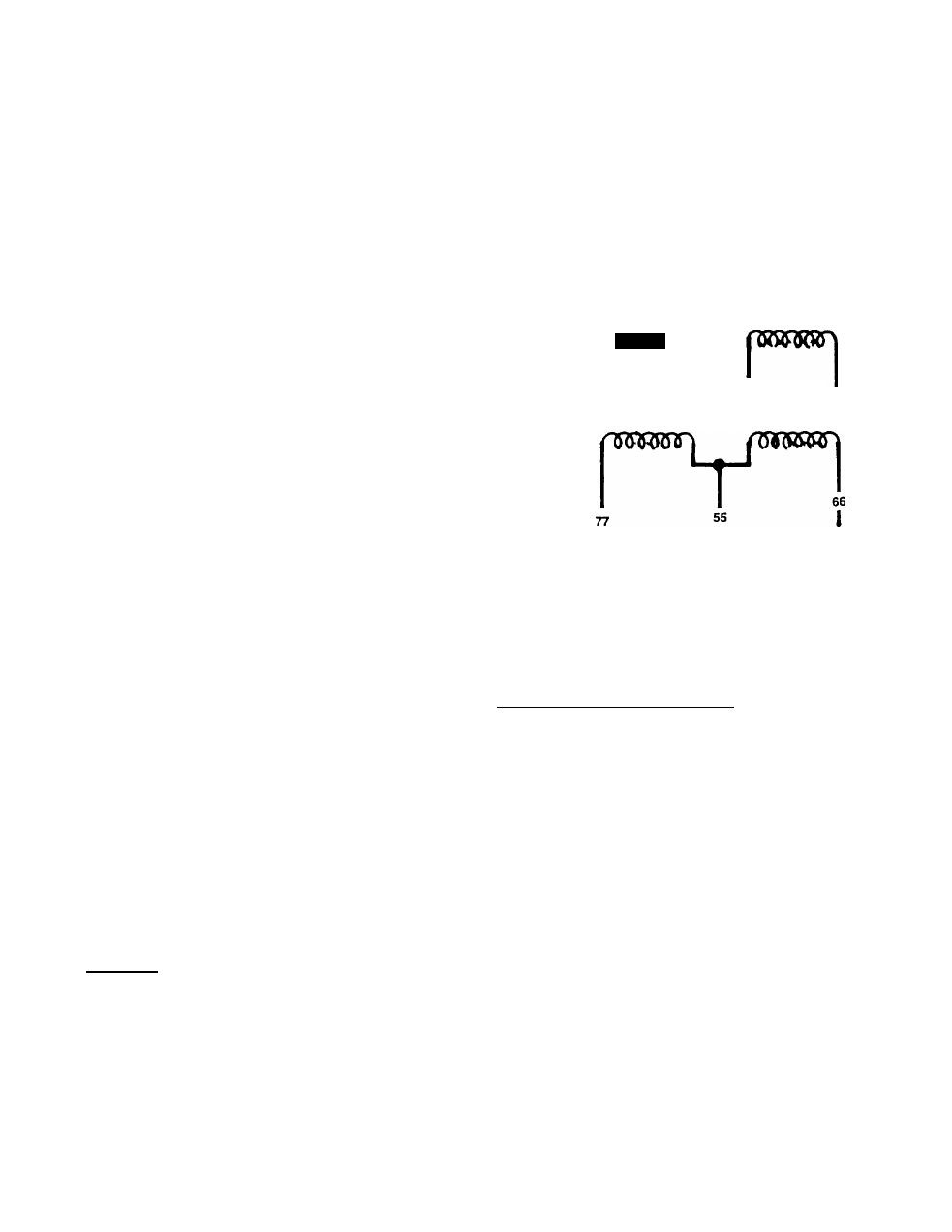

Test for Shorts Between Windings

Figure

2

on the previous page shows the Stator leads

that are brought out of the Stator. Figure 3 is a schematic

representation of the eight (8) Stator windings. To test

for shorts between windings, proceed as follows:

1. Make sure all Stator output leads are isolated from

each other and from the frame.

2. POWER PHASE TO TIMING WINDINGS:- Connect one

tester probe to Stator lead No. 11, the other test probe to

Stator lead TIM1. Apply a voltage of 1000 volts. The

Tester will Indicate a breakdown if the windings are

shorted together.

3. POWER PASE TO POWER SUPPLY WINDINGS: Con

nect one tester probe to Stator lead No. 11, the other

tester probe to Stator lead PS1. Apply 1000 volts. If a

breakdown Is Indicated, the windings are shorted to

gether.

4. POWER PHASE TO BATTERY CHARGE WINDINGS:-

Connect one tester probe to Stator Lead No. 11, the other

probe to Stator lead No. 55. Apply 1000 volts. If break

down Is Indicated, the windings are shorted together.

5. TIMING TO POWER SUPPLY WINDING:- Connect one

tester probe to Stator lead No. TM1, the other test probe

to Stator lead No. PS1. Apply 1000 volts. If breakdown is

Indicated, the windings are shorted together.

6. TIMING TO BATTERY CHARGE WINDING:- Connect

one test probe to Stator lead No. TIM1, the other test

probe to Stator lead No. 55. Apply 1000 volts. If break

down is Indicated the windings are shorted together.

7. POWER SUPPLY TO BATTERY CHARGE WINDING:-

Connect one test probe to Stator lead No. PS1, the other

probe to Stator lead No. 55. Apply 1000 volts. If break

down is indicated, the windings are shorted together.

Results of Tests

1. If testing Indicates that Stator windings are shorted to

ground, the Stator should be cleaned and dried. The

Insulation resistance tests should then be repeated. If,

after cleaning and drying, the Stator again fails the test,

replace the Stator assembly.

2. If testing Indicates that a short between windings

exists, clean and dry the Stator. Then, repeat the tests. If

Stator fails a second test (after cleaning and drying),

replace the Stator assembly.

Cleaning the Generator

GENERAL:

If testing indicates that the insulation resistance is

below a safe value, the winding should be cleaned.

Proper cleaning can be accomplished only while the

generator is disassembled. The cleaning method used

should be determined by the type of dirt to be removed.

Be sure to dry the unit after it has been cleaned. An

electric motor repair shop may be able to assist with

cleaning. Such shops are often experienced in special

problems (sea coast, marine, wetland applications, etc.).

Figure 3. Schematic- Stator Windings

POWER

PHASE 1

pravm ппушт|

AC1

I

AC2

h

PHASE 2

POWER

^

SL1

à

11

SL2

h

f

POWER

SUPPLY

PS1

PS2

.

О

^

О

TIMING

TIMI

T1M2

BATTERY

CHARGE

USING SOLVENTS FOR CLEANING:

A solvent is generally required when dirt contains oil

or grease. Only petroleum distillates should be used to

clean electrical components. Recommended are safety

type petroleum solvents having a flash point greater than

100’ F. (38* C.).

Use a soft brush or cloth to apply the solvent. Use care

to avoid damaging magnet wire or winding Insulation.

After cleaning, dry all components thoroughly with mois

ture-free, low pressure compressed air.

DANGER!

DO NOT WORK WITH SOLVENTS IN ANY EN

CLOSED AREA. ALWAYS PROVIDE ADEQUATE

VENTILATION. FIRE, EXPLOSION OR OTHER

HEALTH HAZARDS MAY EXIST UNLESS ADE

QUATE VENTILATION IS PROVIDED. WEAR EYE

PROTECTION. WEAR RUBBER GLOVES TO PRO

TECT THE HANDS.

CAUTIONI

Some generators use epoxy or polyester base

winding varnishes. Use solvents that do not at

tack such materials.

Page 1.4-2