O_1013, O_1022, O_1029 – BUCHI DuMaster D-480 User Manual

Page 44: O_1014, O_1023, O_1030, O_1016, O_1024, O_1031, O_1017

Operation Manual D-480

©BÜCH Labortechnik AG

4 - Understanding the instrument and planning its use

44

I

Mechanical sample insertion and O

2

dosing system

II

Furnace area and reaction zone

III

Gas drying

IV

Detector

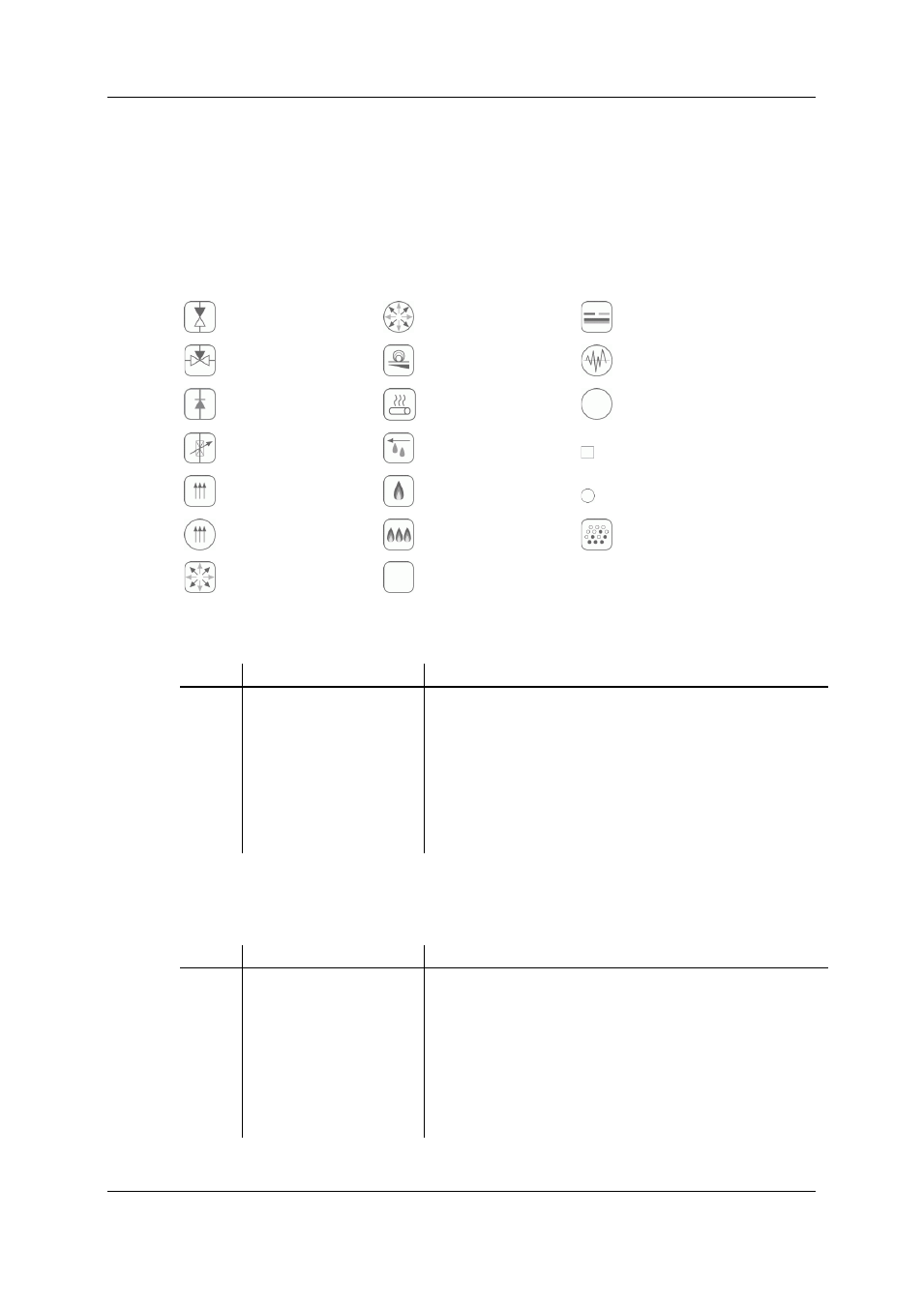

Symbols

The following list names the functional and basic symbols:

Two-way valve

Pressure sensor

Gas separation

Three-way valve

Loop

Measuring cell

Check valve

Heated tube

Sensor

Throttle

Drying

Hose line

Flow controller

Combustion

Copper tube

Flow sensor

Post combustion

Reduction

Pressure contoller

Actuator

Mechanical sample insertion and O

2

dosing system (I)

The following table describes the components of the unit and their functions:

Part

Name

Function

1

Carousel

holds all samples in a series.

transports the current sample into the ball valve

2

Ball valve with Ni flap

allows the metered addition of O

2

during the combustion.

holds the current sample.

shuts the current sample off from the ambient air and

allows the system to displace any ambient air with a

CO

2

/O

2

gas mixture.

transports the current sample into the combustion tube.

For details on sample insertion, cf. Sample insertion and initiation of measurement (on page 47).

Furnace area and reaction zone (II)

The following table describes the components of the unit and their functions:

Part

Name

Function

3

Furnace

holds the combustion tube, reduction tube and post

combustion tube at a constant temperature and thereby

ensures reproducible analysis results.

4

Combustion tube with tube

filling

Space for complete combustion of the sample including

combustion catalyst.

Binds disturbing alkali and earth alkali elements.

5

Ash crucible

Holds combustion residues and sample packing of

analyzed samples; for fast, easy emptying without

replacing the combustion tube.