Rockwell Automation FlexPak/WebPak 3000 DC Drive AutoMax Network Communication Board User Manual

Page 83

W

ebPak

3000 Drives

: Regist

er

M

a

p

7-

15

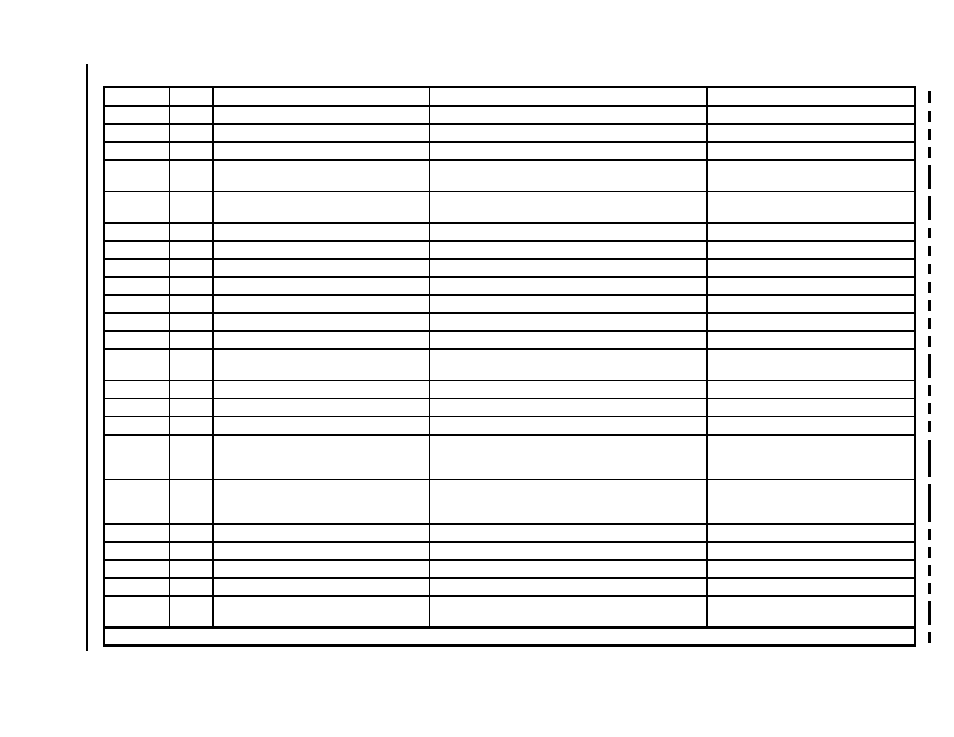

Table 7.11 – WebPak 3000 Register Map, Drop_3: Master Read Registers, FULL Connection. Runtime Signal Data (Drive Output Data)

Register

Bit

Parameter Name (Number)

Description

Settings

0

J

11

ANLG

TACH

VLT

SCL

(P.792)

Position to set J11 jumper

16; 31; 62; 126; 250

1

J

14

ANLG

TACH

VLT

RNG

(P.793)

Position to set J14 jumper

LOW

;

HIGH

2

J

15

REGULATOR

TYPE

(P.799)

Indicates position of jumper J15

SPEED

/

VOLTAGE

;

CURRENT

/

TORQUE

3

J

18

ARM

I

FB

RESISTOR

(P.395)

Indicates the burden resistor position

1 (15 ohm); 2 (20 ohm) 3 (30 ohm); 4 (39

ohm)

4

JOG

RAMP

OUTPUT

(P.294)

Jog ramp reference value immediately after the jog ramp

function

5

LEVEL

DETECT

1

OUTPUT

(P.648)

Output of level detector 1

ON

,

OFF

6

LEVEL

DETECT

2

OUTPUT

(P.649)

Output of level detector 2

ON

OFF

7

LOSSES

COMPENSATION

(P.316)

Output of the losses compensation calculator

8

NETW

COMM

STATUS

(P.908)

Status of network communication

NOT

ACTIVE

,

ACTIVE

9

NETW

TYPE

&

VERSION

(P.909)

Type of network board installed and its software version

10

POS

LL

RATIO

OUT

(P.247)

Value of the position loop lead/lag ratio

11

POS

LL

WLO

OUT

(P.246)

Value of the position loop lead/lag low frequency

12

POS

LOOP

ERROR

(P.254)

Position loop error signal (difference between

POSITION

REFERENCE

(P.240) and position feedback)

13

POS

PI

KP

OUT

(P.248)

Value of the position loop

PI

proportional gain

14

POS

PI

WLD

OUT

(P.249)

Value of the position loop

PI

lead frequency

15

POS

RAMP

OUTPUT

(P.237)

Output of the position major loop ramp block

16

ROLL

DIAMETER

(P.865)

Value of the calculated roll diameter in same units used

for

EMPTY

CORE

DIAMETER

(P.830) and

FULL

ROLL

DIAMETER

(P.125)

17

SPD

SOURCE

SELECT

OUT

(P.193)

Selected speed reference source used as input to the

speed reference ramp section (rpm or user-defined

units)

18

SPEED

CROSS

OVER

(P.133)

Speed loop cross over frequency

19

SPEED

LAG

FREQ

OUT

(P.252)

Value of the speed loop lag frequency

20

SPEED

PI

KP

OUT

(P.251)

Value of the speed loop

PI

proportional gain

21

SPEED

PI

WLD

OUT

(P.250)

Value of the speed loop

PI

low freuqncy

22

SPEED

RAMP

INPUT

TP

(P.198)

Value of the speed reference signal immediately before

the speed loop

S

-

CURVE

block

Runtime signal data are updated by the regulator every 10 msec.