Rockwell Automation FlexPak/WebPak 3000 DC Drive AutoMax Network Communication Board User Manual

Page 58

6-

10

Aut

o

Max

Net

w

or

k Comm

unicat

ion

O

p

tion

B

oard

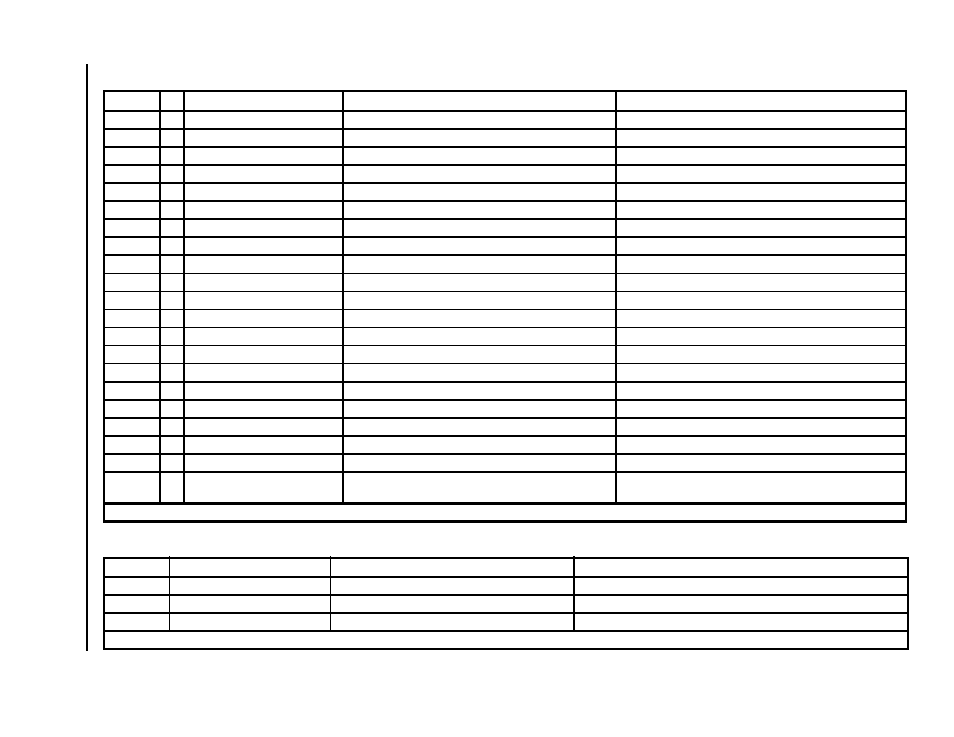

Table 6.6 – FlexPak 3000 Alternate Register Map, Drop_1: Master Write Registers, BASIC and FULL Connections. Tunable Data (Drive Input Data)

Register Bit Parameter Name (Number)

Description

Settings

40

ACCELERATION

TIME

(P.001)

Min. time to accelerate from zero to

TOP

SPEED

(P.011)

seconds * 10

41

DECELERATION

TIME

(P.002)

Min. time to decelerate from

TOP

SPEED

(P.011) to zero

seconds * 10

42

MINIMUM

SPEED

(P.003)

Lowest operating speed

RPM

43

MAXIMUM

SPEED

(P.004)

Highest operating speed

RPM

44

POSITIVE

CURRENT

LIM

(P.005)

Highest amount of current for the forward bridge

% of

MOTOR

RATED

ARM

AMPS

(P.008)

45

NEGATIVE

CURRENT

LIM

(P.006)

Highest amount of current for reverse bridge

% of

MOTOR

RATED

ARM

AMPS

(P.008)

46

S

-

CURVE

ROUNDING

(P.014)

Smoothing of the speed/voltage loop reference

%

47

TRIM

RANGE

(P.109)

Amount the trim reference will affect the drive reference %

48

SPD

LOOP

PI

PROP

GAIN

(P.211)

Speed loop

PI

proportional gain

gain * 100

49

SPD

LOOP

PI

LEAD

FREQ

(P.212)

Speed loop

PI

block lead break frequency

radians/second * 100

50

CML

PI

PROP

GAIN

(P.301)

CML

PI

proportional gain

gain * 1000

51

CML

PI

LEAD

FREQUENCY

(P.302)

CML

PI

lead break frequency

radians/second

52

OCL

PI

PROP

GAIN

(P.808)

OCL

PI

block proportional gain

gain * 100

53

OCL

PI

LEAD

FREQ

(P.809)

Outer control loop

PI

block lead break frequency

radians/second * 100

54

OCL

PI

POSITIVE

LIMIT

(P.810)

OCL

PI

block positive limit

%

55

OCL

PI

NEGATIVE

LIMIT

(P.811)

Outer control loop

PI

block negative limit

%

56

CURRENT

COMPOUNDING

(P.209)

Sets the level of current compounding

%

57

NORMALIZED

INERTIA

(P.222)

Combined inertia of motor and load

seconds * 100

58

NETW

OUT

REG

1

SELECT

(P.902) Number of the parameter readable in Drop_1, register 7 If no valid parameter selected, set to 0=motor speed in

RPM

59

NETW

OUT

REG

2

SELECT

(P.903) Number of the parameter readable in Drop_1, register 8 If no valid parameter selected, set to 0=armature voltage (volts)

60

NETW

OUT

REG

3

SELECT

(P.904) Number of the parameter readable in Drop_1, register 9 If no valid parameter selected, set to 0=armature current in

amps*10 or amps

Tunable data are read by the regulator approximately every 600 msec when Tune/Config Input Enable bit = 1.

Table 6.7 – FlexPak 3000 Alternate Register Map, Drop_1: Master Write Registers, BASIC and FULL Connections. Configurable Data (Drive Input Data)

Register

Parameter Name (Number)

Description

Settings

61

FEEDBACK

SELECT

(P.200)

Type of speed/voltage loop feedback

0=

ARMATURE

VOLT

; 1=

DC

TACH

; 2=

PULSE

TACH

; 3=

AC

TACH

62

NETW

CONNECT

TYPE

(P.910)

AutoMax network connection type

0=

BASIC

; 1=

FULL

63

AMX

NETW

REF

SELECT

(P.911)

AutoMax network reference selection

0=

DIRECT

; n=

BROADCAST

n (n=1 to 8)

Configurable data are read by the regulator approximately every 600 msec when Tune/Config Input Enable bit=1 and the drive is not running or jogging.