Rockwell Automation FactoryTalk Metrics User Guide User Manual

Page 70

Chapter 3 Collecting Performance Data

negatively affected by time periods that are scheduled as

unavailable (e.g., weekends, evenings).

Click one the available buttons to access the respective editors

that you can use to create or modify composites, exceptions, or

time patterns:

• Click Composite to assign time patterns and exceptions to

activity areas.

• Click Exception to define availability exceptions and apply

them to appropriate activity areas.

• Click Pattern to define repeating time patterns of available

time, unavailable time, and shifts.

If a site changes shift schedules frequently, the Collect

Scheduled Availability information from the control

system option is more flexible than using a time pattern.

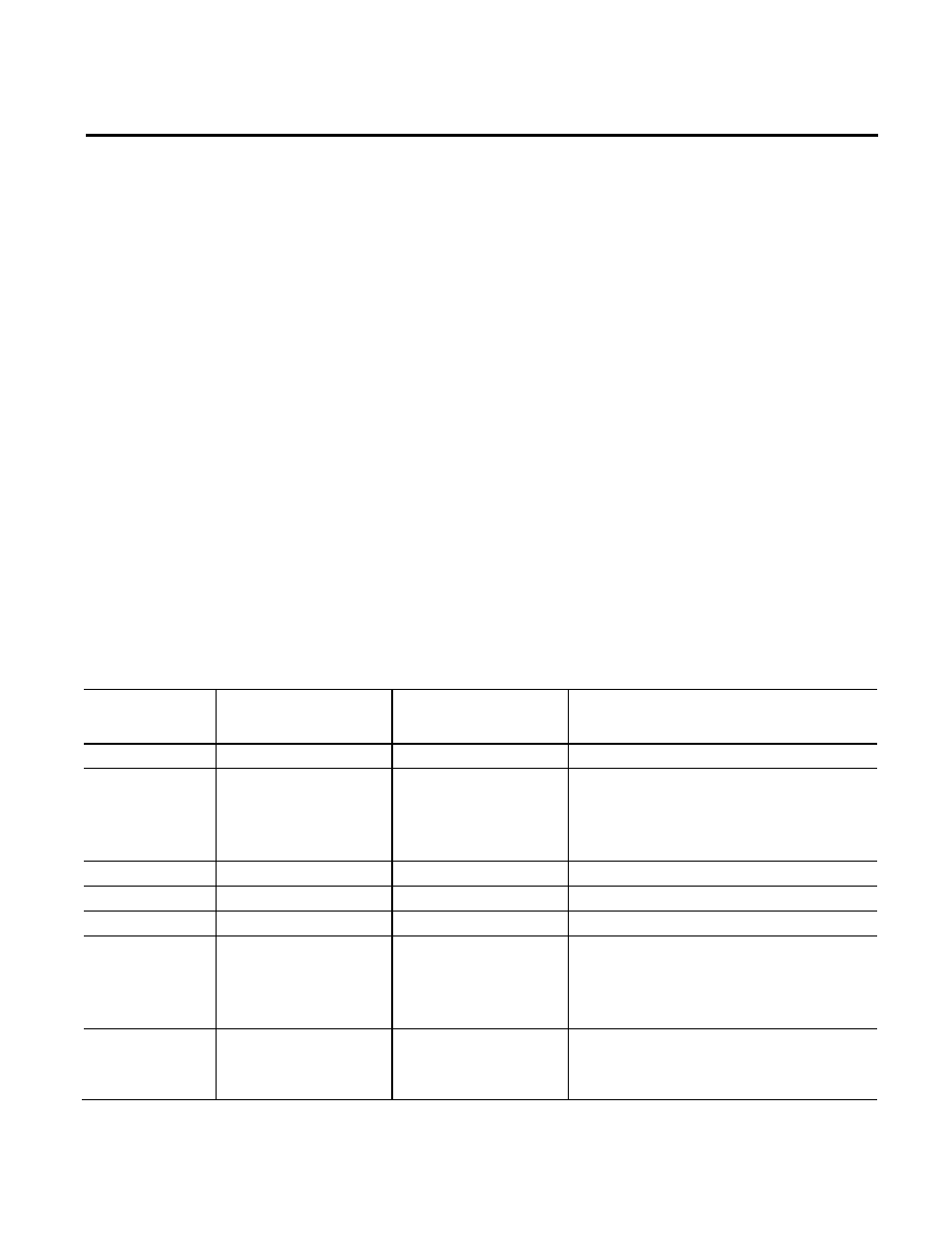

The following table illustrates how data collection will behave for

different configurations of Shift Id and Scheduled Availability.

Shift Data Point

Value

Scheduled Available

Data Point Value

Scheduled Availability

Accumulating

Shift information that is written to the

database

Value > 0

Not Selected

Yes

> 0 value with description.

Value is 0

Not Selected

No

If previous shift value > 0 then -1 * previous Shift

value.

Otherwise, -1 for shift number with no shift

description.

Value < 0

Not Selected

No

< 0 value for shift number with no shift description.

Value > 0

Value is not 0

Yes

> 0 value with description.

Value > 0

Value is 0

No

> 0 value with description.

Value is 0

Value is not 0

Yes

If previous shift value > 0 then -1 * previous Shift

value.

Otherwise, -1 for shift number with no shift

description

Value is 0

Value is 0

No

If previous shift value > 0 then -1 * previous Shift

value.

Otherwise, -1 for shift number with no shift

70

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014