Rockwell Automation FactoryTalk Metrics User Guide User Manual

Page 45

Collecting Performance Data Chapter 3

The Ideal Cycle Time parameter is part of the Throughput value in

the OEE equation. It indicates the time, in seconds, which the

activity area should take to produce a single good part. It can have a

decimal value. If the activity area produces parts faster than the ideal

cycle time, the OEE rating will improve. If the activity area produces

parts slower than the ideal cycle time, the OEE rating will

deteriorate.

To configure the Ideal Cycle Time:

Under Ideal Cycle Time, in the Cycle Time Type list, select one of

the following options:

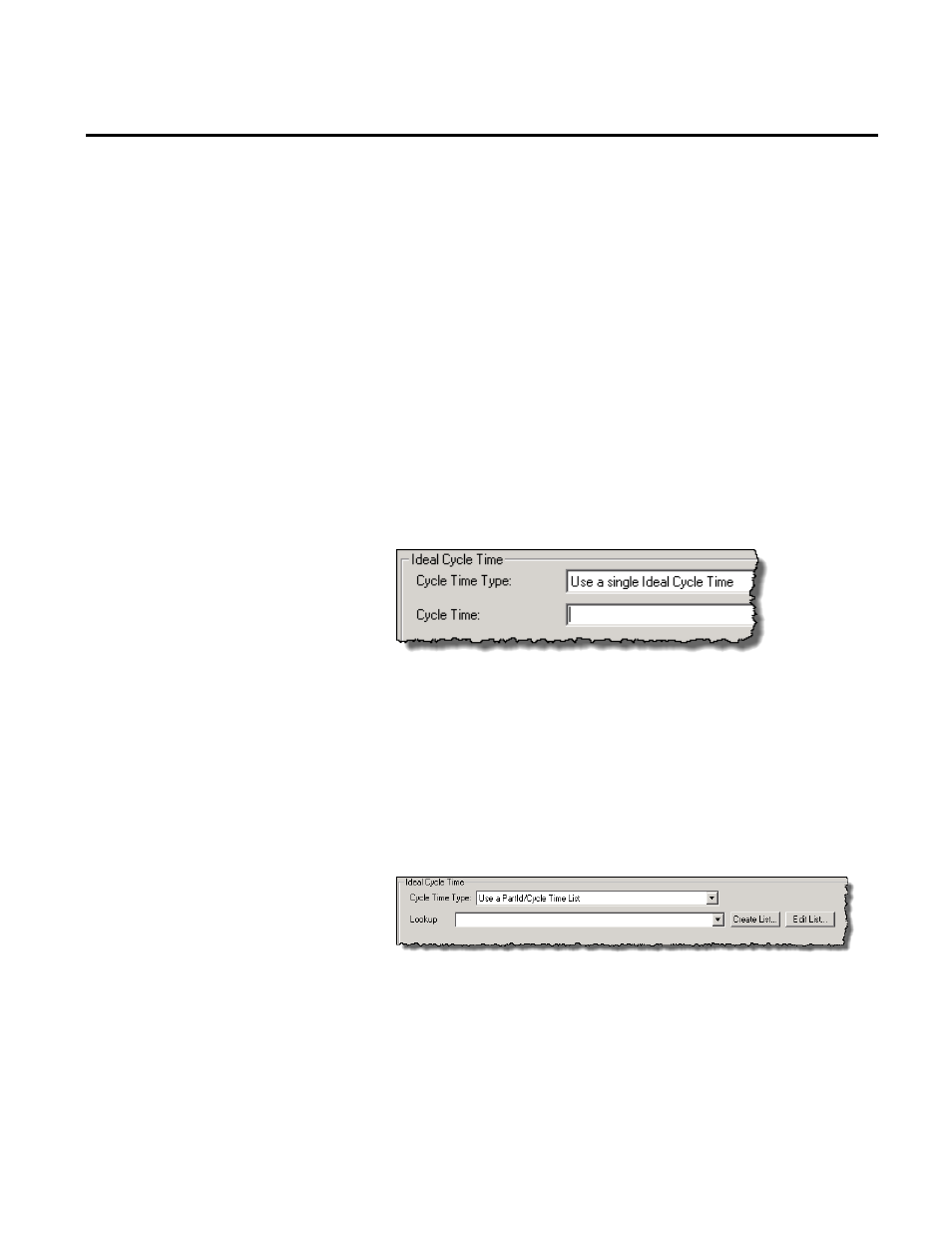

• Use a single Ideal Cycle Time

Select this option if the activity area always takes the same

amount of time to produce each part, regardless of what type

of part is being produced. Parts that take longer than the

specified cycle time will negatively impact the OEE rating.

In the Cycle Time box, specify the part production time in

seconds.

• Use a PartId/Cycle Time List

Select this option if you want to improve the accuracy of the

OEE rating. With this option, the application uses the

specified lookup list to find the Ideal Cycle Time for the type

of part that is being produced. This assumes that the activity

area always takes the same amount of time to produce a certain

type of part.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

45