Rockwell Automation FactoryTalk Metrics User Guide User Manual

Page 141

Automated Configuration Chapter 4

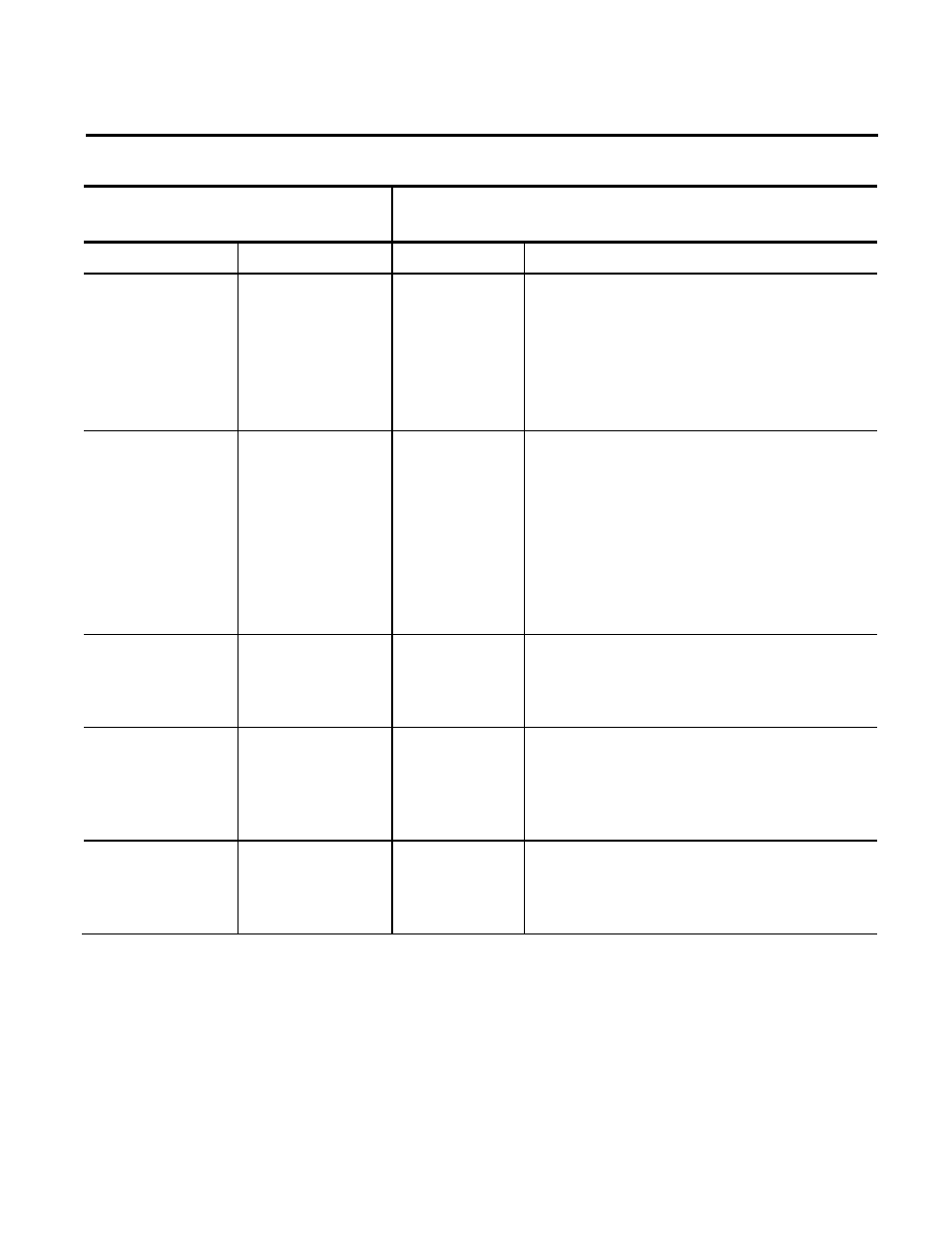

These items of the UDT workcell template: Are mapped to these performance parameters in FactoryTalk

Metrics:

Item

Data type

Item

Description

TotalParts

INT

Total Part Count

The value is not taken from the controller, but calculated by

FactoryTalk Metrics as:

Good Parts + Scrap Parts = Total Parts

If you need the Total Parts value to be collected from the

controller, you must configure it manually in the

Configuration Console after you run the FactoryTalk Metrics

Configuration Tool.

Shift

INT

Scheduled

Availability - Shift

By default, the FactoryTalk Metrics Configuration Tool

configures Scheduled Availability to be collected from the

controller. The UDT Shift tag is expected to contain a

number that corresponds to the workcell’s current shift

number. If the Shift value is greater than zero, the workcell

is assumed to be on shift and available to run.

Tip: You can create a list to convert numeric values returned

by this tag into string values. See "Configuring Scheduled

Availability (page 65)" for details.

Running

BOOL

Running State

Determines whether or not a workcell is running. It is an

important component of several KPI calculations.

If the Running tag value is

true

(or

high

), the workcell is

considered to be running.

Monitored_Availability BOOL

Monitored

Availability

A real-time override of Scheduled Availability. It is

commonly used to prevent Available Time from

accumulating, if the workcell is scheduled to be available

but cannot produce anything due to some factor that is

beyond its control.

Monitored_Value

INT

Custom Events,

monitored value

type

Contains a machine state code.

Tip: You can create a list to convert numeric values returned

by this tag into string values. See "Configuring Scheduled

Availability (page 65)" for details.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

141