Rockwell Automation FactoryTalk Metrics User Guide User Manual

Page 140

Chapter 4 Automated Configuration

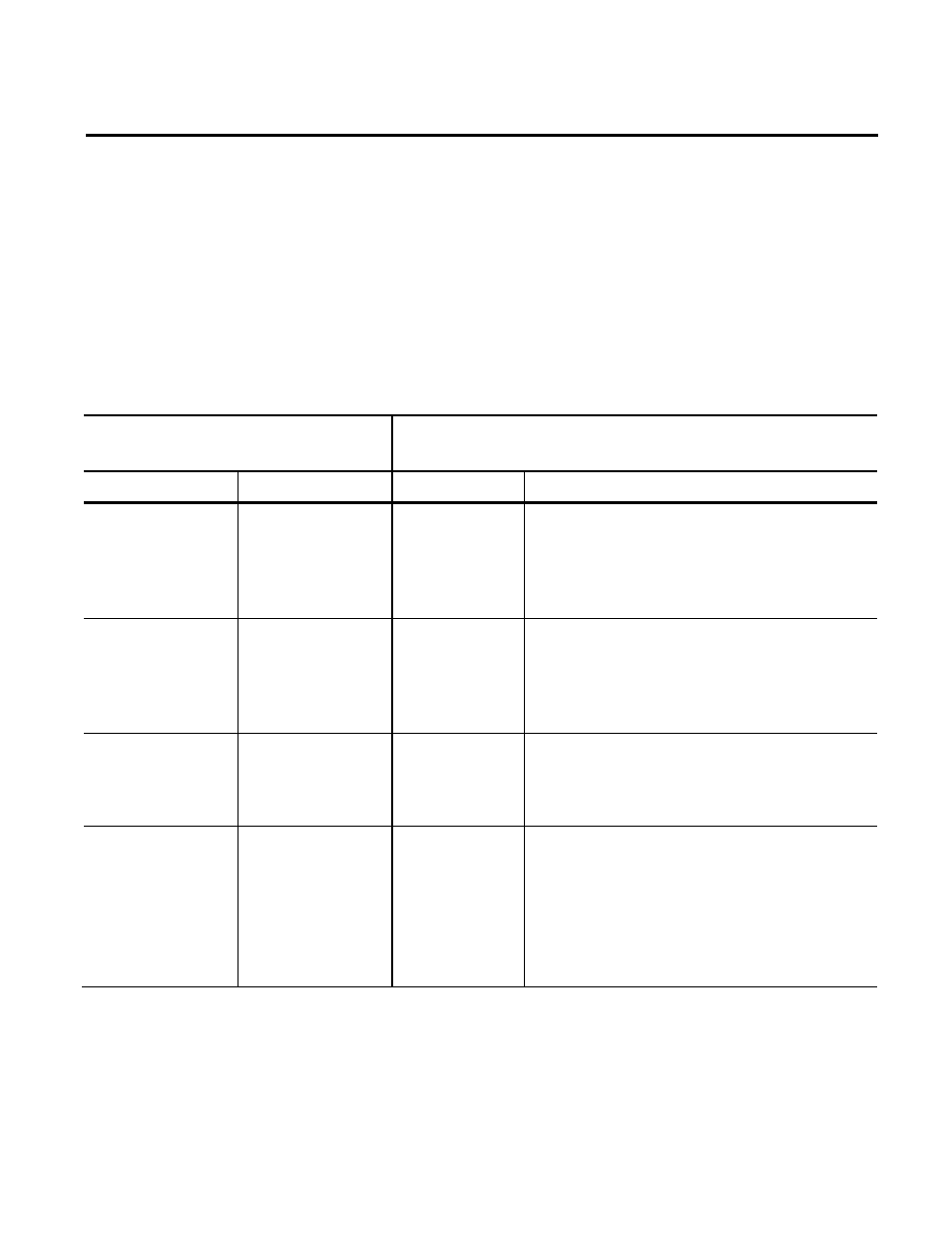

The following table lists the UDT tags from a ControlLogix

controller and their corresponding performance parameters in

FactoryTalk Metrics. You may need to modify the UDT tags in the

controller to ensure that they contain valid data for FactoryTalk

Metrics to collect.

All the items listed in the table are unscheduled, unless otherwise

stated.

These items of the UDT workcell template: Are mapped to these performance parameters in FactoryTalk

Metrics:

Item

Data type

Item

Description

PartId

STRING

Part Id

Identifies the product being produced at the workcell.

Its value changes when the workcell produces a different

part. You must coordinate this value with the part count

values by associating the part counts with the correct Part

Id.

IdealCT

REAL

Ideal Cycle Time

The time required for one part to pass through the workcell

under ideal conditions. It is a real value, represented in

seconds.

Usually, the Ideal Cycle Time value changes only if the Part

Id changes.

GoodParts

INT

Good Part Count

The number of the first quality parts produced by the

workcell.

It acts like an accumulator and increases in value. The value

never decreases unless it is reset.

ScrapParts

INT

Scrap Part Count

The number of parts produced by a workcell that cannot be

categorized as Good Parts.

From the machine-efficiency perspective, the parts have no

value, and the cycle time taken to produce them at the

current workcell has been wasted.

It acts like an accumulator and increases in value. The value

never decreases unless it is reset.

UDT Tags and FactoryTalk

Metrics Performance

Parameters

140

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014