Overview of procedures – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 64

Overview of Remaining

Configuration Procedures

Chapter 4

4-3

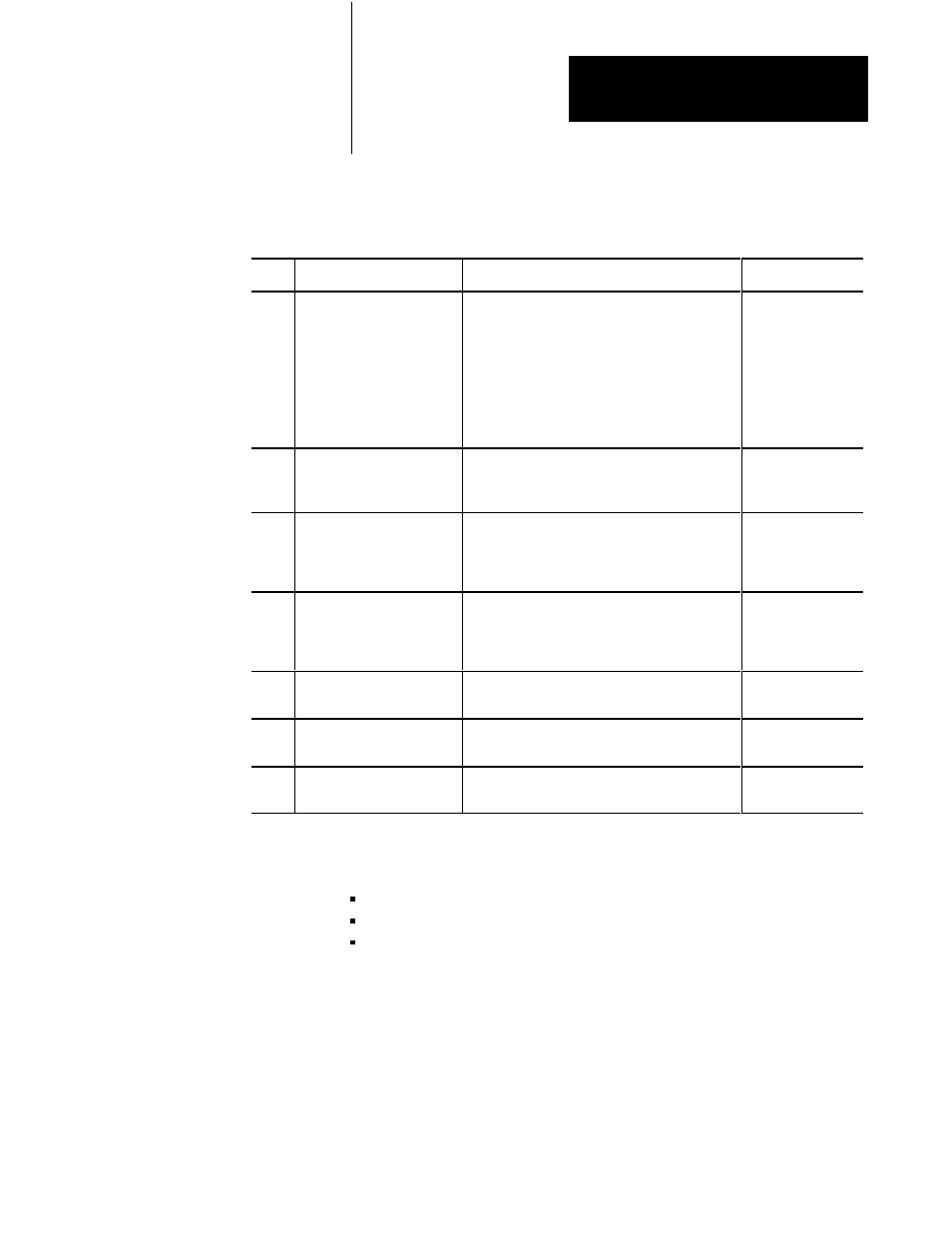

Configuration procedures described in the next several chapters are

outlined below. They are sequential in nature: configuration information

determined in initial chapters is needed in later chapters.

Step: Procedure:

Description:

Refer to:

1

Jog Your Machine

You enter machine jog pressure and flow setpoints

into the Jog Configuration (JGC) block.

You jog your ram (screw), clamp, and ejector

with commands in the DYC block to further refine

your jog configuration.

You enter jog pressure alarm setpoints into the JGC

block.

Chapter 5

2

Select Command and Status

Bits to Sequence Machine

Operation

You write PLCĆ5 ladder logic required to cycle the

machine in the desired manner.

Chapter 6

3

Load Initial

Configuration Values

You load initial values for controlling pressure or

flow, ramp rates, pressure alarms.

Chapter 7

(Used in

Chapters 9 & 10)

4

Load Initial Profile Setpoints

You load Initial setpoints for process control, such

as pressure, velocity, position, and time setpoints.

Chapter 8

(Used in

Chapters 9 & 10)

5

Span your Valves

You span your inject, clamp, and ejector valves.

and set profile pressure alarms.

Chapter 9

6

Tune your Machine for

Producing Parts

We discuss topics to consider when tuning your

machine.

Chapter 10

7

Troubleshoot the QDC

Module with LEDs

We present a troubleshooting table based on LED

indicator conditions

Chapter 11

Important: Throughout the rest of this manual, we refer to system

pressure during profile or axis movement as corresponding to:

inject

pressure,

or

clamp pressure, or

ejector

pressure

All three are the pressure measured at input 2 of the QDC module.

For additional information, refer to System Pressure in chapter 1.

Overview of Procedures