Complete your sensor configuration – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 52

Configure the QDC Module's I/O

Chapter 3

3-8

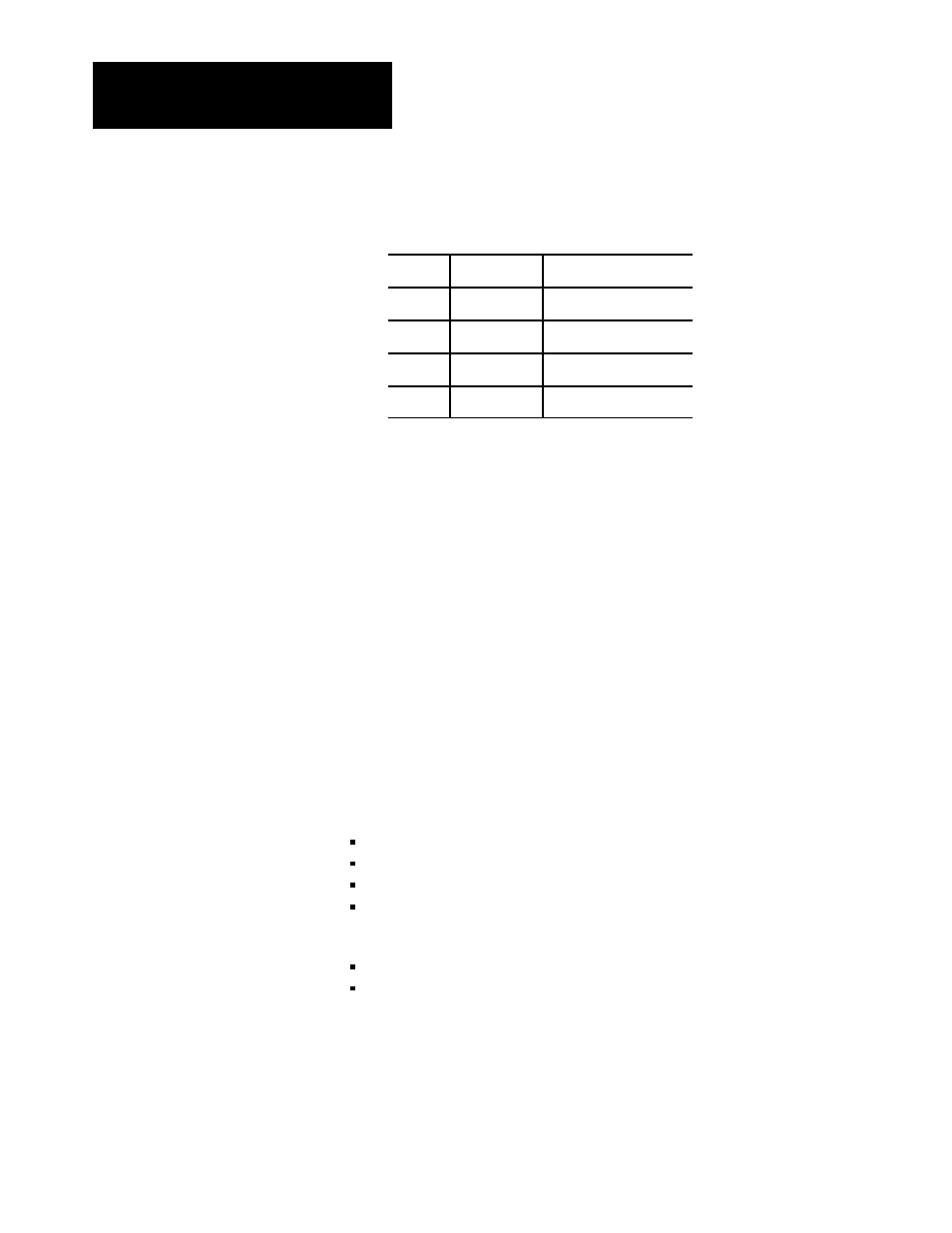

Follow this procedure to actuate the ram (screw), clamp, and ejector:

1. Enter values in words DYC09-12 that result in no motion.

Output:

In Data Word:

At ProĆSet 600 Address:

1

DYC09

N40:121

2

DYC10

N40:122

3

DYC11

N40:123

4

DYC12

N40:124

2. Enable set-output operation by entering a 1 in DYC01-B08

(B34/392). The QDC module sets outputs 1-4 to percentage values

that you entered in DYC09-12 respectively.

Important: The DYC is constantly transferred to the QDC module by

Pro-Set 600 software, so changes you make to %-output values are

immediately implemented.

3. With your programming terminal, slowly change the %-output value

of each output, one at a time, as you observe the corresponding

actuator movement.

4. Increase the %-output value until you reach a safe actuator speed to

use in the next procedure.

Complete the procedure for configuring the QDC module to match its

sensors by spanning them over their intended range with the machine in

operation. Here we describe how you determine:

ram (screw) position sensor values

system pressure sensor values

clamp position sensor values

ejector position sensor values

In the procedures that follow, measure and record:

min/max positions and corresponding signal values

min/max system pressure and corresponding signal values

After determining these values from the procedures, write them down on

Worksheet 3-E.

Important: You must complete this configuration before proceeding to

any other chapters on module configuration.

Complete your Sensor

Configuration