Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 212

Span Your Valves

Chapter 9

9-46

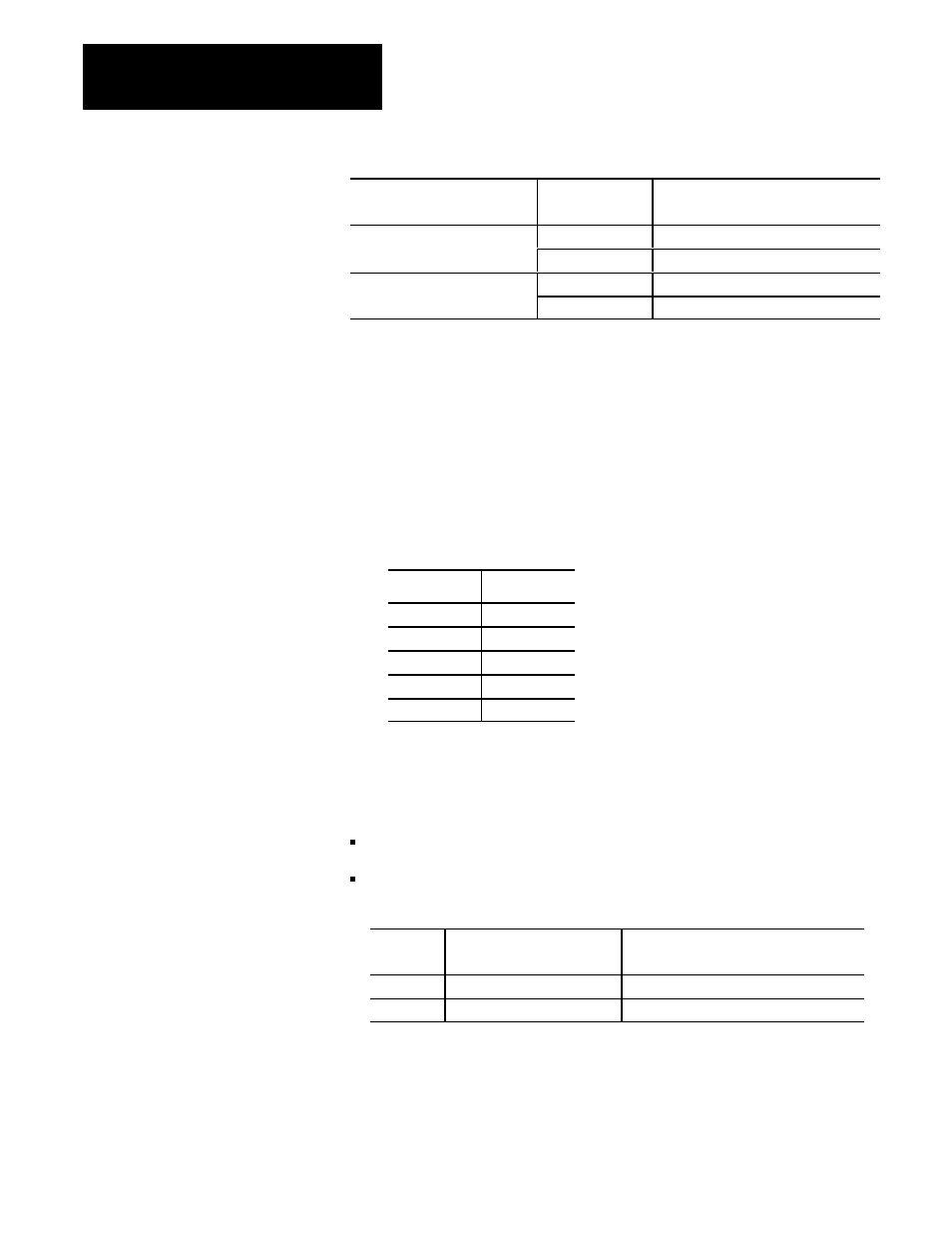

If:

And Your Selected

Valve is:

Then change FOC44

(N43:340) as follows:

OPS13 was less than OPC13

Direct Acting

Increase in 5% steps

Reverse Acting

Decrease in 5% steps

OPS13 was more than OPC13

Direct Acting

Decrease in 5% steps

Reverse Acting

Increase in 5% steps

To do this: change FOC44, download the FOC block, and repeat steps 1-3.

Do this as necessary.

Important: If downloading from your programming terminal, download

FOC followed by OPC with download bits B21/16 and 20 (chapter 4).

4.

Copy final FOC44 (N43:340) into SOC44, TOC44 and OSC44

(N43:400, 460, and 520), and download these changes.

Important: If downloading from your programming terminal, download

FOC, SOC, TOC and/or OSC followed by OPC (chapter 4).

To download:

Set B21/

FOC

16

SOC

17

TOC

18

OSC

19

OPC

20

What You Have Accomplished

The valve spanning procedure you just completed has defined the:

range of pressure available during any clamp open profile

end-of-range maximum and minimum signal levels for linear control of

the clamp open pressure valve in open-loop control.

For this

range limit

When trying to obtain the

pressure in:

The QDC module drives the selected

pressure valve to % output signal in:

Minimum

FOC41,SOC41,TOC41,OSC41 FOC43, SOC43, TOC43, and OSC43

Maximum

FOC42,SOC42,TOC42,OSC42 FOC44, SOC44, TOC44, and OSC44

Now, for all open-loop pressure profiles for clamp open, the QDC module

assumes a linear relationship between clamp pressure and signal output.