Enter and download your worksheet values – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 126

Load Initial Profile Setpoints

Chapter 8

8-9

4. Record your FCC end-of-segment position setpoints for CPC11, 14,

and 17 on Worksheet 8-A.

We recorded zero for the remaining position setpoints on Worksheet 8-A.

The valve spanning procedures in chapter 9 require these initial values.

We help you select correct final values for your application in chapter 10.

For additional information, refer to Section 3 of the Plastic Molding

Module Reference Manual (publication 1771-6.5.88).

TonnageĆcomplete Pressure Setpoint

(CPC63)

The QDC module compares clamp pressure with this value, and sets status

bit SYS03-B02 when clamp pressure equals or exceeds this value.

We recorded zero for the tonnage watchdog timer preset.

The valve spanning procedures in chapter 9 require this initial value. We

help you select correct final values for your application in chapter 10. For

additional information, refer to Section 3 of the Plastic Molding Module

Reference Manual (publication 1771-6.5.88).

After you determine initial values and record them on Worksheet 8-A, you

are ready to proceed. Refer to procedures in chapter 4 if necessary.

Important: Be sure that you do not alter any setpoints, and that you enter

each and every setpoint exactly as on the worksheet.

1. Enter all worksheet values into your PLC-5 data table.

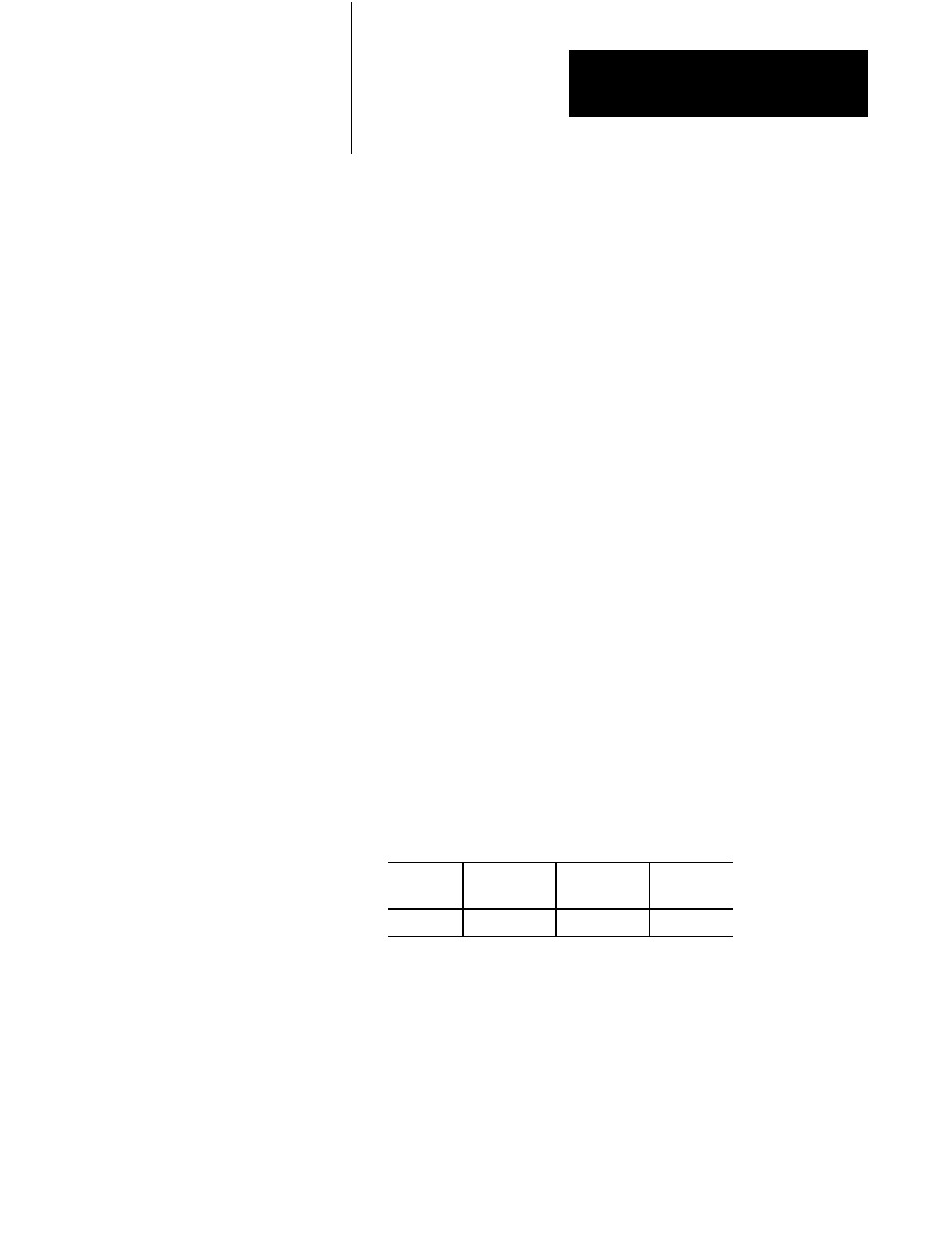

2. Download command blocks to the QDC module. We repeat the CPC

block download data.

Block to

Download:

ProĆSet 600

Block ID:

Download

Command Bit:

Companion

Block:

CPC

07

B21/6

none

3. Check SYS61 and SYS62 for programming error. Correct as needed.

Enter and Download Your

Worksheet Values