Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 51

Configure the QDC Module's I/O

Chapter 3

3-7

To finish configuring the QDC module, you actuate the ram (screw),

clamp, and ejector axes with the QDC module’s set-output operation that

applies percentage values to your QDC module’s outputs to move the

actuator in a controllable fashion. To do this, you apply a %-output signal

to a module output so you can move the actuator over its intended range.

ATTENTION: Do not rely on pressure valves connected to the

QDC module for pressure relief. Use them only for pressure

control below the setting of the system pressure-relief valve.

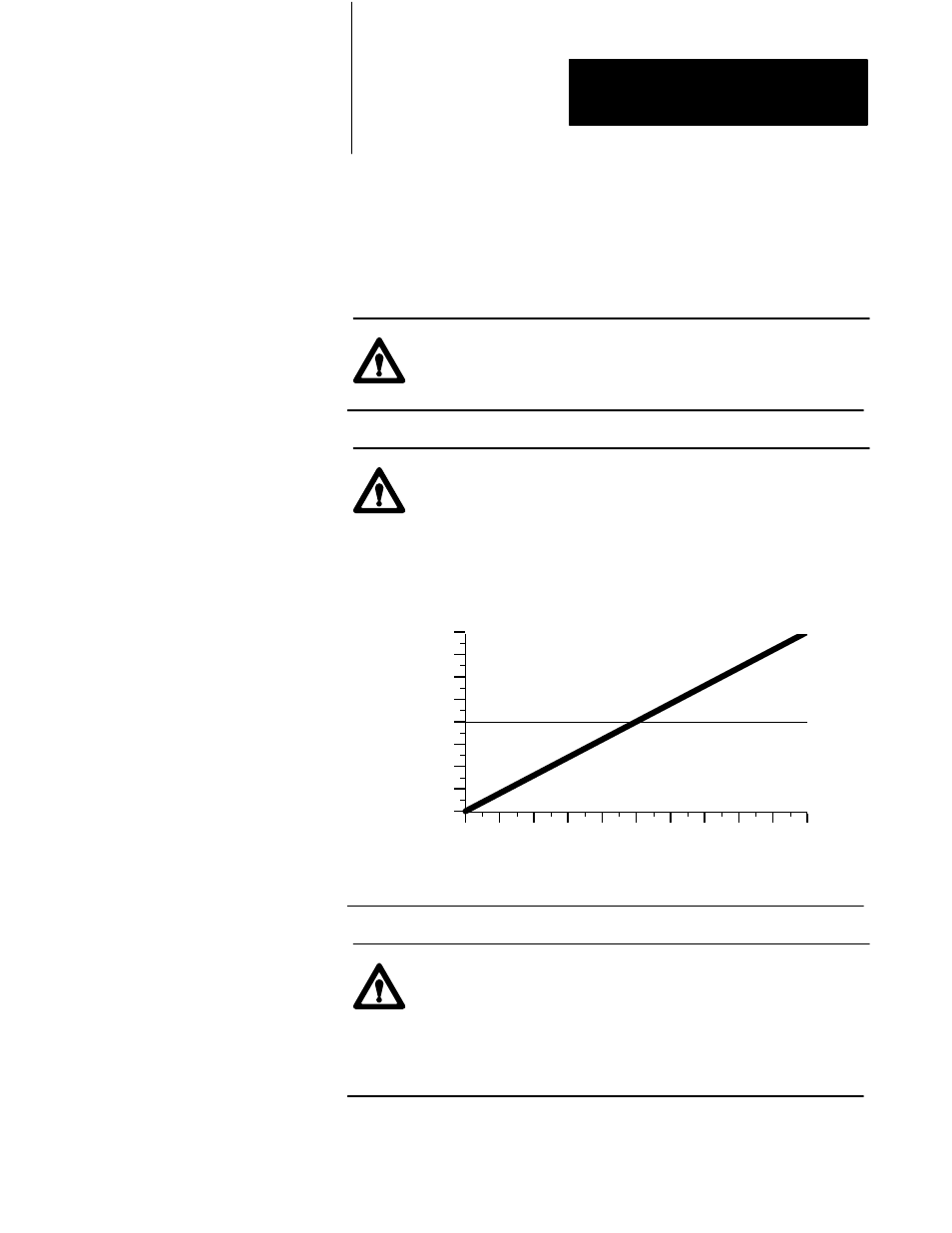

ATTENTION: A value of zero in set-output words

N40:121-124 does not necessarily correspond to zero pressure

or flow. If you configured jumpers E11, E12, E15, or E16 for

bi-directional valve operation, an output of 0% gives –10V dc,

50% gives 0V dc (see chart). Amplifier electronics or

spool-null offsets may also allow pressure or flow at zero volts

signal input. Consult your valve and amplifier specifications.

% Output Requested

Output V

oltage

-10

-8

-5

-3

0

3

5

8

10

0

10 20 30 40 50 60 70 80 90 100

ATTENTION: As soon as you enable set-output operation, the

QDC module’s outputs drive the connected valves according to

the values you entered into DYC09-12 (N40:121-124). Be sure

these values RESULT IN NO MOVEMENT until you adjust

them one-at-a-time with your programming terminal in the

procedures that follow.

Use SetĆoutput Operation to

Move the Ram (screw),

Clamp, and Ejector