System pressure, 1ć15 – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 27

Overview of Inject, Clamp, and Eject Mode

Chapter 1

1-15

Other Eject Features

The QDC module gives you the following additional features:

Multiple Cycles – the ability to repeat the ejector cycle a number of

times, changing from advance to retract determined either automatically

or by command from your PLC program

Ejector Forward Dwell - the ability to pause after completing the first or

last advance stroke. Use this feature so a robot can pick off a part when

ejectors are fully extended

Ejector “Tip” Strokes - the ability to shake the part off the ejector. You

may program interim single-segment advance and retract tip strokes that

occur after the first advance stroke and before the last retract stroke

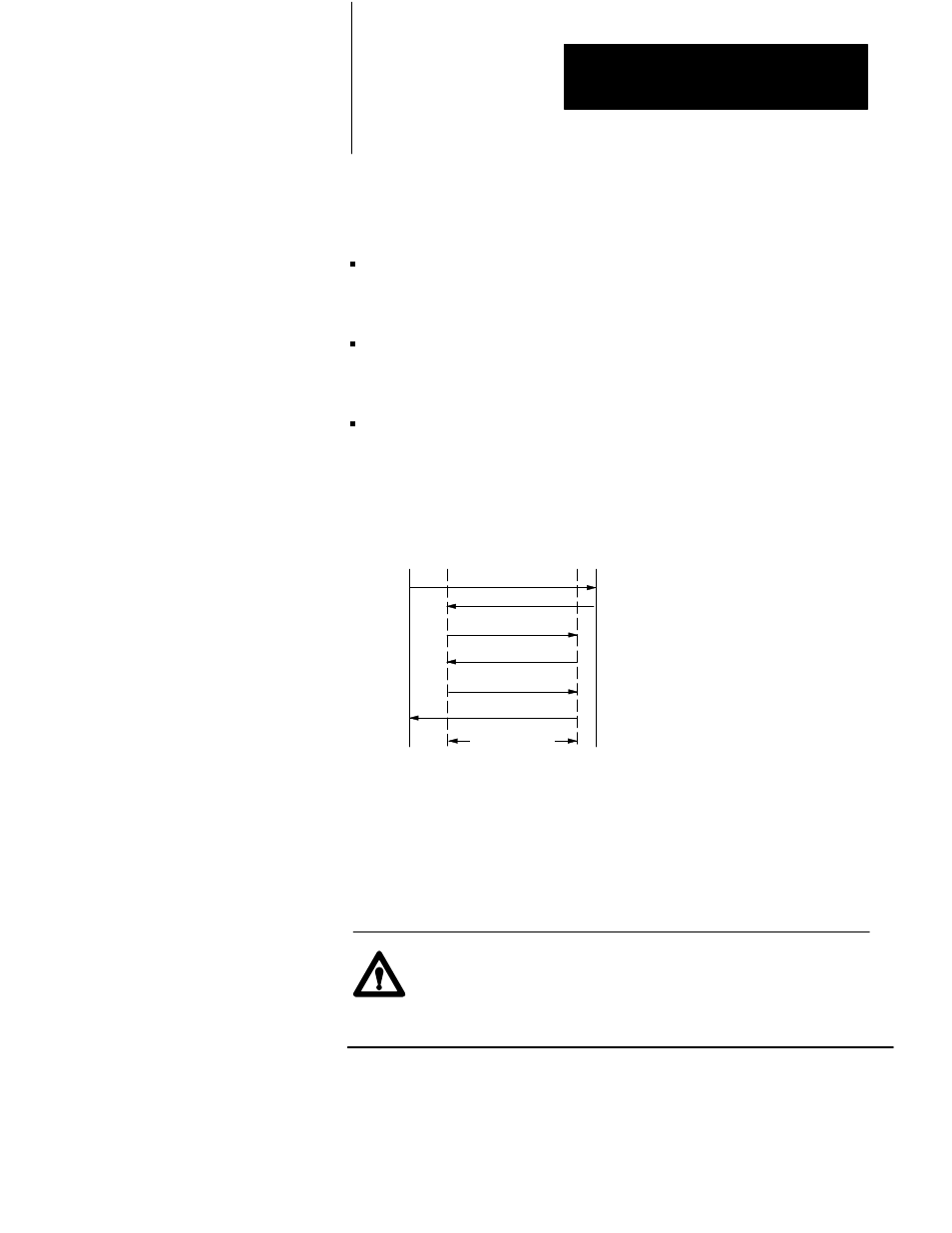

Figure 1.19

Advance, Retract and Tip Strokes

Full

Retract

Full

Advance

Tip Strokes

First Full Advance

Tip Advance

Tip Retract

Last Retract

Ejector Forward Dwell

:

:

Tip Retract

Ejector Forward Dwell

We define system pressure for the Inject, Clamp, and Eject mode as the

pressure continuously detected by the single pressure sensor connected to

the QDC module at input 2. Depending on machine hydraulics, a single

pressure valve may control inject, clamp, and/or eject mode profiles.

ATTENTION: Your control system may not work as expected

with possibly machine damage if you attempt to control a

pressure profile of a phase (inject, clamp, or eject) not

hydraulically plumbed for pressure control.

System Pressure