Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 61

Configure the QDC Module's I/O

Chapter 3

3-17

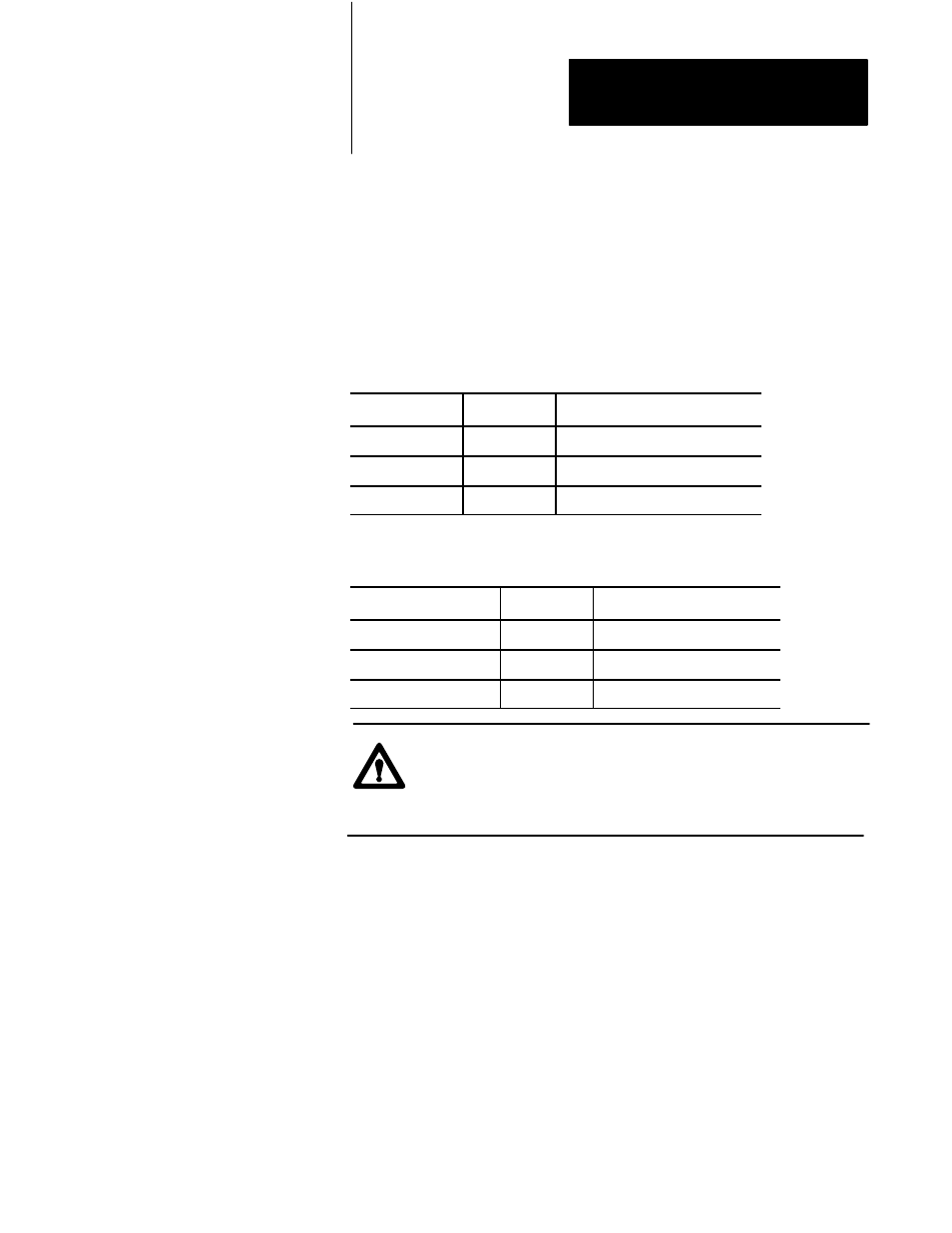

Configure Digital Filters for Position Inputs

You may enable an optional digital filter on position inputs to reduce

electrical noise from a potentiometer-type position sensors or picked up by

your input circuits.

To determine if you need a digital filter, move the ram (screw), clamp,

and/or ejector very slowly. With your programming terminal, look for

erratic position numbers reported for ram (screw), clamp, and/or ejector

position by examining these words:

For this Input:

In Word:

Look at this ProĆSet 600 Address:

Ram (Screw)

SYS25

N40:177

Clamp

SYS27

N40:179

Ejector

SYS28

N40:180

To determine the time constant (00.10 sec max), start with a small value

such as 00.01. A value of zero disables the filter.

To Filter this Input:

In Word:

Enter a Filter Time Constant in:

Ram (Screw)

MCC16

N40:12

Clamp

MCC30

N40:26

Ejector

MCC44

N40:40

ATTENTION: Increasing the value of the time constant

decreases the QDC module’s capability to respond quickly to

travel limits and/or to accurately locate programmed positions.

We recommend that you keep the time constant under 00.10.

For example, with a clamp velocity of 2 inches/sec, a 00.01 time constant

allows a 0.20 inch travel before the QDC module can react to a travel limit.

Important: If you have a noisy potentiometer-type position sensor and

digital filtering slows the QDC module’s response time too much, consider

replacing the sensor with a non-contact, linear-displacement type.

Download time constants to the QDC module using the procedures

presented earlier in this chapter.