Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 249

Tune Your Machine

Chapter 10

10-21

IPC57 – Ram Pressure Limit for Pressure-limited Velocity Control.

When ram (screw) pressure reaches this limit and IPC58 and 59 allow it,

the QDC module switches control from velocity to pressure control.

Consider the following when determining this setpoint. Use a value:

considerably below the mold flash point to let the QDC module

gain pressure control before flashing the mold

less than the injection transition pressure in IPC62

The QDC module may switch back and forth between velocity and

pressure control excessively. To guard against this condition, you can use

setpoints IPC58 and IPC59.

IPC58 – Start of Zone for Pressure-limited Velocity Control.

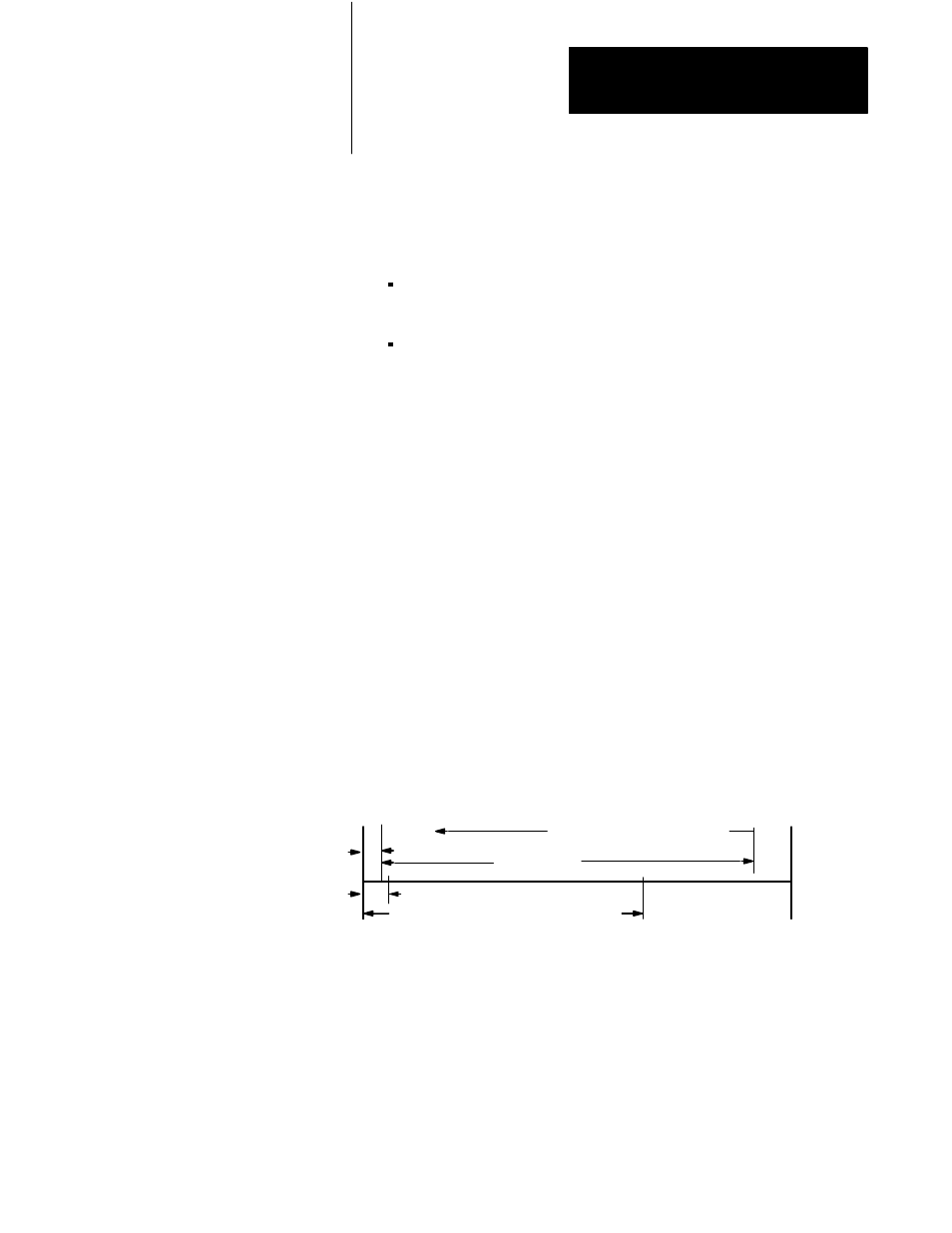

This position defines the zone measured from mold end in which the QDC

module allows a change from velocity to pressure control (figure 10.2).

Pressure limiting can occur after the ram (screw) passes this position. We

recommend a distance of about 50% of shot size. Smaller distances

increase the possibility of flashing the mold.

IPC59 – Time Delay for Pressure-limited Velocity Control.

This delay starts at change of control. Use it to avoid changing control to

frequently due to nuisance pressure or velocity spikes. We recommend an

initial delay of 8 to 12 ms. Too small a delay induces oscillation between

pressure and velocity control resulting in poor control and excessive

hydraulic wear. Too large a delay results in poor control and mold

flashing.

Figure 10.2

Zone for PressureĆlimited Velocity Control

Backpoint

Mold end

Cushion

Shot Size

Transition Position

Zone for PressureĆlimited Velocity Control

Direction of Ram (Screw) Travel

IPC58