Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 242

Tune Your Machine

Chapter 10

10-14

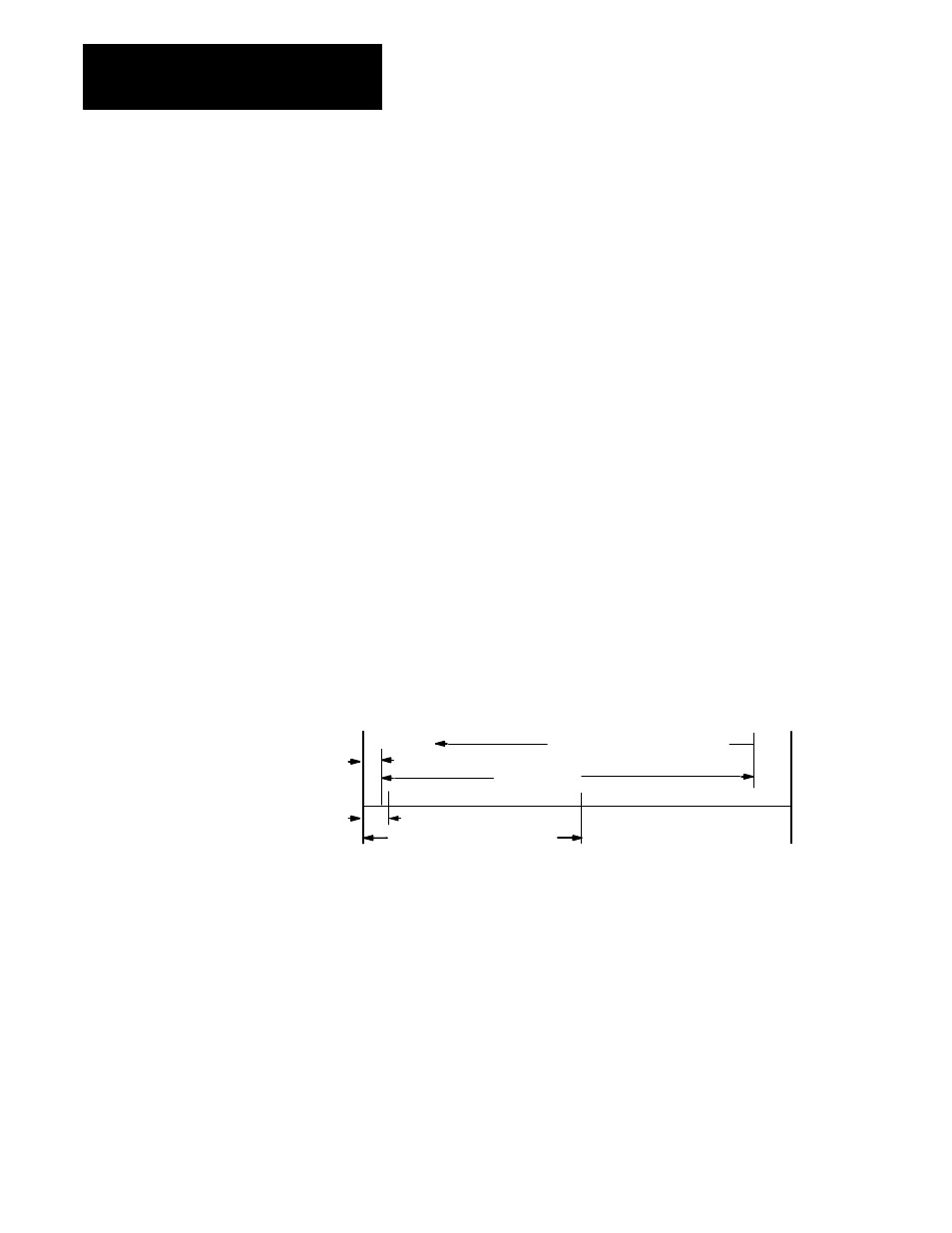

Ram (Screw) Position for Transition

(IPC61)

This position setpoint (measured from mold end) determines where

injection ends and pack (or hold) begins (figure 10.3). Enter a position

value equal to or slightly greater than the top-of-cushion position,

depending on whether your part requires additional plastic compressed into

the mold during pack and hold.

Ram (Screw) Pressure for Transition

(IPC62)

If actual ram (screw) pressure during injection exceeds this setpoint, the

QDC module transitions to the pack phase. Typically you enter a value

less than mold flash pressure.

Start of Zone for Pressure Transition

(IPC64)

A non-zero value (measured from mold end) forces the QDC module NOT

to transition on pressure until the ram (screw) reaches this position (figure

10.3). Use this setpoint to prevent nuisance pressure transitions due to

pressure spikes during the early phases of the injection profile. Typically,

you can inhibit pressure transitions over 50% of shot size without flashing

the mold.

Figure 10.3

Static Setpoints for the Injection Profile

Backpoint

Mold end

Cushion

Shot Size

Transition Position

Zone for Pressure Transition

Direction of Ram (Screw) Travel

IPC64

Time Limit for Transition

(IPC60)

The QDC module transitions from injection to pack (or hold) if the total

injection profile time equals or exceeds this setpoint. Use this value as a

safety watchdog if some condition prevents the injection profile from

completing in a timely fashion.