Referenced worksheets, Span your valves chapter 9 – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 169

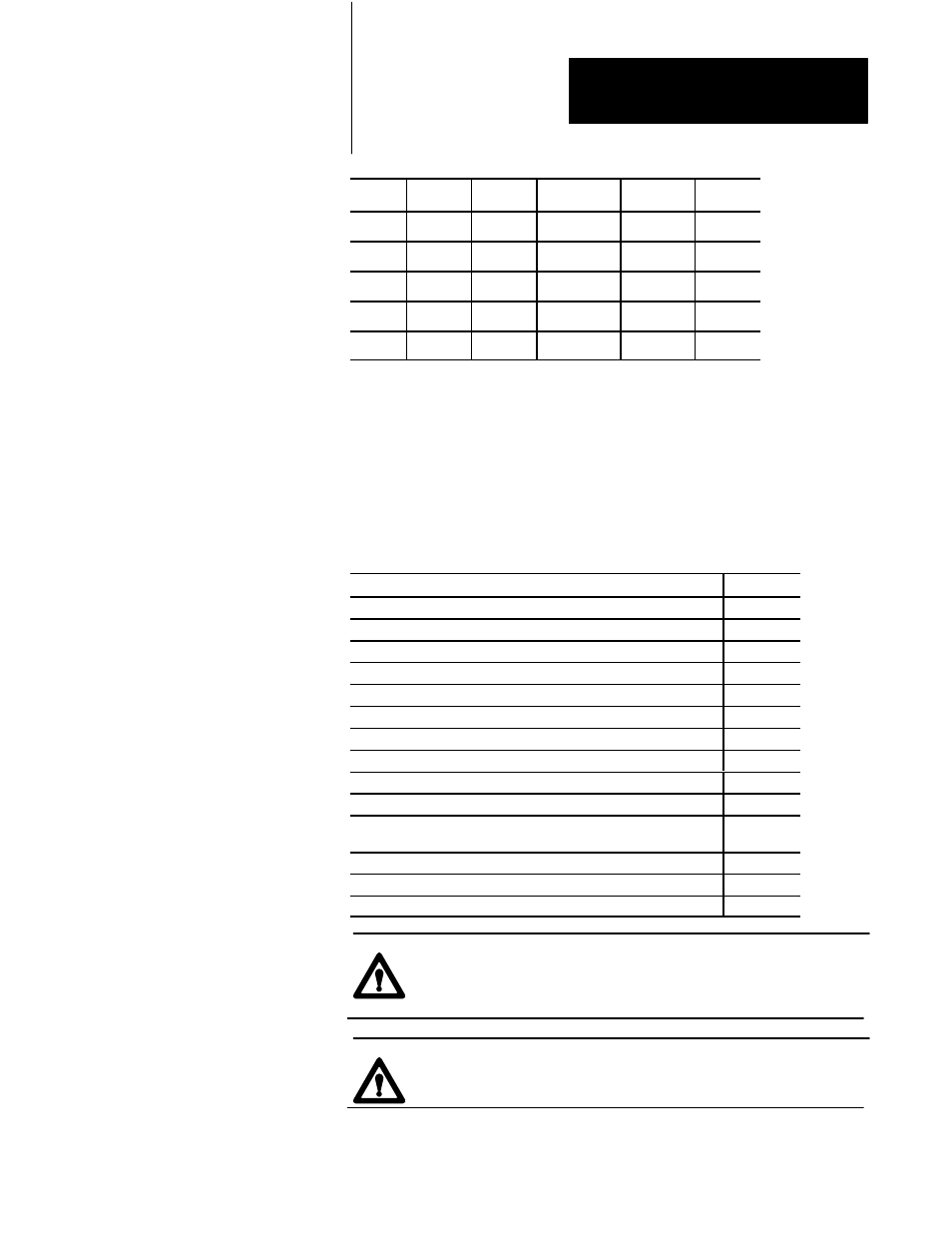

Span Your Valves

Chapter 9

9-3

Profile

Not Used

Open Loop

Closed Loop

Velocity

Pressure

SOC

TOC

OSC

EAC

ERC

If necessary, review system pressure, hydraulic circuits and corresponding

control options presented in chapter 2 under the sections System Pressure

and Example Hydraulic Circuits, to verify that your application is

hydraulically correct.

The following table lists worksheets containing initial values from chapters

7 and 8 that you will use in this chapter.

Data Block:

Worksheet:

Clamp Low Pressure Close Configuration Block (LPC)

7ĆB

Clamp Close Configuration Blocks (FCC, SCC, TCC)

7ĆA

Clamp Close Profile Block (CPC)

8ĆA

Injection Configuration Block (INC)

7ĆC

Injection Profile Block (IPC)

8ĆB

Pack Configuration Block (PKC)

7ĆD

Hold Configuration Block (HDC)

7ĆE

Pack/Hold Profile Block (HPC)

8ĆC

Plastication Configuration Block (PLC)

7ĆF

Plastication Profile Block (PPC)

8ĆD

Clamp Open and Open Slow Configuration Blocks

(FOC, SOC, TOC, OSC)

7ĆG

Clamp Open Profile Block (OPC)

8ĆE

Ejector Configuratiion Blocks (EAC, ERC)

7ĆH

Ejector Profile Block (EPC)

8ĆF

ATTENTION: As with any machine start-up, install a test

mold. Programming errors, configuration errors, or hydraulic

problems could lead to personal injury and/or machine damage.

ATTENTION: Make sure all machine guards and shields are in

place before proceeding to guard against personal injury.

Referenced Worksheets