System command and status blocks – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 63

Overview of Remaining

Configuration Procedures

Chapter 4

4-2

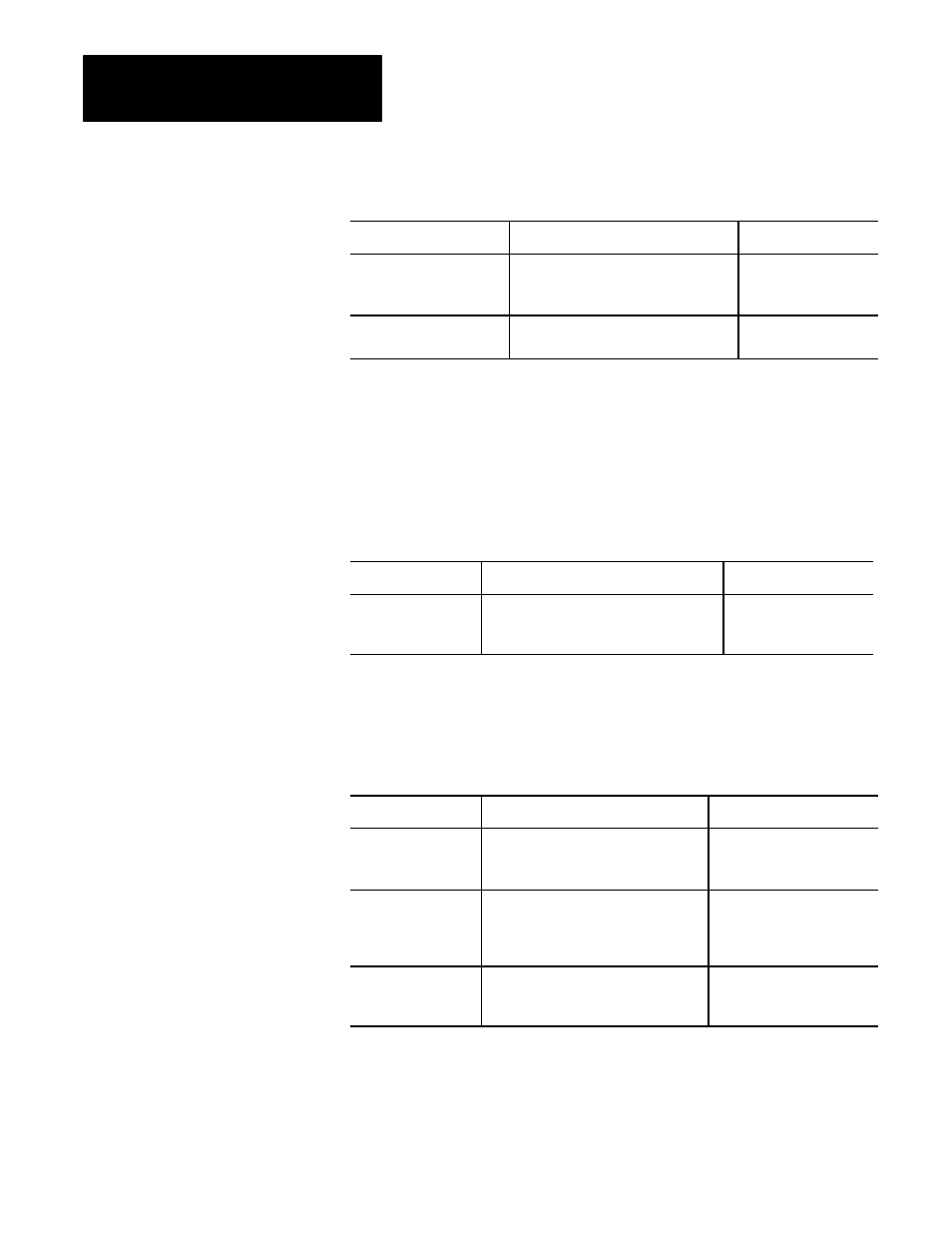

There are two types of command blocks, presented in the following table:

Type of Command Block:

Which Contains:

Examples:

Configuration

Information necessary to configure your

module to run a certain portion of a profile.

Valve spanning

information for the 1st

clamp close profile.

Profile

Actual process setpoints necessary to

produce a desired part.

1st clamp close profile

operating setpoints.

Status Blocks

The QDC module returns critical operating status and values to the PLC-5

data table through status blocks. Like configuration blocks, status blocks

are areas of PLC-5 data table. Status blocks, however, contain actual

machine operation information rather than machine setpoints and action

commands.

Type of Block:

Which Contains:

Examples:

Status

Information about machine operation and

QDC module operating status.

The molding machine is

currently performing an

injection operation.

The Module Configuration Block (MCC), Dynamic Command Block

DYC), and the System Status Block (SYS) are system data blocks because

of functions they perform:

Type of Block:

Description:

Examples:

Module Configuration

(MCC)

Contains configuration information used

throughout all phases of machine

operation.

Sensor spanning information

and global alarm setpoints.

Dynamic Command

(DYC)

Includes all commands necessary to jog,

run, and stop any applicable machine

phase or operation.

Command to start the injection

phase.

System Status

(SYS)

Returns to the PLCĆ5 processor

information relevant to common module

parameters.

Actual voltages and

engineering units read at the

four QDC module inputs.

System Command and

Status Blocks