Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 125

Load Initial Profile Setpoints

Chapter 8

8-8

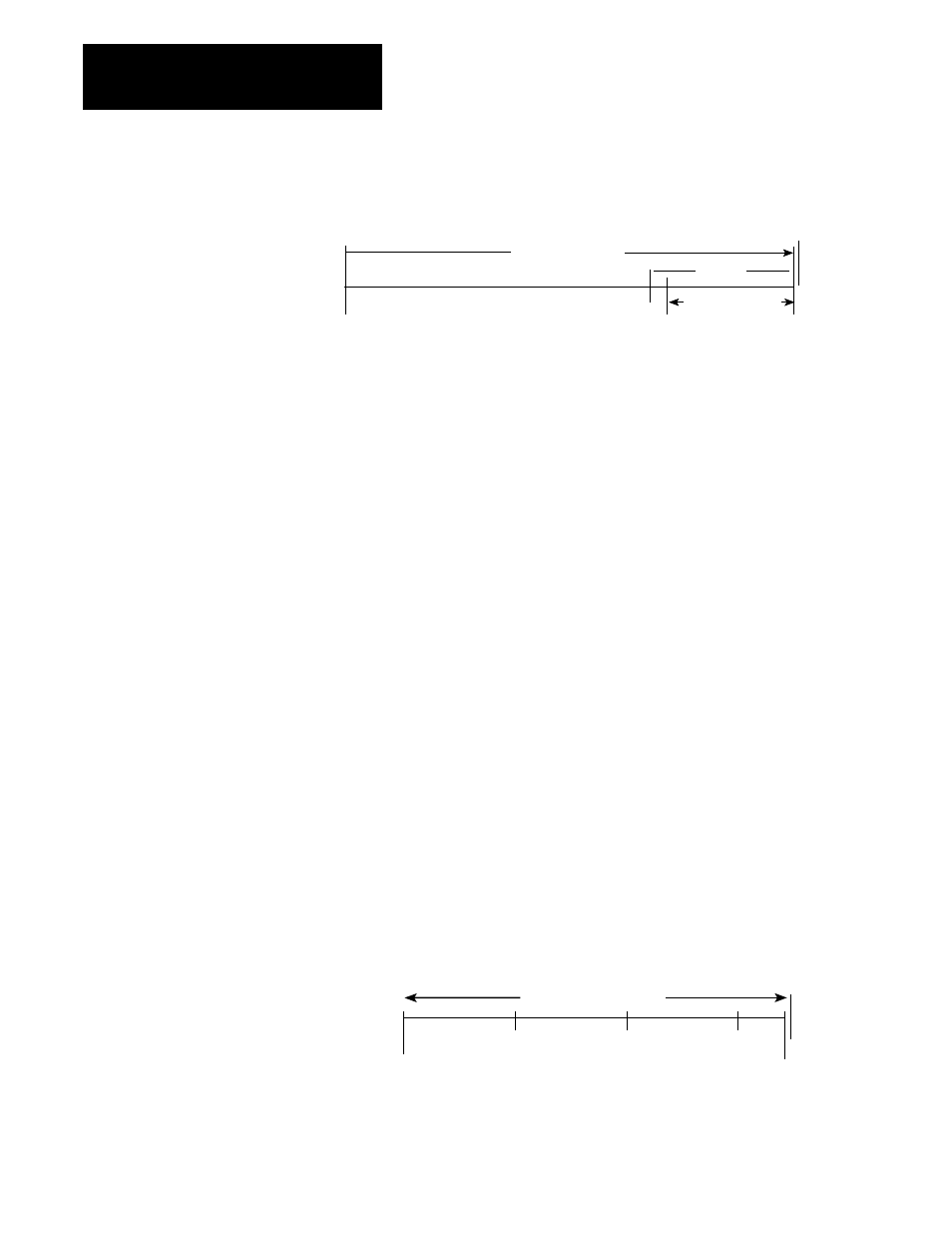

Figure 1.1

Example Setpoints for Mold Safe (CPC62) and Start Protection Zone (CPC61)

(OPC62)

Fully Open Mold Safe

Clamp Motion

zero

(CPC61) (CPC62)

LPC

Protection Zone

We recommend an initial value larger than the start LPC position you

would typically use during normal machine operation.

Record a value for CPC61 that is a safe distance from mold safe (CPC62)

on Worksheet 8-A.

The valve spanning procedures in chapter 9 require this initial value. We

help you select the correct final values for your application in chapter 10.

For additional information, refer to Section 3 of the Plastic Molding

Module Reference Manual (publication 1771-6.5.88).

EndĆofĆsegment Position Setpoint

(CPC11, 14, 17, 20, 23, 26, 29, 32, 35, 38)

Configure only the first clamp close profile segments.

Determine end-of-segment position setpoints for first clamp close as

follows:

1. Jog the mold to its full open position and observe the value in SYS27

(N40:179).

2. Subtract the value you recorded for Start LPC Position Setpoint

(CPC61) from SYS27.

3. Divide this difference into three equal sections. The dividing line of

each section should be recorded for the end-of-segment position

setpoints for segments 1, 2, and 3.

Important: Measure end-of-segment positions from zero (mold safe).

Fully Open

FCC Seg 1

(CPC11)

Mold Safe

(CPC62)

FCC Seg 2

(CPC14)

FCC Seg 3

(CPC17)

(CPC61)

Clamp Travel Range

zero