Procedure to determine and record initial values, 7ć19 – Rockwell Automation 1771-QDC, D17716.5.93(Passport) PLASTIC MOLDING MODULE User Manual

Page 105

Load Initial Configuration Values

Chapter 7

7-19

Follow this procedure to complete each worksheet:

1.

Decide which profiles you will and will not use.

2.

Read the text for the subject parameter.

3.

Determine your initial value for that parameter.

Important: If you need additional information when determining your

initial values, refer to the same configuration blocks in Section 3 of the

Plastic Molding Module Reference Manual, publication 1771-6.5.88.

Important: In the text that follows the worksheets, configuration words

that require the subject parameter are listed under the title of each subject

parameter. The address codes identify the configuration blocks that uses it.

4.

Locate each worksheet that requires the subject parameter.

5.

Record the value on the corresponding line(s) in the worksheet.

Important: Block identifier codes are already recorded for you.

Selected Valve for Velocity Control

(FCC02, SCC02, TCC02, INC02, FOC02, SOC02, TOC02, OSC02, EAC02, ERC02)

The QDC module can control ram (screw), clamp, and ejector movement

using a velocity vs. position algorithm. Since you can connect up to four

valves to your QDC module, you must tell it which valve to use for

velocity (flow) control.

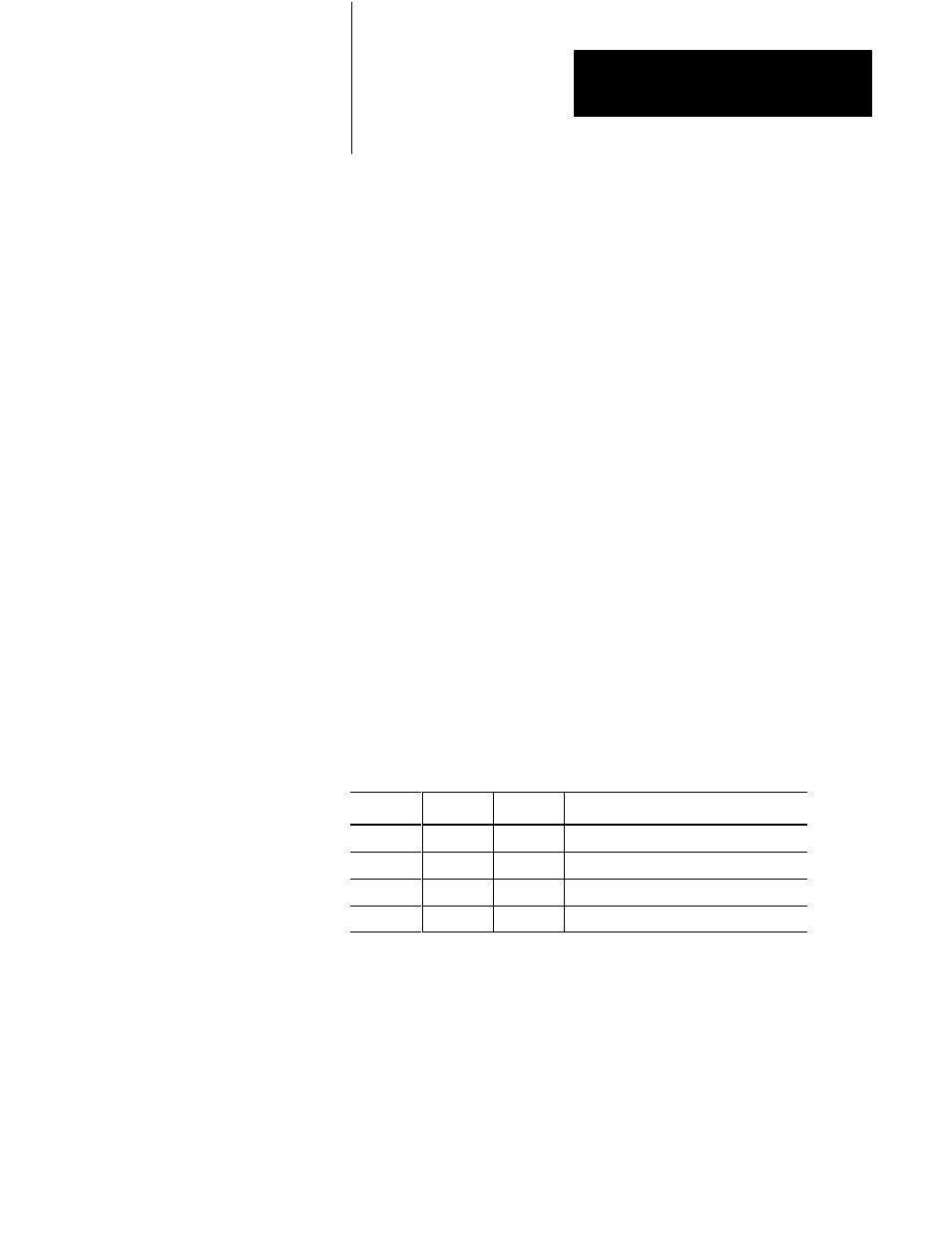

B02

B01

B00

Selects:

0

0

0

Output #1 Used for Velocity Control

0

0

1

Output #2 Used for Velocity Control

0

1

0

Output #3 Used for Velocity Control

0

1

1

Output #4 Used for Velocity Control

Record the appropriate bit selections for your valve configurations in the

control word of applicable worksheets.

Procedure to Determine and

Record Initial Values

Determine Bit Selections:

Assign Module Outputs for

Your Control Valves