Rockwell Automation 1395 Digital DC Drive FRN 5-10.10/9.30 User Manual

Page 94

Chapter 5

Functional Description

5-8

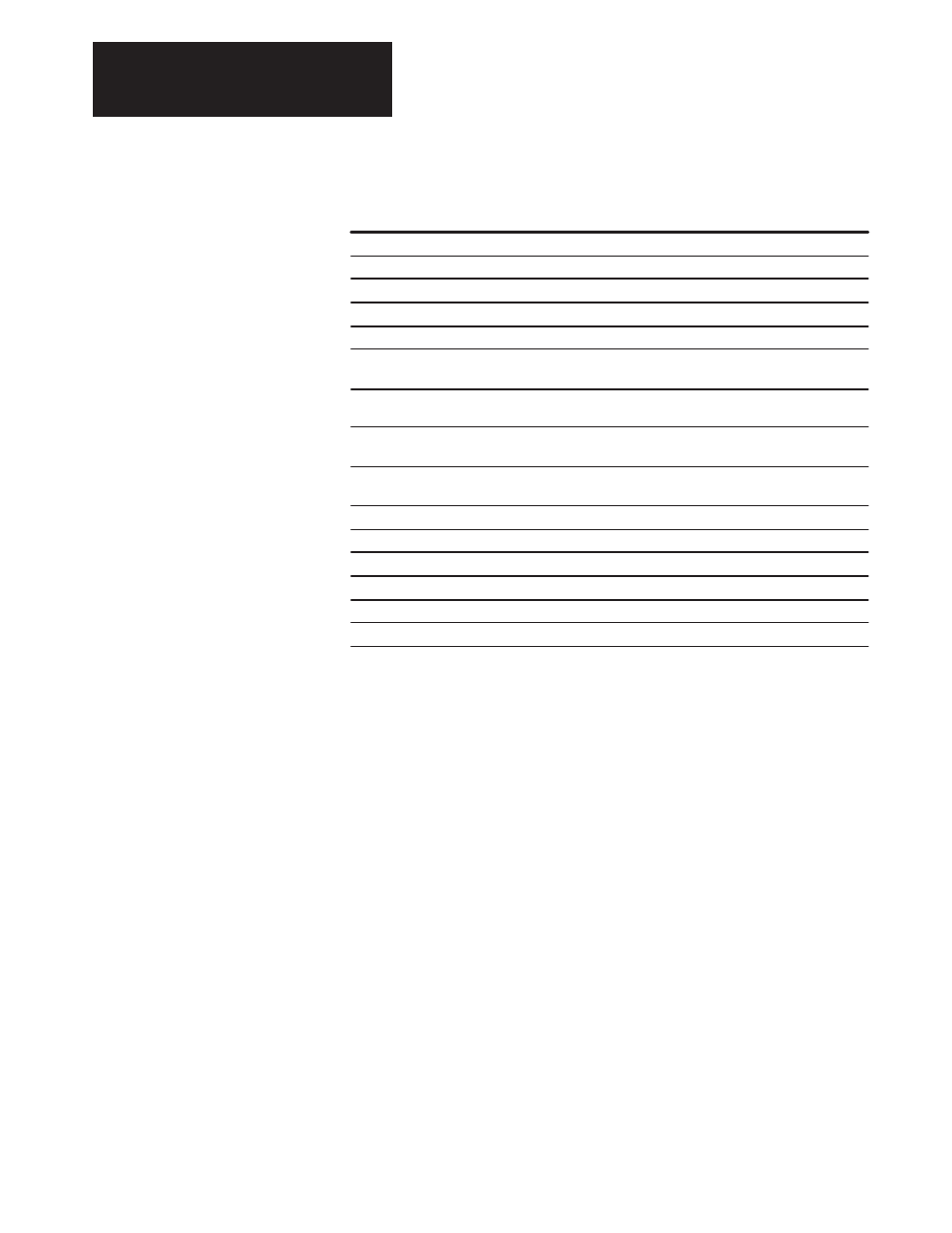

Table 5.A

Control Sink Parameters

Number

150

151

152

153

154

156

157

159

160

161

162

163

164

165

166

Name

Logic Cmd 1

Logic Cmd 2

Logic Cmd 3

Vel Ref Fraction

Vel Ref Whole

Tach Velocity

Torque Reference

Flux Feed Fwd

CEMF Reference

Process Trim Ref

Proc Trim Fdbk

Vel Indirect 1

Vel Indirect 2

Vel Indirect 3

Vel Indirect 4

Function

First 16 Bit Logic Command Word

Second 16 Bit Logic Command Word

Third 16 Bit Logic Command Word (Program Terminal)

External Velocity Reference Fractional Part

External Velocity Reference Whole Part

Tachometer feedback signal coming from analog tach or other

external velocity feedback device

Torue Reference input. Used when drive operates as a torque

regulator.

External flux reference used as a feed forward term in field

regulator.

Counter EMF Reference. Used when drive is operated as a

torque regulator

Process Trim Reference Input

Process Trim feedback derived from external sensing device

Indirect parameter, linked to slow Parameter 600

Indirect parameter, linked to slow Parameter 601

Indirect parameter, linked to slow Parameter 602

Indirect parameter, linked to slow Parameter 603

The function of each Sink parameter has been pre-defined and cannot be

changed. For example, Parameter 151 (Logic Cmd 2) has been specifically

set aside for the function of drive logic control. Because each Sink

parameter has been defined for a specific use, each Sink parameter will

have a specific data type and units of measure.

For example, Parameter 151 (Logic Cmd 2) is a 16 bit word where each bit

has been defined for a specific function such as Start, Stop, Close

Contactor, etc. A description of each parameter is provided in Chapter 7.

The specific external control devices which can be interfaced with the

drive are defined by the type of Adapter Boards connected to Microbus

Ports A and B on the Main Control Board. For example, the drive could be

controlled by discrete hardware such as push buttons and pots. In this case,

a Discrete Adapter Board would be required to interface the discrete

control hardware to Port A. If interface with a PLC is desired, a Node

Adapter Board is required in Port B.

Each Adapter Board also has Sink parameters associated with it as shown

in Figure 5.2.