Control boards, 1, 13, 15 figure 3.5, Tb1-5, 6, 7 figure 3.5 – Rockwell Automation 1395 Digital DC Drive FRN 5-10.10/9.30 User Manual

Page 47: Figure 3.5, Figure 3.5 feedback board (a1) overview, Table 3.a feedback board jumpers (see t able 8.j)

Chapter 3

Hardware Description

40 – 100 HP, 230VAC

75 – 200 HP, 460VAC

3-7

Control Boards

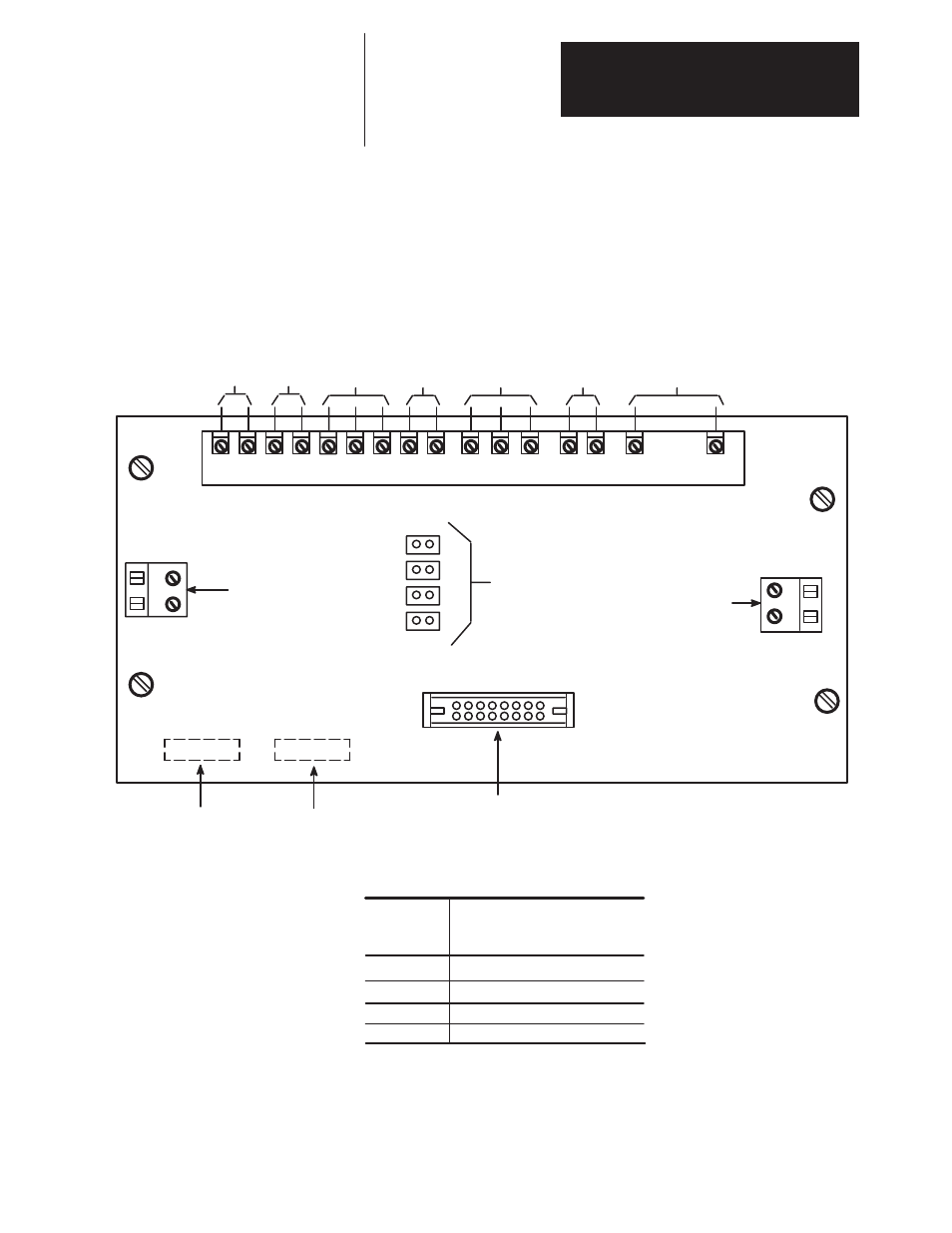

Feedback Board – Figure 3.5 illustrates the major hardware points on the

board. The primary function of the board is to provide scaling and transfer

of feedback signals coming from power bridge devices being sent to the

Power Stage Interface and eventually to the Main Control Board.

Figure 3.5

Feedback Board (A1) Overview

TB2

MFG Revision No.

Spare Part Kit No.

Connection for AC current

feedback burden resistor

(Factory Installed)

1

2

3

1

4

TB1

J2

TB3

Л

Л

5

6

7

8

9

11

13

15

17

18

20

23

J1

3

2

4

Connection for DC current

feedback burden resistor

(Factory Installed)

From DC

Current

Feedback

Sensor TD1

20 VAC

from

1 PT

AC Current

Feedback from

CTs ACT–1 & 2

Field Current

Feedback from

FCT

3 Phase Incom-

ing AC Line

voltage Feed-

back

From Heatsink

Thermoswitch

HST

DC Armature Volt-

age Feedback

Connection to Power

Stage Interface

Jumper Selection

for Field Current

Feedback Scaling

(By User At Start-Up)

Table 3.A

Feedback Board Jumpers (see Table 8.J)

J1

Jumper

Position

40 – 100 HP 240 VDC

75 – 200 HP 500 VDC

Field Current Range

9.1 – 21.2 ADC

4.1 – 9.2 ADC

1.1 – 4.2 ADC

0.65 – 1.2 ADC

1

2

3

4