Rockwell Automation 1395 Digital DC Drive FRN 5-10.10/9.30 User Manual

Page 26

Chapter 2

Hardware Description

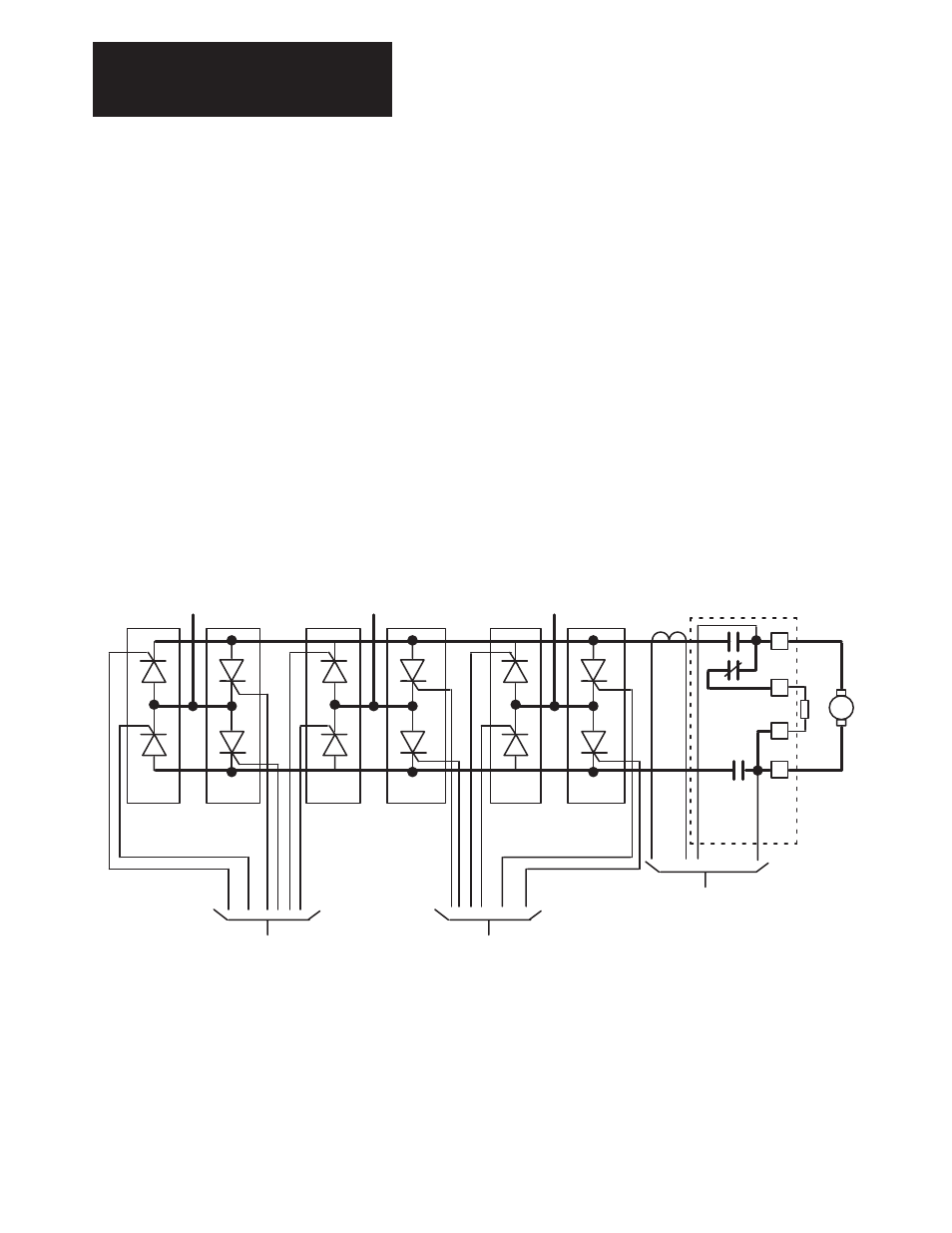

1 – 30 HP, 230VAC 2 – 60 HP, 460VAC

2-4

Surge Suppression – Surge suppressor MOV1 to MOV4 on the Power

Board protects the armature power bridge from line voltage spikes and line

surges.

Line Reactor – A reactor mounted outside the drive is used to protect the

power bridge SCRs from rapid rate of current changes (di/dt).

SCR Packaging – SCR packaging in the 1395 in bridge ratings 3.6 – 110A

(1 – 60 HP) consists of 2 SCRs per module. The regenerative construction

has 6 SCR blocks PM1 through PM6. The non regenerative construction

has 3 SCR blocks PM1, PM3 and PM5. Refer to Figure 2.3.

Pulse Transformers – Pulse Transformers on the Power Board provide

the gate firing pulses and voltage isolation for the armature SCRs.

Voltage Transient Protection – RC networks contained on the Power

Board are used to protect the SCRs against voltage transients (dv/dt).

DC Bus Snubbers – DC Bus Snubbers are used on 3.6 – 19 A units only.

DC Current Sensing – DC overcurrent sensing is provided using DC

transducer TD1.

Figure 2.3

Armature Bridge Components (OUTPUTS)

A1

PM1

To PSI/

Switcher

Board

3F

TD–1

L1

L2

G1

L3

G2

1F

4F

1R

4R

G2

G1

PM2

G1

G2

PM3

PM4

6F

PM5

PM6

G1

6R

3R

G2

G1

G2

5F

2F

2R

5R

G2

G1

A2

DB Resistor

M1

To Power

Board

To Power

Board

DB2

DB1

A1

A2

DC Contactor – Output of the armature bridge is connected to the DC

motor through the main DC contactor M1 (Fig. 2.3). Coil voltage to M1 is

controlled by contacts from the pilot relay K3 (on PSI/Switcher board) and

external 115VAC control input entering at TB2-2 and 3.

Bridge Output Connections – Bridge output connections labeled A1 and

A2 (Fig. 2.3) correspond to the NEMA standards for connection to the A1

and A2 leads of the DC motor. If dynamic braking is used, the dynamic

braking resistor bank is connected to terminals DB1 and DB2.