Plc-5 example, Plc-5 example -8 – Rockwell Automation 22-COMM-C ControlNet Adapter User Manual

Page 58

5-8

Using the I/O

The Drive I/O Control program (

) defines the I/O needed to

control the drive.

PLC-5 Example

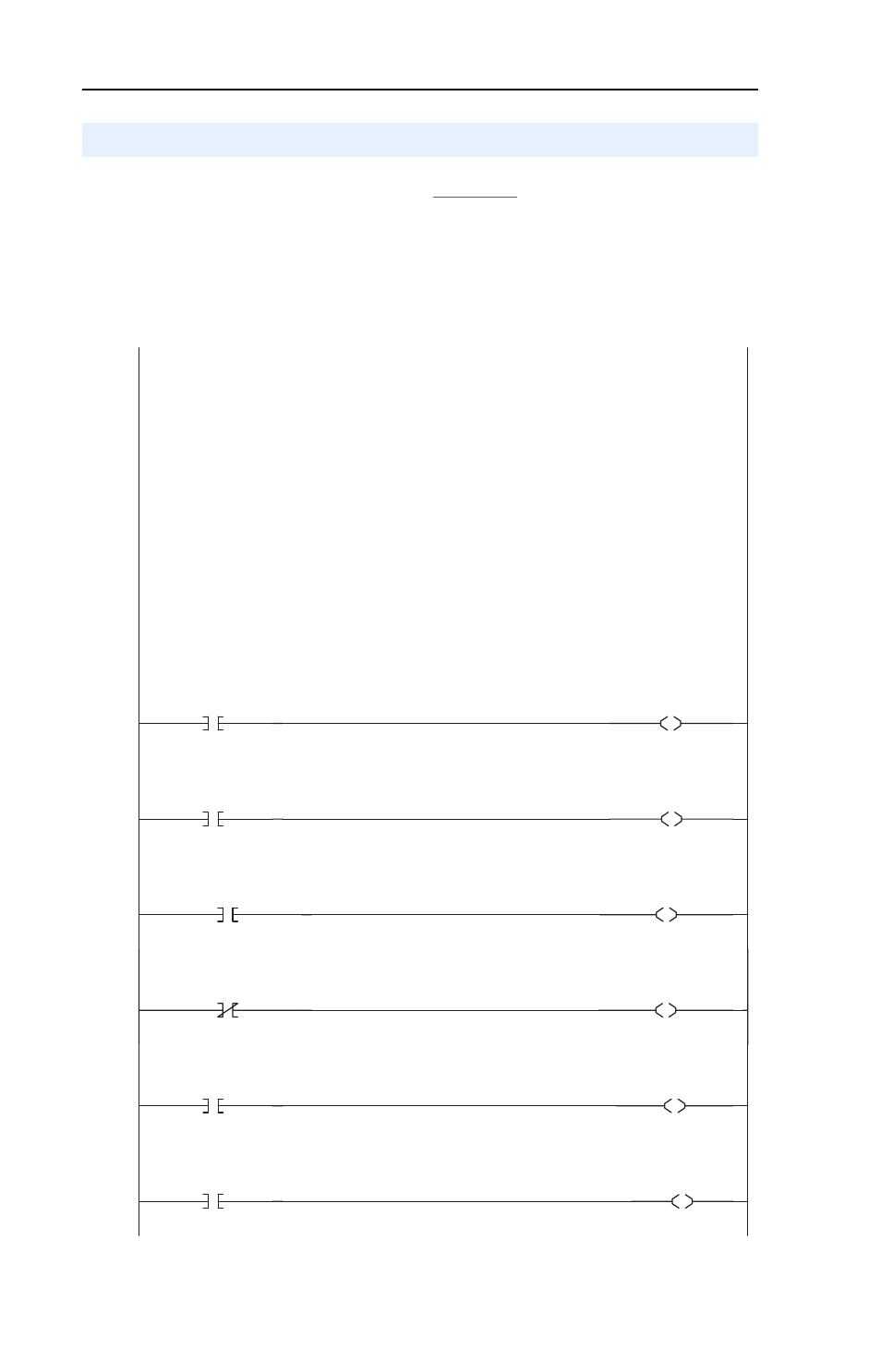

Figure 5.4 PLC-5 Ladder Logic Example for Drive I/O Control

In this example, an operator station is wired into the local PLC-5/40C rack as follows:

O:000/0 Drive Ready

O:000/1 Drive Active

O:000/2 Drive Forward

O:000/3 Drive Reverse

O:000/4 Drive Faulted

O:000/5 Drive At Speed

O:001 Operator Speed Feedback

I:000/0 Stop (Normally

I:000/1 Start (Normally Open Pushbutton)

Open Pushbutton)

I:000/2 Jog (Normally Open Pushbutton)

I:000/3 Clear Faults (Normally Open Pushbutton)

I:000/4 Forward / Reverse Selector Switch

I:001 Operator Speed Reference

In this example, a PowerFlex 40 drive with installed 22-COMM-C ControlNet adapter is mapped as follows:

N9:0 Logic Status N10:0 Logic Command

N9:1 Speed Feedback N10:1 Speed Reference

Rungs 0000 through 0005 move the Logic Status from the drive to the operator station.

0000

N9:0

0

Drive Logic Status

READY

O:000

0

Operator

Drive Ready Status

Display

0001

N9:0

1

Drive Logic Status

ACTIVE

O:000

1

Operator

Drive Active Status

Display

0002

N9:0

3

Drive Logic Status

ACTUAL FORWARD /

REVERSE DIRECTION

O:000

2

Operator

Drive Actual Forward

Status Display

0003

N9:0

3

Drive Logic Status

ACTUAL FORWARD /

REVERSE DIRECTION

O:000

3

Operator

Drive Actual Reverse

Status Display

0004

N9:0

7

Drive Logic Status

FAULTED

O:000

4

Operator

Drive Fault Status

Display

0005

N9:0

8

Drive Logic Status

AT SPEED

O:000

5

Operator

Drive At Speed

Status Display