Enerpac GT-Series User Manual

Page 7

7

7.0 TENSIONING AND DE-TENSIONING

WARNING: Never stand in-line with the bolt axis while

the system is pressurized. If the bolt should fail,

serious personal injury or death could result if loose or

broken parts become projectiles. All personnel must be aware

of this potential hazard at all times.

WARNING: Ensure that the maximum working pressure

and maximum stroke are not exceeded. Refer to the

specifi cations stamped on the tensioner body. Also see

Table 2 at the end of this document.

IMPORTANT: If the maximum stroke indicator appears at any

time during the following procedures, immediately STOP the

pump, tighten nut(s) at the tensioner(s) and release hydraulic

pressure. Then, turn down the threaded puller(s) to return the

piston(s) back into the tensioner(s) before continuing. Refer to

Section 4.1 for additional information.

IMPORTANT: If any leaks occur, immediately stop the pump and

open the pressure release (return-to-tank) valve. Be sure that

the oil pressure gauge indicates zero (0) psi/bar. Make repairs as

required before continuing with tensioning procedures.

Note: For improved illustration clarity, only one hydraulic hose is

shown connected to the tensioner in fi gures 7-11.

7.1 Tensioning Instructions - 100% Coverage

(tensioner installed on each stud)

IMPORTANT: Read precautions and instructions at beginning of

Section 7.0 before beginning the following steps. Also refer to

safety information contained in sections 2.1 and 2.2.

1. Ensure that the joint is correctly aligned.

2. Assemble the tensioner(s) to the stud(s) and connect

hydraulic hoses. Refer to sections 6.1 and 6.2 for additional

tensioner installation and hose connection instructions.

3. Determine the required hydraulic tensioning pressure. This

value must be calculated by a qualifi ed engineer with bolting

experience.

4. Operate the pump and pressurize the tensioners up to

approximately 1000 PSI [70 bar]. Check for oil leaks.

5. If no leaks are found, continue pressurizing the tensioners

to the calculated value determined in step 3. Continually

observe the tensioner stroke and hydraulic pressure at all

times during pressurization.

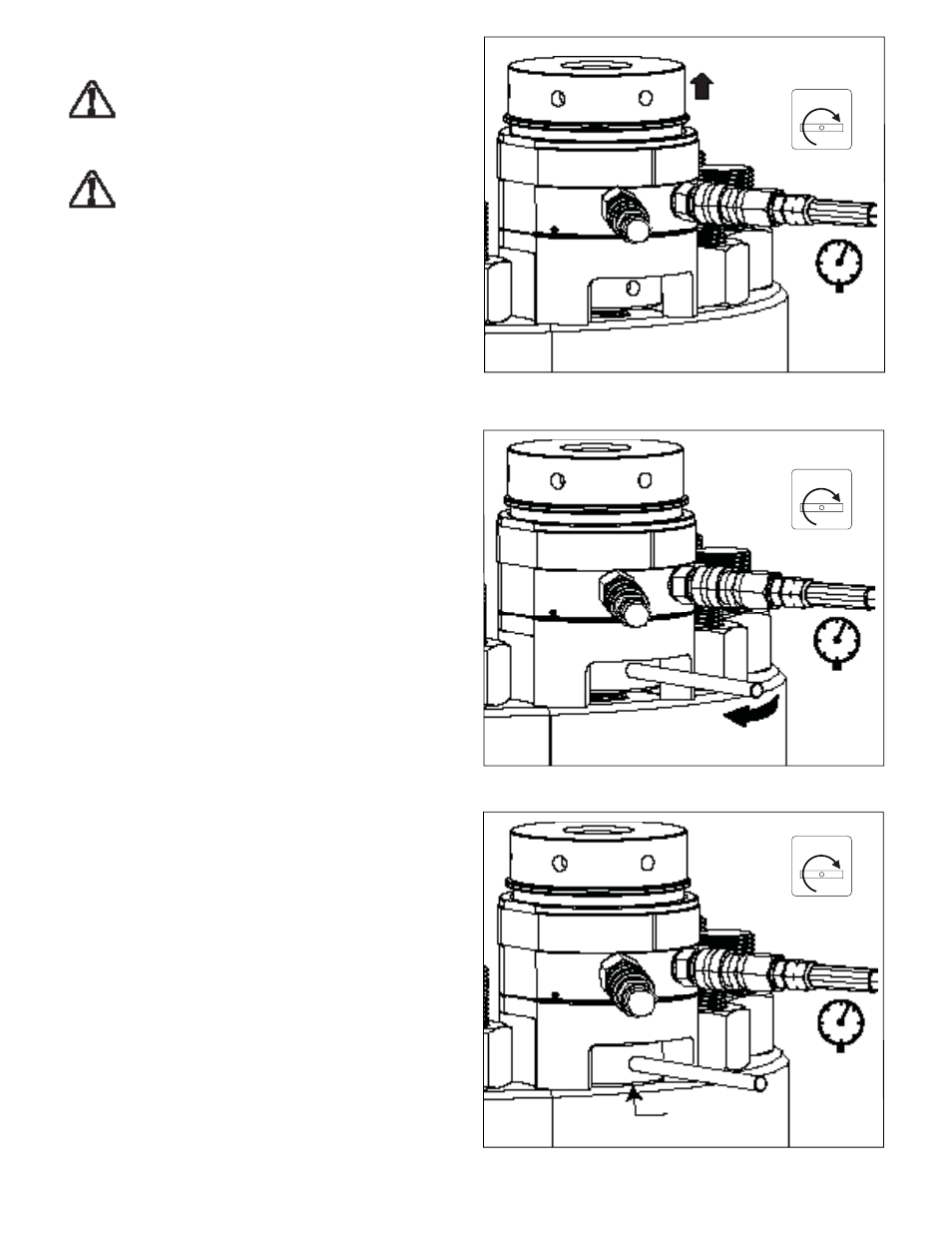

6. When the calculated hydraulic pressure is reached, stop

the pump. Recheck the oil pressure gauge after pump has

stopped. Be sure the pressure is stable (not increasing or

decreasing). Threads may be visible between the nut and the

joint surface at each tensioner. See Figure 7.

7.

While holding the pressure constant, use a tommy bar to turn

down the fi rst socket and nut by hand. Continue tightening

until the nut is fi rmly seated against the joint surface. See

fi gures 8 and 9.

8. Repeat step 7 for all remaining studs in the circuit.

9. Release the hydraulic pressure by SLOWLY opening the

pump pressure release (return to tank) valve. Verify that the

oil pressure gauge indicates zero (0) psi/bar. See Figure 10.

10. Check the piston stroke. If necessary, turn down the threaded

puller until the piston is fully retracted into the tensioner

body. See Figure 11.

11. Repeat steps 4 through 10 a second time.

12. Repeat steps 4 through 10 a third time.

Figure 7, Pressurizing the Tensioner

Figure 8, Turning Down the Socket and Nut

Figure 9, Socket and Nut Firm Against Joint

NO Threads

PRESSURE

RELEASE

CLOSED

PRESSURE

RELEASE

CLOSED

PRESSURE

RELEASE

CLOSED