Enerpac GT-Series User Manual

Page 10

10

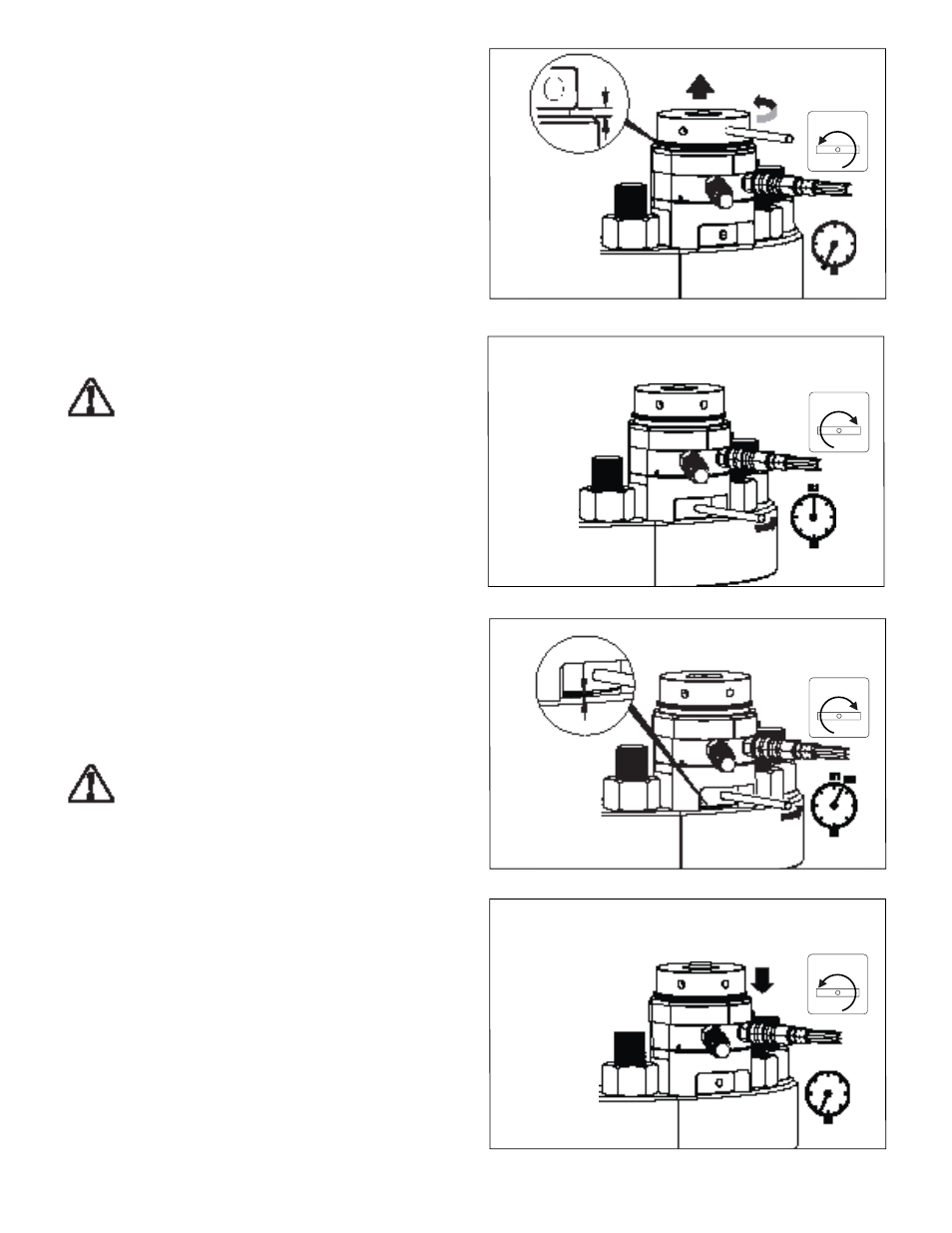

Figure 15, Turning Up the Threaded Puller

Figure 16, Determining the “Break Loose” Pressure

Figure 17, Turning Up the Nut

Figure 18, Pressure Released - Nut De-tensioned

7.3 De-tensioning Instructions - 100% Coverage

(tensioner installed on each stud)

IMPORTANT: Read precautions and instructions at beginning of

Section 7.0 before beginning the following steps. Also refer to

safety information contained in sections 2.1 and 2.2.

Note: For improved illustration clarity, only one hydraulic hose is

shown connected to the tensioner in fi gures 15-18.

1. Assemble the tensioner(s) to the stud(s) to be de-tensioned

and connect the hydraulic hoses. Refer to sections 6.1 and

6.2 for additional tensioner installation and hose connection

instructions.

2.

BEFORE applying any hydraulic pressure, turn up the threaded

puller at each stud as required, so that approximately a 3/16

inch [5 mm] gap appears between the fully retracted piston

and the threaded puller. See Figure 15.

3. Operate the pump to pressurize the tensioners up to

approximately 1000 PSI [70 bar]. Check for oil leaks.

WARNING: In the following de-tensioning steps, be

certain that the hydraulic pressure remains below the

maximum allowable hydraulic pressure of 21,750 psi

[1500 bar], and that the load applied does not exceed the tensile

strength of the stud.

4. If no leaks are found, continue operating the pump. Slowly

raise the pressure until the “break loose” hydraulic pressure

value is reached. This is the pressure at which a nut on one

of the tensioners just begins to loosen and can be turned by

hand with the tommy bar. Record this pressure for reference.

See Figure 16.

5. Increase the hydraulic pressure approximately 5 percent

above the “break loose” pressure recorded in step 4. Then,

stop the pump.

6.

While holding the pressure constant, turn up (loosen) the nut

at the fi rst tensioner, so that there is approximately a 1/8 inch

[3-4 mm] gap between the nut and the joint surface. See

Figure 17.

Note: Dimension of gap in step 6 must not exceed the dimension

of gap in step 2.

7. Repeat step 6 at all remaining studs.

CAUTION: If nuts are diffi cult to turn, hydraulic pressure

may be increased in additional 5 percent increments.

However, NEVER raise hydraulic pressure above 21,750

psi [1500 bar]. Ensure that the load applied does not exceed the

tensile strength of the stud.

8. Release the hydraulic pressure by SLOWLY opening the

pump pressure release (return to tank) valve. Verify that the

oil pressure gauge indicates zero (0) psi/bar. See Figure 18.

The studs are now fully de-tensioned.

9. Turn down the threaded pullers until the pistons are fully

retracted. Disconnect hydraulic hoses and install a dust

cap (not shown) over each disconnected coupler. Remove

tensioners from the studs.

3/16 inch [5mm]

Note: Try to turn up the

nut while slowly raising the

hydraulic pressure. When

the nut just begins to turn,

the “break loose” pressure

(B1) has been reached.

B1= Break Loose Pressure

1/8 inch

[3-4mm]

B2= Break Loose Pressure (B1) + 5%

PRESSURE

RELEASE

OPEN

PRESSURE

RELEASE

CLOSED

PRESSURE

RELEASE

CLOSED

PRESSURE

RELEASE

OPEN