Enerpac GT-Series User Manual

Page 3

3

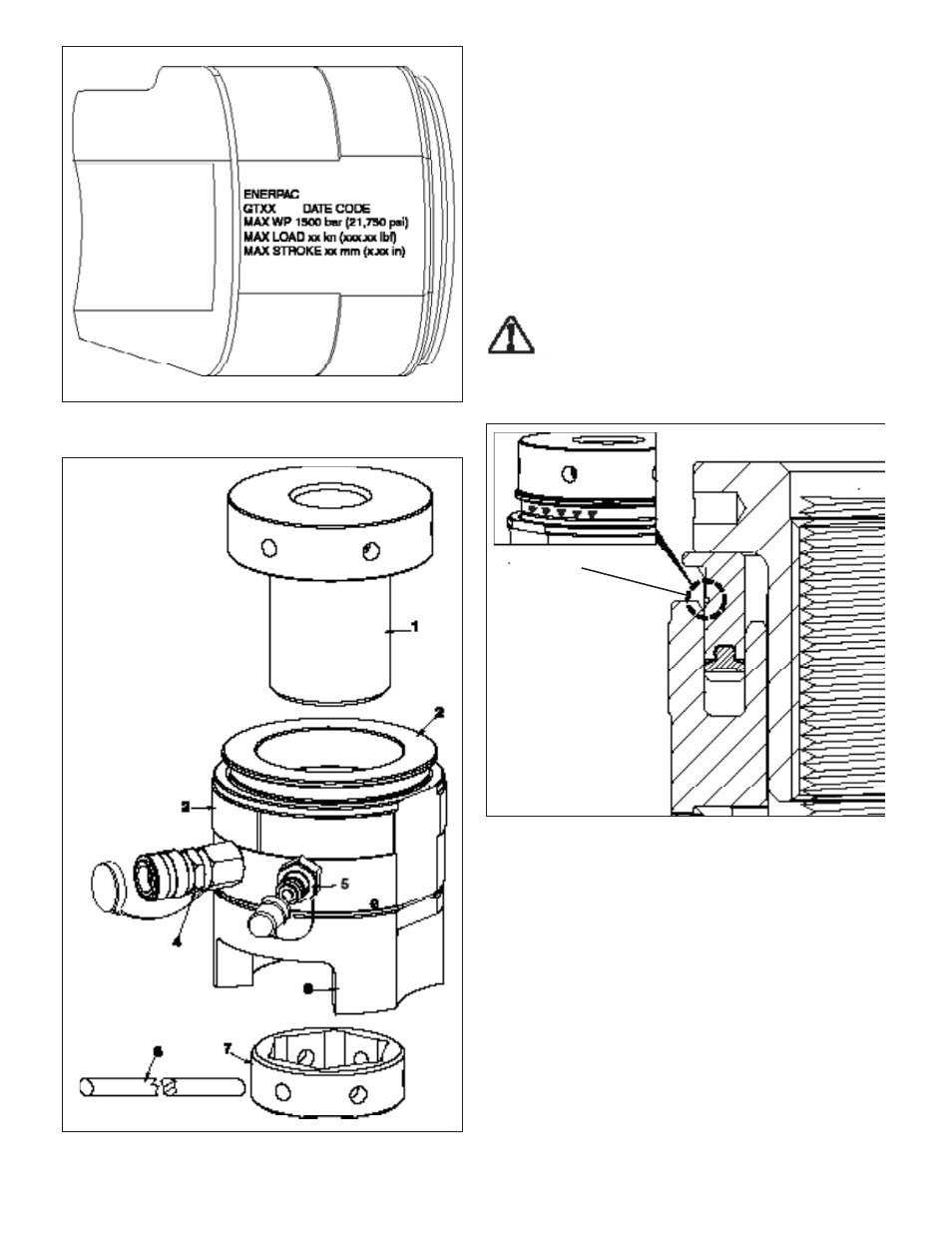

4.1 Maximum Stroke Indicator

Maximum allowable tensioner stroke is visually indicated by a

yellow painted groove located on the piston’s circumference.

Continually watch for the maximum stroke indicator during

tensioning procedures. Stop pressurizing the system immediately

if the indicator becomes visible.

If during any tensioning procedure, the maximum stroke indicator

appears before the desired hydraulic pressure is reached: STOP

the pump, tighten nut(s) at the tensioner(s) and release hydraulic

pressure. Then, turn down the threaded puller(s) to return the

piston(s) back into the tensioner(s).

To ensure proper tensioning, always repeat the tensioning stage

(start over) if the maximum stroke indicator appears before the

desired hydraulic pressure is reached.

WARNING: Continuing to pressurize the system after

the maximum stroke indicator becomes visible may

result in high pressure hydraulic oil leakage. Serious

personal injury could result if a stream of pressurized hydraulic

oil penetrates the skin. Damage to tensioner components and

joint may also occur if maximum stroke is exceeded.

Maximum

Stroke

Indicator

(Yellow Groove)

Figure 3, Maximum Stroke Indicator

5.0 SETTING UP

5.1 Hydraulic Oil

Oil requirements will vary, depending on pump model and type.

Refer to your pump instruction manual for oil specifi cations.

Failure to use genuine Enerpac hydraulic oil may void warranty.

5.2 Hoses and Fittings

All hydraulic hoses and fi ttings used in the circuit must be rated

at or above the maximum working pressure of the tensioner -

1500 bar [21,750 psi].

To ensure safe and reliable operation, use of Enerpac approved

high pressure hoses is strongly recommended. Refer to the

Enerpac Bolting Solutions Catalog for a complete list of available

hoses, fi ttings and related accessories.

Figure 2, Tensioner Major Components

Key:

1 - Threaded Puller

2 - Piston

3 - Body

4 - Coupler, Female

5 - Coupler, Male

6 - Bridge

7 - Socket

8 - Tommy Bar

Figure 1, Tensioner Data

Note: The tensioner

“load cell” includes

items 2, 3, 4 and 5

(assembled).