Enerpac GT-Series User Manual

Page 2

2

2.2 Hydraulic Tensioner Safety Precautions

DANGER: Failure to observe the following precautions

may result in serious personal injury or death.

WARNING: Hydraulic tensioners must be installed,

operated and maintained only by trained and skilled

personnel familiar with the safe operation of high

pressure tensioning devices and related equipment. All

calculations must be performed by a qualifi ed engineer with

appropriate training and bolting experience.

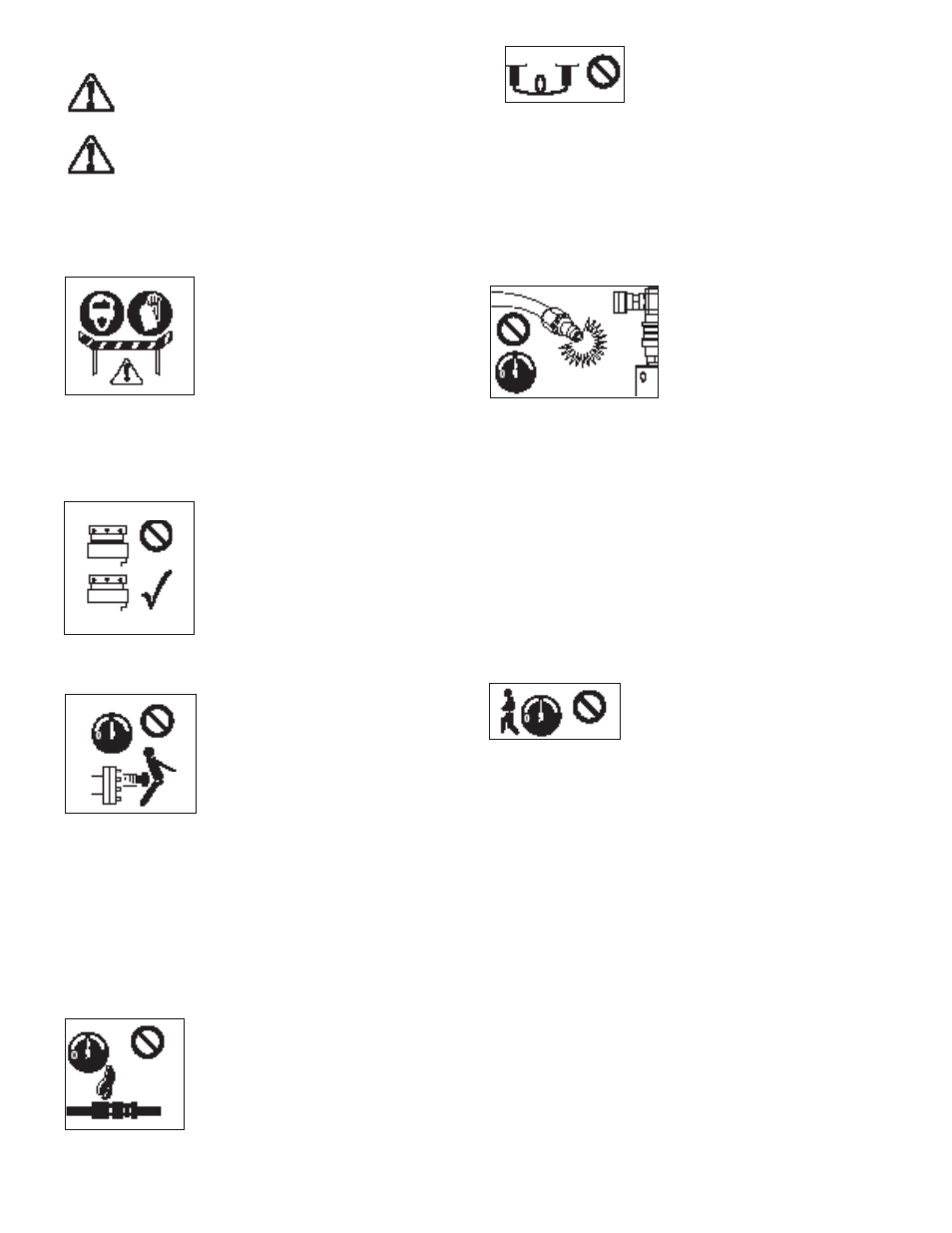

Always wear eye protection, gloves and boots when working

near a pressurized hydraulic system.

When working on site, the work

area should be roped-off and all non

essential personnel not involved with

the site operation should be kept clear

of the working area.

Before starting tensioning procedures,

be sure that all personnel are aware

that pressurization of high pressure

hydraulic equipment is about to occur.

Never exceed the maximum working pressure of the hydraulic

tensioner (1500 bar or 21,750 psi unless otherwise specifi ed).

Maximum working pressure is stamped on the tensioner body.

• Do not exceed the maximum allowable

piston movement (stroke) of the

hydraulic tensioner. An indicator will

appear when the tensioner is near

maximum extension. Refer to the

maximum stroke dimension stamped

on the tensioner body.

Never stand in-line with the bolt axis while tensioning or de-

tensioning is in progress. If the bolt should fail, serious personal

injury or death could result if loose or

broken parts become projectiles. All

personnel must be aware of this potential

hazard at all times.

Allow personnel to be near pressurized

hydraulic tensioners only when

absolutely necessary and only when the

pressure is steady. Continually observe

the pump pressure gauge.

Check that the threaded puller portion of the tensioner is fully

screwed onto the stud, and that the thread engagement is

suffi cient. Refer to the stud extension requirements diagram

(Figure 5) later in this document.

High pressure hydraulic equipment can be very dangerous if

misused. Keep away from oil leakages at high pressure. Liquid

escaping from highly pressurized equipment has suffi cient

power to penetrate the skin, which can cause blood poisoning.

In the case of such an accident, seek IMMEDIATE medical

attention.

Never attempt to repair leaks while the

system is pressurized. Be sure system

pressure gauge indicates zero (0) psi/bar

before making repairs.

Never attempt to disconnect a hydraulic

coupler while it is under pressure.

• Do not move or lift the hydraulic tensioners

using the hydraulic hoses and fi ttings.

•

•

•

•

•

•

•

•

•

•

Hoses should not be twisted or bent

too sharply. The bend radius should

not be less than the manufacturer’s

specifi ed minimum bend radius for

your hose type.

Before pressurizing the system, carefully inspect all hydraulic

hose assemblies. Replace any damaged, crushed or kinked

hoses immediately.

Before pressurizing the system, be sure that all hydraulic hoses

are connected. Each male coupler must be connected to a

corresponding female coupler. Verify that each coupler is fully

engaged and securely locked into position by physically pulling

on the connection.

Never pressurize the back of a

disconnected male coupler. Male

couplers cannot withstand high

pressures when disconnected.

Serious personal injury could

result if the coupler fails while

it is disconnected and under

pressure.

Only the female coupler on the LAST tensioner in the circuit

can remain uncoupled. All other couplers must be connected.

Check that the bolt material is capable of taking the initial load

to be applied. Hydraulic tensioners are powerful tools and are

capable of yielding or breaking studs/bolts if tensile/yield

properties are not suffi cient to support the load applied.

Use caution when pressurizing a system. Pressure can rise

faster than anticipated. Continuously monitor the pressure

gauge during pressurization. Be prepared to stop the pump

immediately at any time.

When using a powered pump, be sure that the relief valve is

adjusted to the appropriate setting, so the hydraulic tensioners

do not apply excessive force for the application. The hydraulic

working pressure must not exceed 1500 bar [21,750 psi].

Never leave a pressurized system

unattended. If you must leave the area,

stop the pump, fully open the pressure

release valve and ensure that hydraulic

pressure gauge indicates zero (0) psi/

bar.

Any maintenance or repairs to the hydraulic tensioners, the

pump or related components must be performed with the

equipment in the unpressurized state (0 psi/bar).

3.0 SPECIFICATIONS

Major tensioner specifi

cations, such as maximum working

pressure, maximum load and maximum stroke are

stamped into the side of the hydraulic tensioner body. See

Figure 1. Be aware of these specifi cations during installation and

set-up.

IMPORTANT: The required working pressure for the tensioning

application will typically be less than the maximum working

pressure stamped on the tensioner body.

Refer to Table 2 (located near the end of this document) for

additional GT Series tensioner specifi cations.

4.0 FEATURES AND COMPONENTS

Refer to Figure 2 for a diagram of GT Series tensioner major

components.

•

•

•

•

•

•

•

•

•

•