Enerpac GT-Series User Manual

Page 11

11

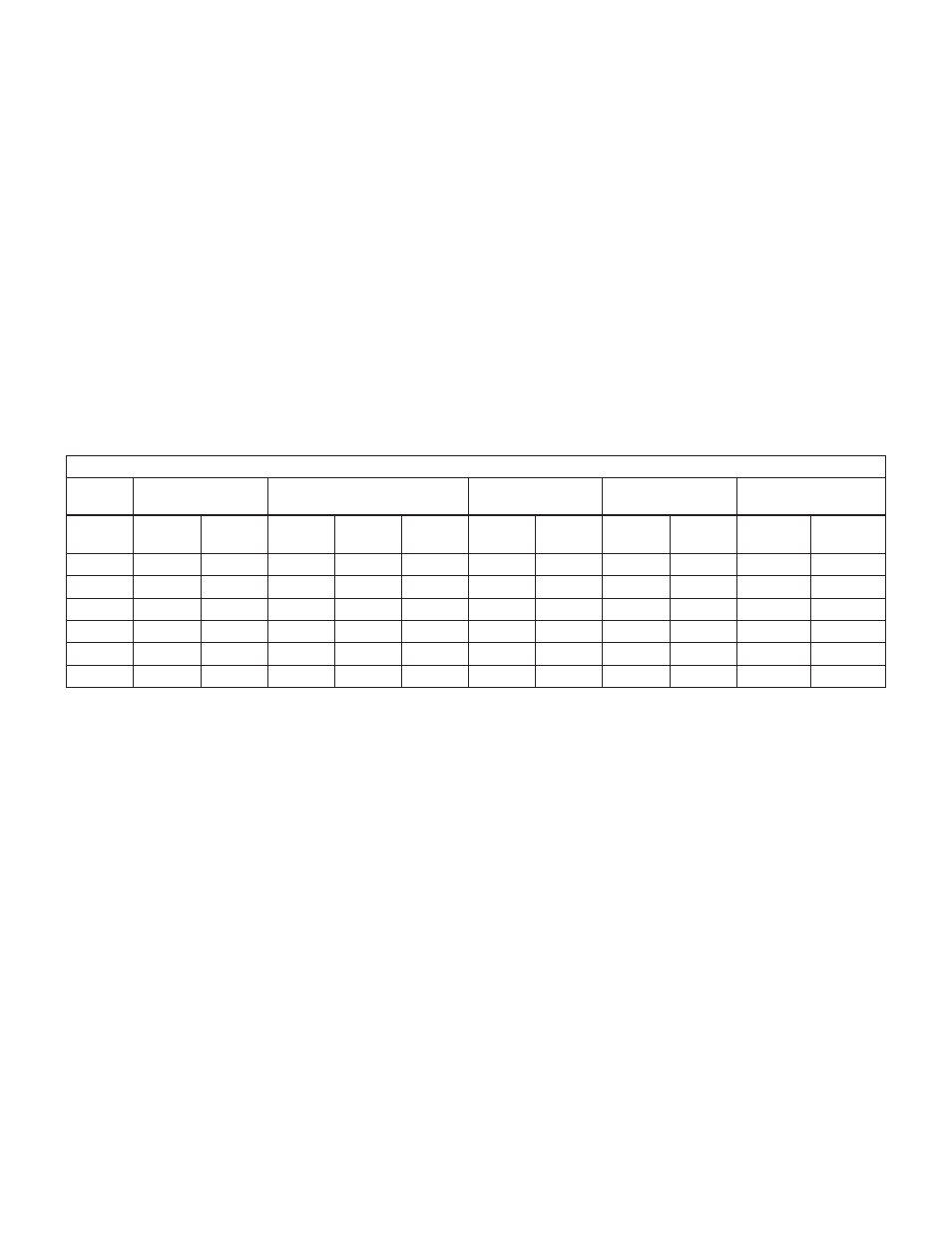

Table 2, Technical Data, Enerpac GT Series Hydraulic Tensioners

Series

Maximum

Pressure

Max Load

Hydraulic

Effective Area

Maximum Stroke

Weight

psi

bar

lbf

klbf

kN

inch

2

mm

2

inch

mm

lbs.

Kg

GT1

21,750

1500

50,414

50,4

224

2.32

1496

0.39

10,0

9.7-11.1

4,2-4,8

GT2

21,750

1500

90,256

90,2

402

4.15

2677

0.39

10,0

14.5-23.1

6,3-7,0

GT3

21,750

1500

172,847

172,8

769

7.95

5127

0.39

10,0

26.3-29.9

11,4-13,0

GT4

21,750

1500

329,780

329,7

1467

15.16

9782

0.39

10,0

47.2-53.4

20,5-23,2

GT5

21,750

1500

508,374

508,3

2262

23.37

15079

0.39

10,0

73.9-84.5

32,1-36,7

GT6

21,750

1500

639,598

639,5

2846

29.41

18972

0.39

10,0

103.1-115.7

44,8-50,3

7.4 De-tensioning Instructions - 50% Coverage

(tensioner installed on every other stud)

IMPORTANT: Read precautions and instructions at beginning of

Section 7.0 before beginning the following steps. Also refer to

safety information contained in sections 2.1 and 2.2.

1. Assemble the tensioner(s) to the fi rst 50% of stud(s) to be

de-tensioned and connect the hydraulic hoses. Refer to

sections 6.1 and 6.2 for additional tensioner installation and

hose connection instructions.

2. Follow steps 2 through 8 of Section 7.3 for the fi rst 50% of

studs.

3. Move the tensioners to the second 50% of studs.

4. Follow steps 2 through 9 of Section 7.3 for the remaining

50% of studs. Note that the “break loose” hydraulic pressure

for the second set of studs will likely be about the same or

slightly lower than that for the fi rst set.

8.0 STORAGE

The tensioner’s black oxide fi nish will help protect it from rust

and corrosion. However, for added protection, a light coating of

oil or rust inhibitor should be applied to all metal surfaces.

Cover the internal threads of the threaded puller with oil or a

suitable rust inhibitor.

Store the tensioner upright, with the piston fully retracted

inside the body.

Always keep dust caps installed on couplers when the tensioner

is not being used.

Wipe all hoses clean and apply a light coating of oil or suitable

rust inhibitor to all couplers.

•

•

•

•

•