Ab c, Installation – CHAMPION EEUCCW8 User Manual

Page 30

22

Installation

Sealing Section Joints

Installation

Machine section joints must be sealed using a food-grade

silicon sealant. Several tubes of approved sealant were

included in the installation hardware kit.

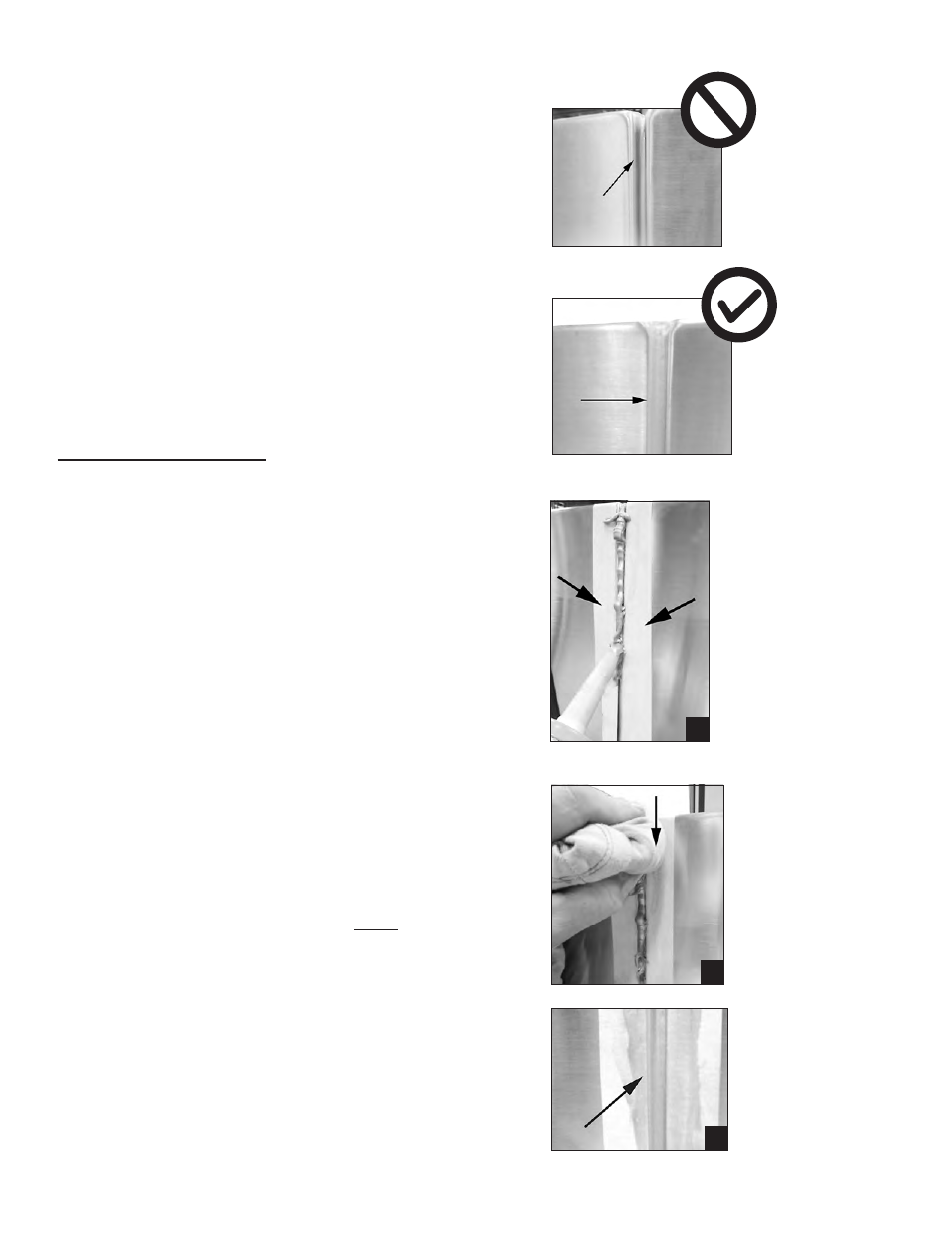

Study the photos on the right.

The top photo shows an incorrectly sealed joint. Note that the

joint seal has a valley indicating that insufficient sealant was

applied.

The bottom photo shows a correctly sealed joint. The joint seal

is filled and the transition between the sections is shallow.

To seal the section joints:

1. Make sure the machine sections are level, all utilities

and cross-connections are made and the sections are

bolted together.

2. Clean the joint with isopropyl alcohol to remove dust,

oil film, and other contaminants.

3. Mask the joint edges with a quick-release masking

tape.

4. Apply a 1/8" bead of food-grade silicon sealant

using moderate pressure on the caulking gun to

ensure the sealant fills the joint.

5. Wait 1 minute for the sealant surface to firm slightly

(but before a skin forms), then wipe the joint with a

clean damp cloth.

6. Wait 10-seconds after wiping the joint, then remove the

masking tape.

7. The joints can be cleaned and trimmed in about 1 hour.

A

B

C

Note:

If the sealant dries longer than 1 minute, do not try to wipe

the joint. Allow the sealant 30 minutes to dry, then cut the

sealant out of the joint and reseal the joint.