RADWAG MAX 60 Moisture Analyzer User Manual

Page 71

- 71 -

can be prepared for measurement otherwise than grinding, any possible

moisture content loss should be calculated.

Use of high-silica sand

Ensuring optimum substance drying requires that a sample has the largest

possible surface for moisture content vaporization. Test results of moisture

content in substance which surface has a form of a shell (e.g. glucose syrup) or

doughy (e.g. butter), can be much more reliable if a sample is mixed with a

dried high-silica sand (improvement of measurement accuracy and

repeatability).

When testing a substance by mixing it with high-silica sand it is recommended

to use a disposable drying pan with higher edges due to larger volume of a

sample to be tested).

Grease in a form of paste or melting substances

Such substance requires testing with use of a filter made of glass fiber, which

considerably increases active evaporation surface by separating the substance

between the fiber. Initial filter drying is necessary only in case of measurements

which require very high accuracy.

Liquid substances

It refers to liquid substances, which by creation of drops on their surface,

caused by surface tension, may render difficulties in drying process. In such

cases, it is proved to use a glass fiber filter to shorten measurement time. The

filter causes separating tested liquid around the fibers, and increasing active

evaporating surface. Initial filter drying is necessary only in case of

measurements which require very high accuracy.

Substances with structure of leather or temperature sensitive

In case of such substances it is proved to a glass fibre filter. While testing, a

substance is placed on a drying pan, and sample surface is covered with a

filter, which protects the sample from direct heat radiation. In such case, the

sample is heated by convection (which is milder than radiation).

Substances containing sugar

The surface of such substances often may caramelize during testing

procedure. Therefore, it is recommended to use thin layer of a sample, and

moderate drying temperature.

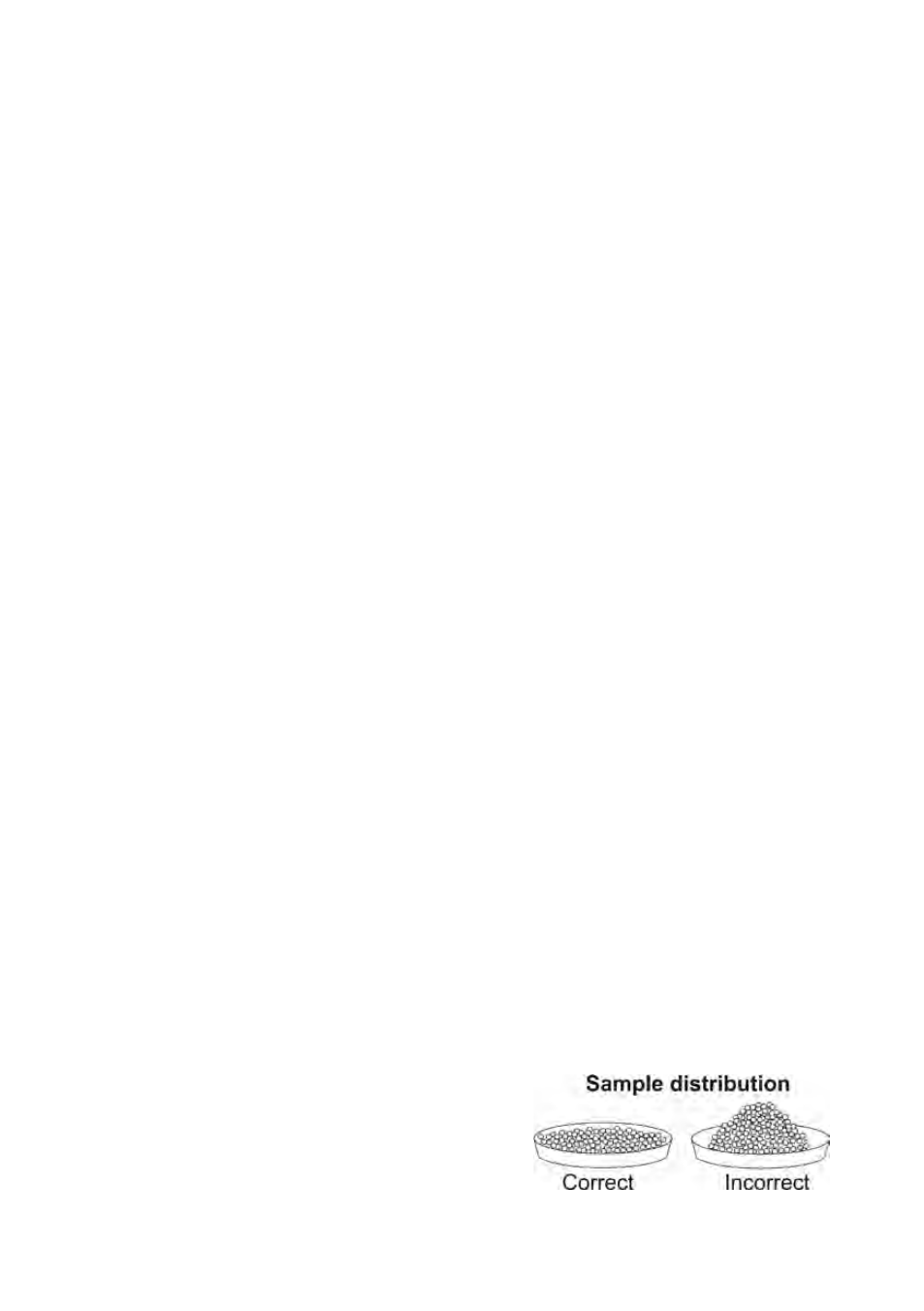

Sample distribution on drying pan:

Loose materials

Dried in their natural state, i.e. in their natural form or disintegrated. Sample

disintegration causes smaller dispersion

between the following measurements.

Sample mass should not be too high, and

the sample should be evenly spread on

whole surface of the drying pan.