Setting a corrective coefficient – RADWAG MAX 60 Moisture Analyzer User Manual

Page 63

- 63 -

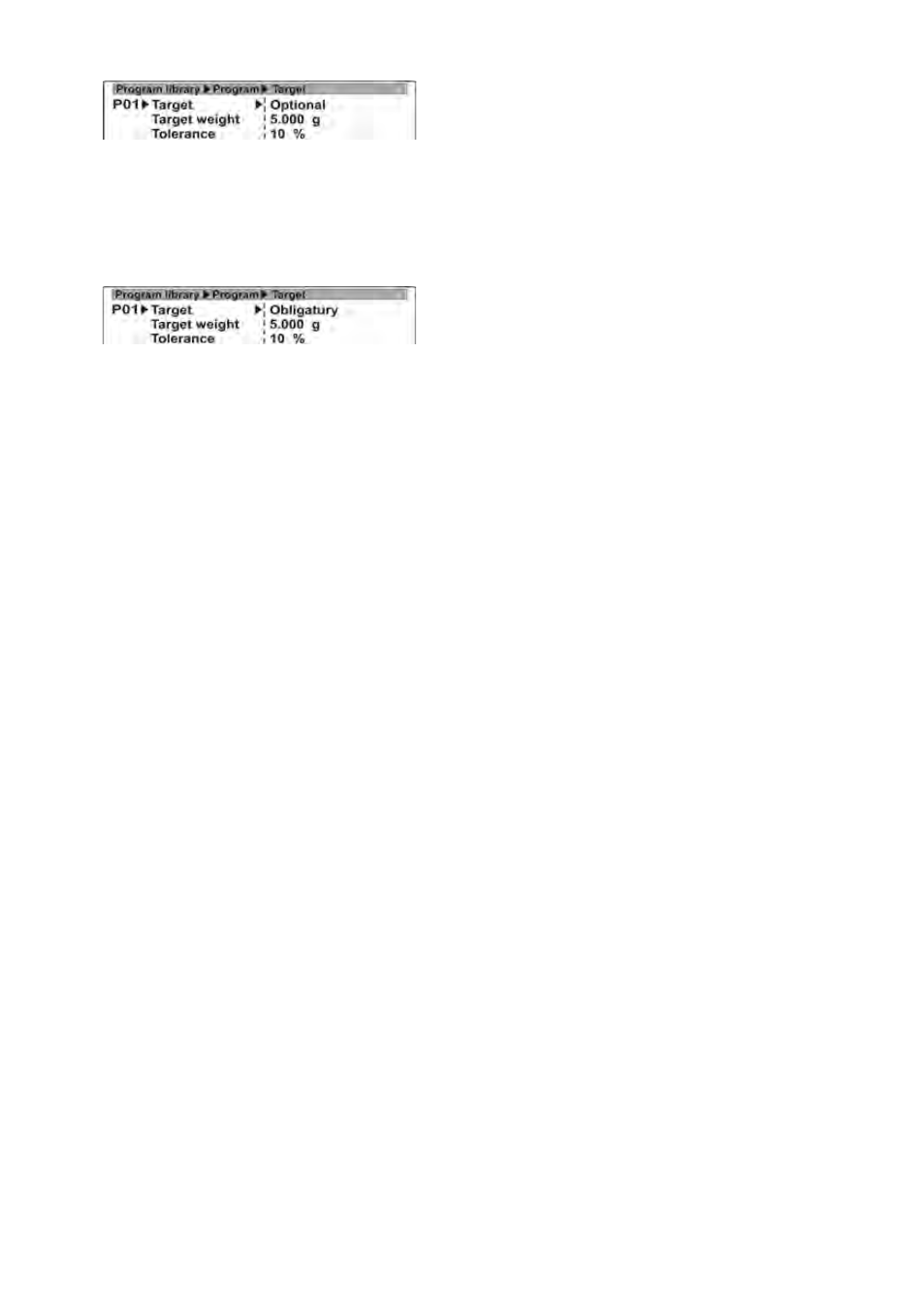

In case option Optional is enabled the

user has to enter required sample mass

and tolerance value for the material to be

weighed / dried.

If sample mass option is enabled, the moisture analyzer displays prompts for the

user on placing a required size of a sample to be tested on the drying pan. If a user

neds to dry a sample with different mass, then drying process can be started even if

the mass does not comply with set parameter criterion.

In case option Obligatory, is enabled the

user has to enter required sample mass

and tolerance value for the material to be

weighed / dried.

After selecting this option, the moisture analyzer displays prompts for the user on

placing a required size of a sample to be tested on the drying pan. In Mandatory

option the drying process will not start unless the mass of a sample to be tested

complies with the parameter settings.

10.9.

Setting a corrective coefficient

Coefficient correcting drying temperature

Materials of dark colours are affected by the phenomenon of heat absorption. In

such case the tested sample can be overheated, i.e. when drying a dark

coloured sample in a temperature 120

o

C, the sample may absorb heat and heat

up to approximately 135

o

C. Therefore, it is necessary to determine the

coefficient correcting the drying temperature. The process requires using a

control thermometer with a probe (available as accessories for the moisture

analyzer).

Means of determining the corrective coefficient:

1. Program all parameters of a drying process.

2. Spread evenly a sample to be tested on the drying pan and start drying

process.

3. On completion of the drying process note down the drying time

4. Prepare another sample of the same material and spread it evenly on

the drying pan. Prepare a thicker layer of the sample to be tested.

5. Insert the probe of the control thermometer into the tested sample,

press ON/OFF button on the control thermometer

6. Start drying process

7. Monitor the temperature values displayed on the moisture analzyer and

the control thermometer

8. After the time value specified for the first tested sample check both of

the temperature values.

9. Calculate the corrective coefficient using an equation:

T

measured

– T

set

--------------------------------------------------------

T

set