Non-standard printout templates, Inserting text into strings – RADWAG MAX 60 Moisture Analyzer User Manual

Page 39

- 39 -

8.6.2.

Non-standard printout templates

Principles of creating non-standard printout templates:

1.

Moisture analyzer MAX series enables creating up to 4 custom

printout templates;

2.

each template must have the string of text start and end specified,

e.g. Printout no. 1 Start – 1 and Printout no. 1 Stop – 40. In this

case the Printout no. 1 contains text strings from 1 to 40.

3.

Next insert the texts into the specified text strings, i.e. 1

÷ 40.

It is recommended to use an external computer keyboard

connected to moisture analyzer’s port. This means of text input is

much simpler and quicker.

4.

Non-standard printout templates may overlap each other, i.e.:

Printout 1 Start – 1

Printout 1 Stop – 40

Printout 2 Start – 20

Printout 2 Stop – 40

A non-standard printout can contain:

Variables dependent on user needs (mass, date, project no., temperature

of the drying chamber, etc.)

Texts inserted in moisture analyzer’s user menu

A custom non-standard printout template can contain up to 640 characters

inserted in 80 text strings, 8 character each. (starting with parameter String 1

to String 80). A balance user can create up to 4 non-standard printout

templates.

8.6.3.

Inserting text into strings

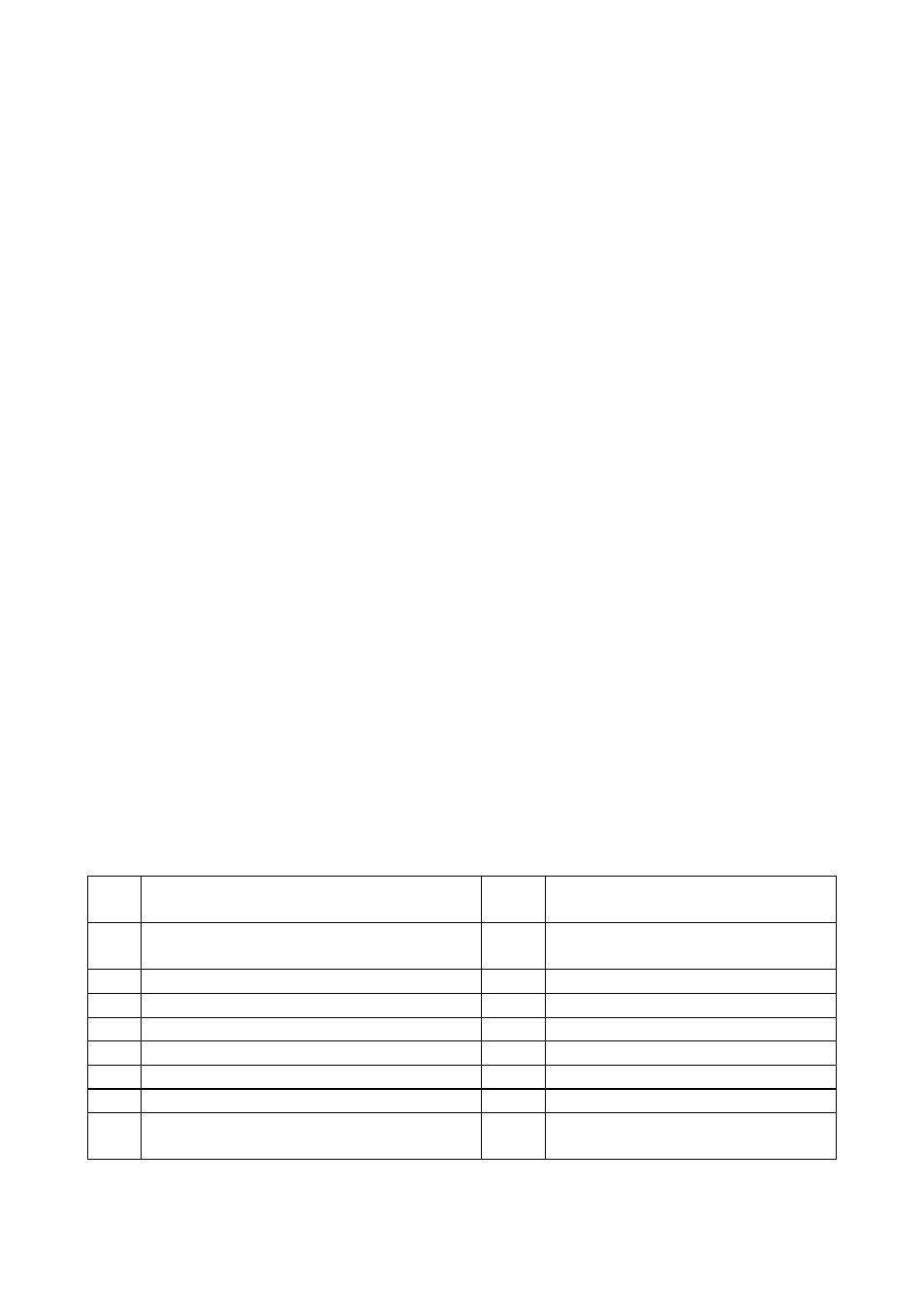

Variables in printouts

%%

Printout of a single character “%”

%K

Type of last completed

adjustment process

%N Current net mass in basic measuring

unit

%I

Deviation in last completed

adjustment process

%d Current date

%1

Code 1

%t

Current time

%2

Code 2

%i

Balance factory no.

%3

Code 3

%r

Software no.

%4

Code 4

%P Project no.

%5

Code 5

%U User no.

%6

Code 6

%k

Date and time of last completed

adjustment process