Drying test – RADWAG MAX 60 Moisture Analyzer User Manual

Page 29

- 29 -

P1 05 Report printout :

1 : YES – report is printed

P1 05 Report printout:

0 : NO – report is not printed

Remember that on enabling report printout (set to 1), the report is generated

and sent automatically.

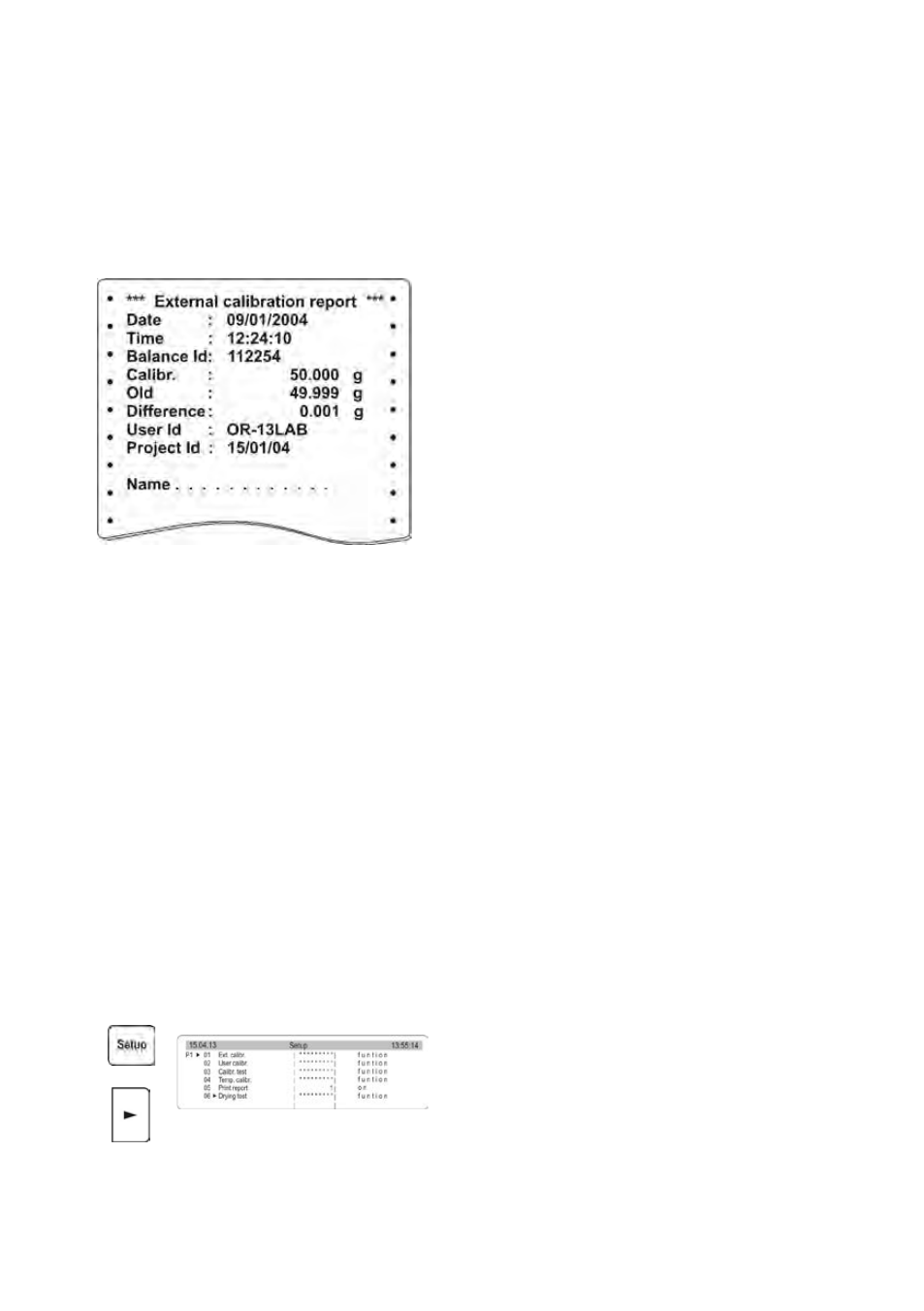

An example of a printout of a report from adjustment process:

The printout content depends on

parameters set in group P2 GLP (see point

8.2 of this user manual). Variables that are

printed have an attribute set to 1: yes.

Apart from the content set in this menu

group, a report contains the following data:

mass of an adjustment weight stored in

moisture analyzer memory from last

completed adjustment process (described as

Curr:), mass of an adjustment weight

determined in current adjustment process

(described as Adj: (or Cal) and a deviation

from adjustment process (described as

Dev:), i.e. the difference between the two

mass values.

8.1.6.

Drying test

Parameter

indications as recorded by the moisture analyzer’s internal thermometer.

The testing procedure is carried out using a dedicated set (a thermometer with a

holder) that is available as additional equipment of a moisture analyzer MAX

series. (It is the same set that is used for carrying out temperature adjustment

process). Means of assembling the set is described in the chapter on

temperature adjustment of this user manual.

Enabling the testing procedure requires assembling the control set inside the

moisture analyzer’s drying chamber, and entering a menu group

in instrument’s parameters. Start the process by following below specified

instructions.

Remember to assembly the control thermometer set before starting the testing

procedure and then close the drying chamber lid.

Enter menu group P1 Adjustment.

Set the marker next to a parameter 06

Drying test