Control start procedure – RADWAG WLY Scales User Manual

Page 132

132

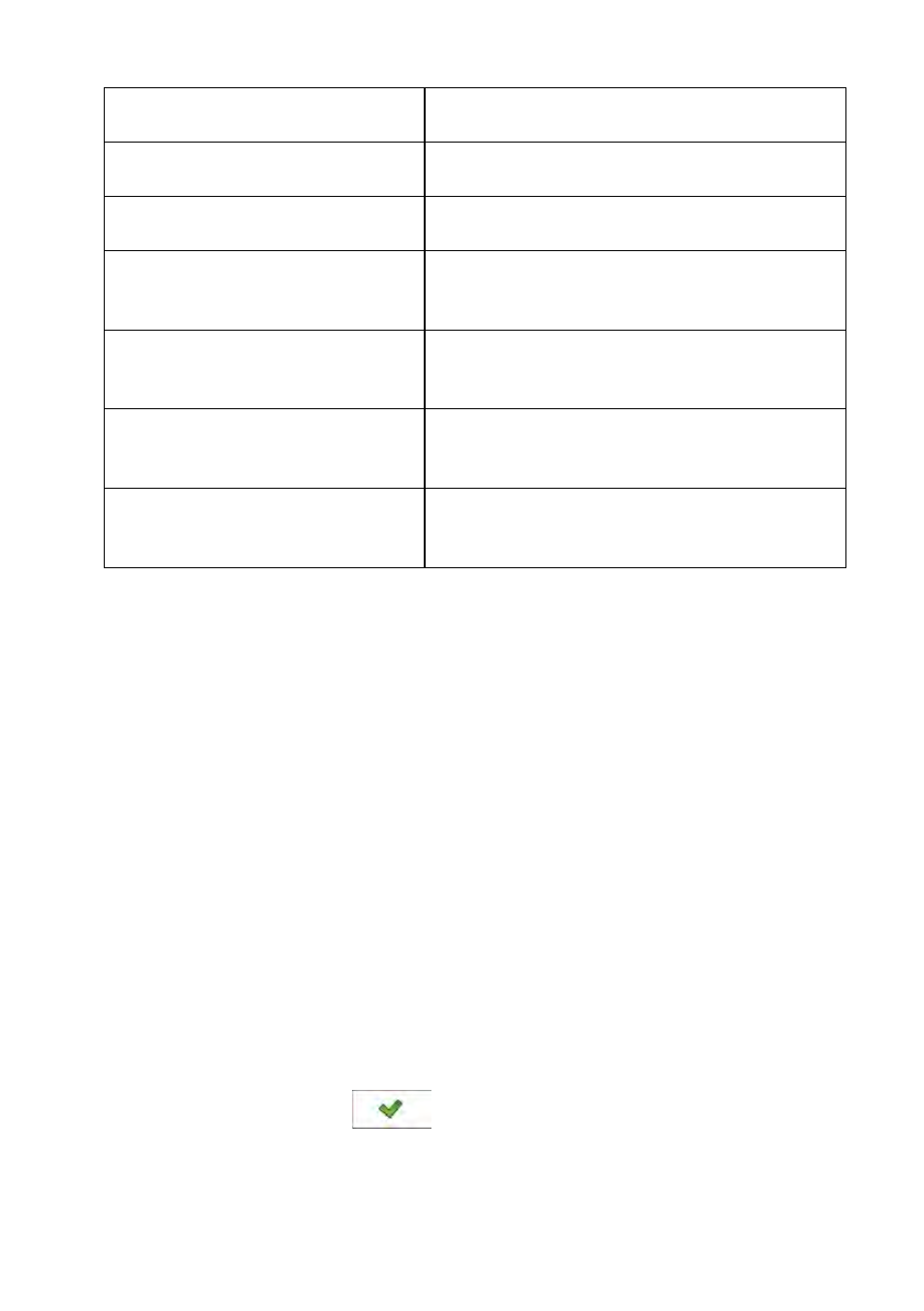

Quantity of disqualifying

samples [Qn – T]

Number of recorded negative errors -T in

a tested sample that disqualifies a control

Quantity of disqualifying

samples [Qn + T]

Number of recorded positive errors +T in

a tested sample that disqualifies a control

Average limit value

Mode for calculating the average limit value

(constant or automatic)

Average limit value [ - ]

Average limit value (negative) for a tested

sample (refers to averge limit value as a

“constant”)

Average limit value [ + ]

Average limit value (positive) for a tested

sample (refers to averge limit value as a

“constant”)

Factor value [- Wk]

Standard deviation multiplier for the average

limit value (negative) determined in the

automatic mode

Factor value [+ Wk]

Standard deviation multiplier for the average

limit value (postive) determined in the

automatic mode

30.5. Control start procedure

To start testing:

•

An operator needs to be logged on with the authorization access level

high enough to perform testing.

Caution:

The logging on procedure is described in ch. 11. The procedure

of outlining the authorization level is described in ch. 19 of this manual.

•

Select a product to be tested with correctly determined data for the

control process,

•

Enter to scale memory general parameters on control mode (in

accordance with ch. 30.2 and 30.3 of the manual),

•

Remove load fro mthe weighing pan,

•

Press function hot-key

(control start) located in the bottom bar

of the settings window, which opens an information window on entered

data: