RADWAG WLY Scales User Manual

Page 115

115

5. [TI] Delay

[3s] Close

valve „Flour ”

Pending for closing the main valve of the

container “Flour”

6. [O] Outputs

Output 11 – „1” Output 11 takes high status („1”) – signal

confirming carrying out the dosing making

process on the weighing platform no. 1 is

lit up

7. [F] Set flags

Signal flag 1 –

„1”

Setting the characteristic point of the

process, which is a condition for carrying

out part of the process on the second

weighing platform

Dosing on the first weighing platform is carried out in two-steps, as for

ingredient „Flour” the outputs are set for two-step dosing – see Products

database.

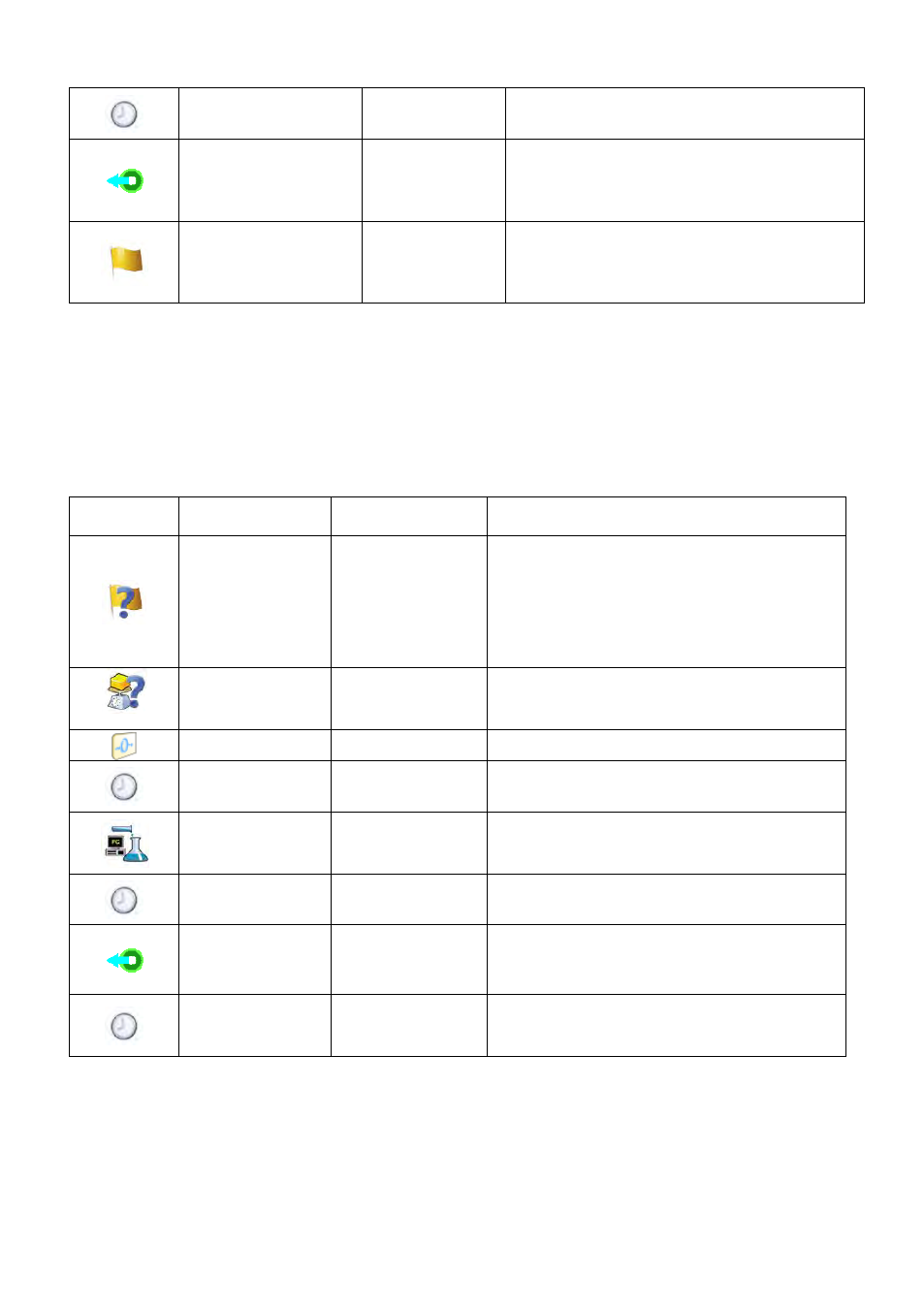

Platform 2

Icon

Step

Value

Description

1. [CF] Flags

condition

Signal flag 1 –

„1”

Checking condition, whether signal flag 1

is set to value “1” – i.e. checking whether

desired part of the process has been

already realized on the weighing platform

no. 1. If Yes, then dosing process on the

weighing platform no. 2 shall start.

2. [CM] Weight

condition

Gross<0.1 kg

Condition checking, unless the weighing

platform is loaded with a mass exceeding

100 g

3. [Z] Zero

Zero

Zeroing the weighing platform no. 2

4. [TI] Delay

[5s] Open valve

Water

Pending for opening main valve of the

container with “Water”

5. [DA]

Automatic

batching

2,2 kg [Water]

Automatic dosing of ingredient “Water” to

obtain 2,2 kg mass in single-step dosing

mode – Output 6 controls the dosing valve

6. [TI] Delay

[5s] Close valve

Water

Pending for closing the main valve of the

container “Water”

7. [O] Outputs

Output 12 – „1”

Output 12 takes high status (“1”) – signal

confirming carrying out the dosing process

on the weighing platform no. 2 is lit up

8. [TI] Delay

[5s] Dosing

process

completed

Displaying a text message on the terminal

confirming completion of dosing process.

Additionally, in automatic dosing process, additional setting of dosing outputs

for dosed ingredients have to be made – see Products database settings.