IAI America RCP2W-RA10C User Manual

Page 73

67

10. Maintenance

10.4 Applying Grease to the Ball Screw and Rod Slide Surface

10.4.1

Grease for Ball Screw

The dedicated grease specified below has been applied to the ball screw before the shipment.

Kyodo Yushi

Multemp LRL3

The following grease is applied to RCP2-RA8C, RA8R, RA10C and RCP2W-RA10C only.

Kyodo Yushi

Maltemp PS No.2

When maintaining your actuator, use a lithium grease spray. Keep the spraying time to within 1 second per

spray.

WAKO CHEMICAL, LTD.

Spray Grease No.A161 or

equivalent

There is AQ Collar attached on RCP2-RA8C/RA8R, RCP2-RA10C and RCP2W-RA10C.

However, to keep a stable condition for a long term, it is recommended to have grease-ups frequently in the

regular maintenance works.

Warning: Warning: Never use any fluorine-based grease. It will cause a chemical reaction when

mixed with a lithium-based grease and may cause damage to the actuator.

Keep the spraying time to within 1 second. Do not spray grease continuously for more

than 1 second or repeat spraying twice or more. Doing so may cause problems.

10.4.2

How to Apply Grease (Keep the spraying time to within 1 second per spray.)

Applicable Units : RCP2-RA3C, RA4C, RA6C, RA8C, RA8R, RA10C, RGS4C, RGS6C, RGD3C, RGD4C,

RGD6C, RCP2W-RA4C, RA6C, RCP2W-RA10C

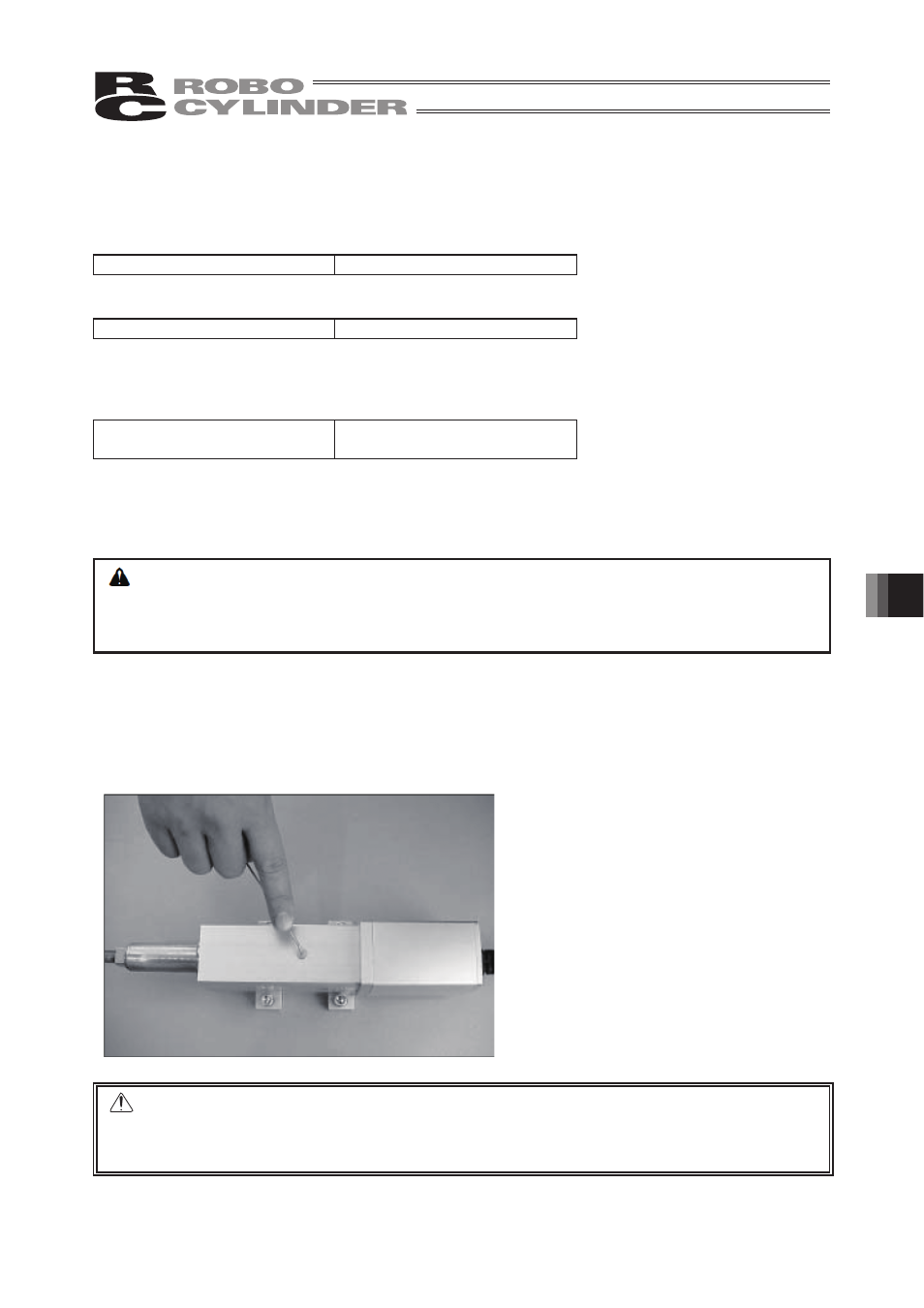

[1]

Remove the thin head screw at the

position shown in the photograph on

the left.

Caution: In case the grease got into your eye, immediately go to see the doctor to get an appropriate

care.

After finishing the grease supply work, wash your hands carefully with water and soap to

rinse the grease off.