IAI America RCP2W-RA10C User Manual

Page 61

55

7. Cautions in Operation

2) Condition 2

The continuous operation torque of the cycle should be 2.08N•m or less.

Calculate the torque for continuous operation.

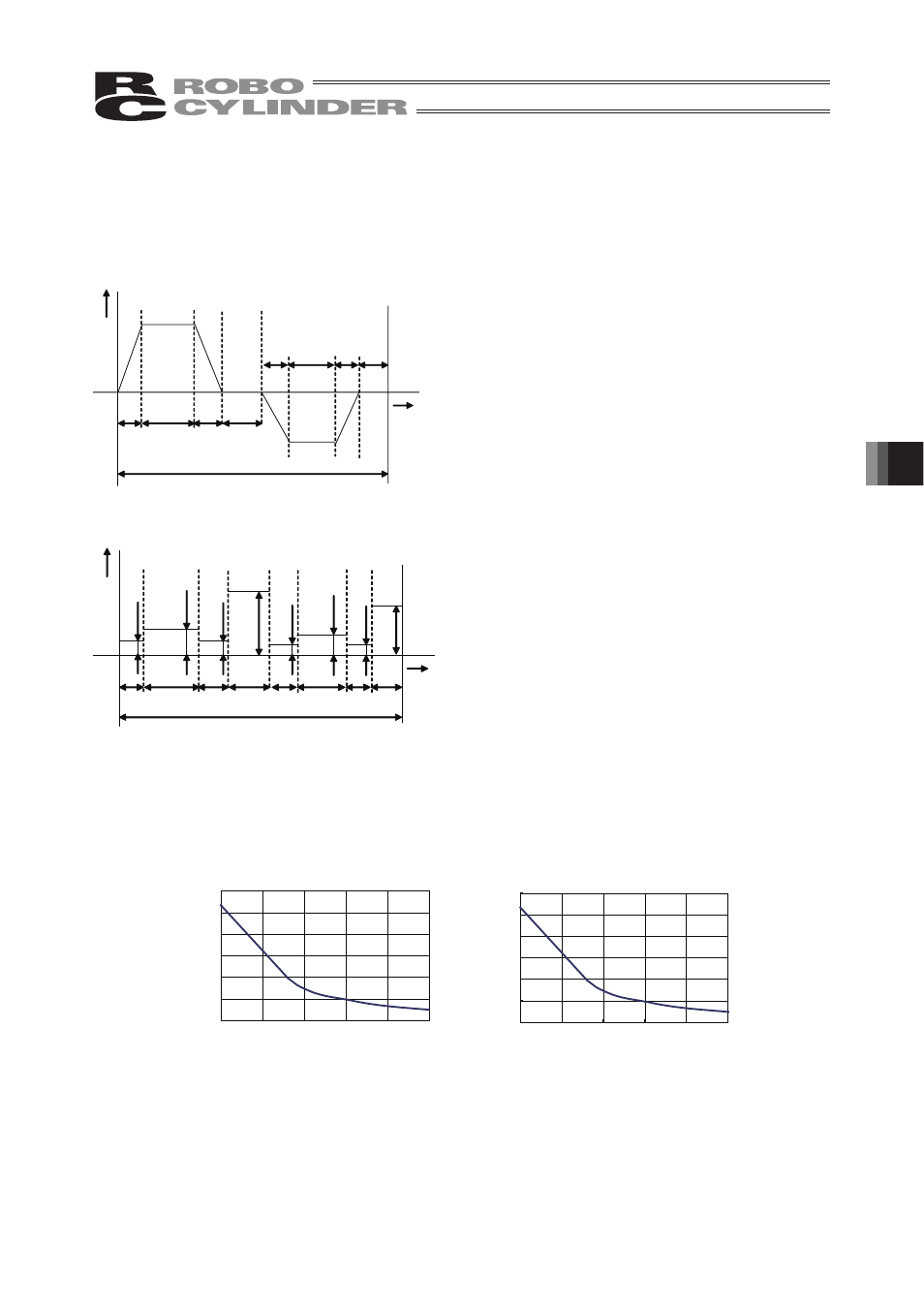

In Graph 2, shows the speed change of the actuator in continuous operation on the time-basis. In

Graph 3, shows the torque change in time-basis.

t

tw

t2a

f

2

t

d

2

t

to

t1a

f

1

t

d

1

t

V

T

Graph 2: Actuator Speed Change on Time-basis

Tw

T2f

T2d

T2a

T1d

T1a

tw

t2a

t2d

t2f

to

t1a

t

t1d

t1f

F

T

To

T1f

Graph 3: Torque Change on Time-basis

Read the motor torques T1a, T1f, T1d, T2a, T2f, T2d except for To and Tw shown in Graph 3 from

Graph 4. For the motor torques required for acceleration/deceleration, read the motor torque of

reached speed (constant speed) / 2 for the motor torque required for acceleration/deceleration.

0

0.5

1

1.5

2

2.5

3

0

30

60

90

120

150

0

0.5

1

1.5

2

2.5

3

0

60

120

180

240

300

Graph 4: Speed and Motor Torque

Speed [mm/sec]

Speed [mm/sec]

Motor Torque [N•m]

Motor Torque [N•m]

Lead 5

Lead 10

t

: Operation time in 1 cycle [s]

t1a : Acceleration time 1

t1f

: Constant speed operation time 1

t1d : Deceleration time 1

to

: Pressing operation time

*within the range of Condition 1

t2a : Acceleration time 2

t2f

: Constant speed operation time 2

t2d : Deceleration time 2

tw

: Standby time

T1a : Motor torque required for acceleration 1

T1f : Motor torque required for constant operation1

T1d : Motor torque required for deceleration 1

To

: Motor torque required for pressing operation

T2a : Motor torque required for acceleration 2

T2f : Motor torque required for constant operation 2

T2d : Motor torque required for deceleration 2

Tw : Motor torque required for standby