R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 95

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

95/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Rotation resistant ropes have more outer strands than standard ropes. Outer strands have left hand lay,

while inner strands are in right hand lay.

5.30.2 Service

• Inspect the rope. Regular rope inspection and maintenance shall be carried out according to the

guideline instructions below and according to international standard ISO 4309:2004.

• Lubricate the rope with suitable lubrication. Lubricant for wire rope shall be water resistant, non-

adhesive, transparent thin oil, which is able to penetrate in the rope.

!

The rope shall be changed before the limits have been reached. Change the rope if there is a

risk that limits are reached before the next examination.

5.30.2.1 Periodical

examinations

Visual deformations and damages in the rope shall be inspected daily by the user. Wire ropes shall be

inspected by authorized service personnel at least every 12 months or 10% SWP.

The inspection intervals should be shortened when:

-

The hoist is used in heavy duty or process use (e.g. duty class M6 or higher, papermill cranes etc.)

-

The hoist is used under harsh conditions (e.g. extreme temperatures, excessive dirt/dust or outdoors)

-

Previous examinations indicated a high rate of wear.

In case of doubts, please contact the manufacturer for advice.

5.30.2.2 Discard

criterias

Maximum number of broken wires in outer strands

Examination of the broken wires shall be made at least in the rope area, which has the most bendings

over the rope sheaves during normal operation, and at the rope end near the wedge housing. Before the

examination of broken wires, the examination areas shall be carefully cleaned. The wire breaks are better

visible if the rope is lightly bended.

#

The internal examination of wire rope shall not be done in the regular maintenance, unless the

person is trained for that examination (ISO4309 Annex D).

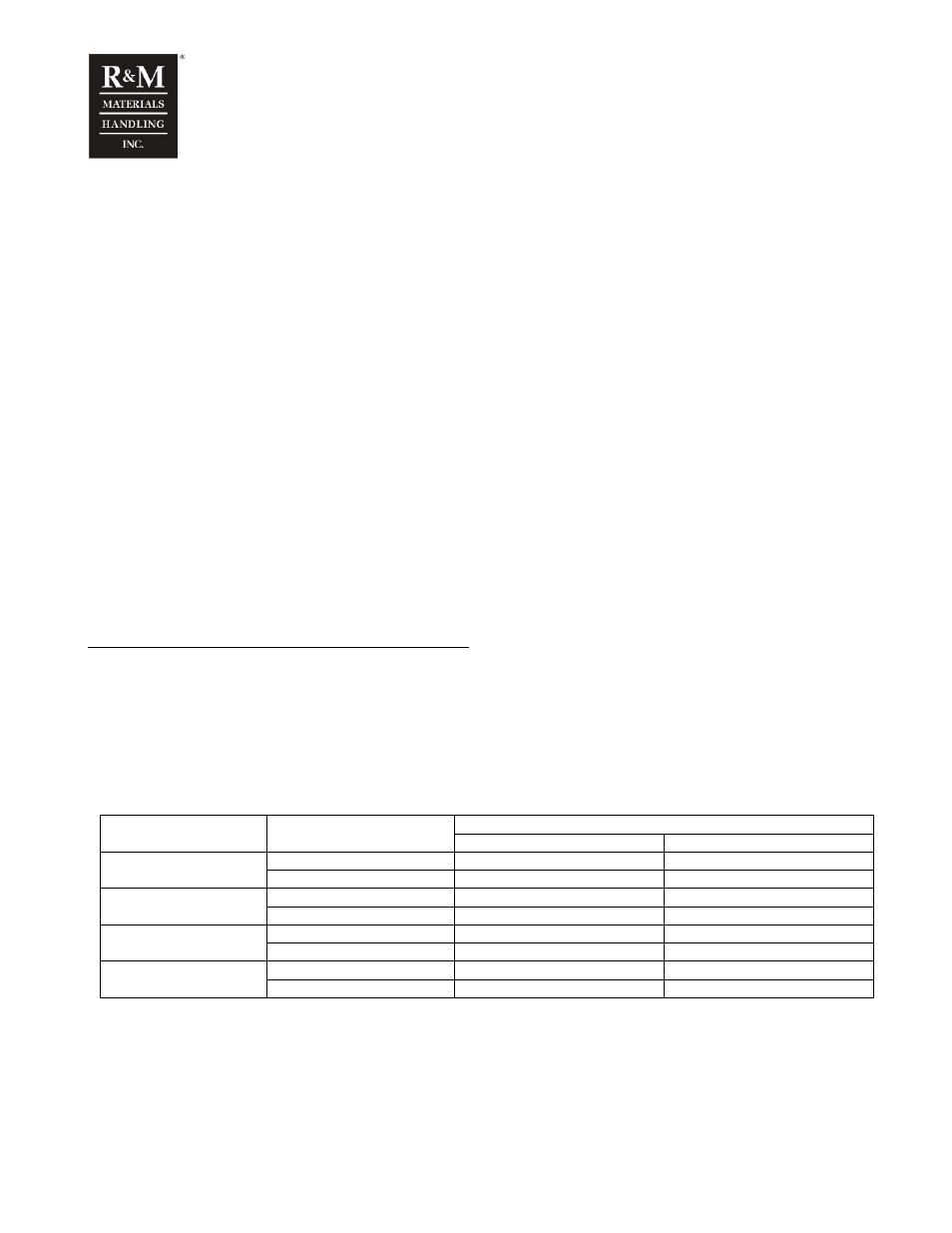

Standard Ropes and Heavy Duty Ropes

Maximum wire breaks

Rope diam.

mm

Detected length mm

Duty class M4

Duty class M5, M6

40 3

6

6.2 - 6.5

200 6

12

50 5 10

8

250 10

20

70 5 10

11

350 10

20

90 8 16

15

450 16

32