R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 25

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

25/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5.6 Trolley

buffers

The hoisting trolley is provided with rubber buffers. Some models are equipped with buffer extensions.

5.6.1 Service

• Check that the buffers and runway end stops are in good condition. Replace broken buffers.

• Check that the hoist buffers bump into the runway end stops or buffers of other trolley.

5.7 Hoisting

machinery

The main components of the hoisting machinery are the hoisting motor, gear and rope drum. Power from

the motor is transmitted via the rim gear of the transmission to the rope drum. One end of the

transmission train that is comprised of the hoisting motor, gearing and rope drum is fixed to the end

flanges of the hoisting machinery.

5.7.1 Service

• Check and replace the coupling between motor and gearbox. Note the exceptional service interval.

See the sections “Service” of the individual components for details.

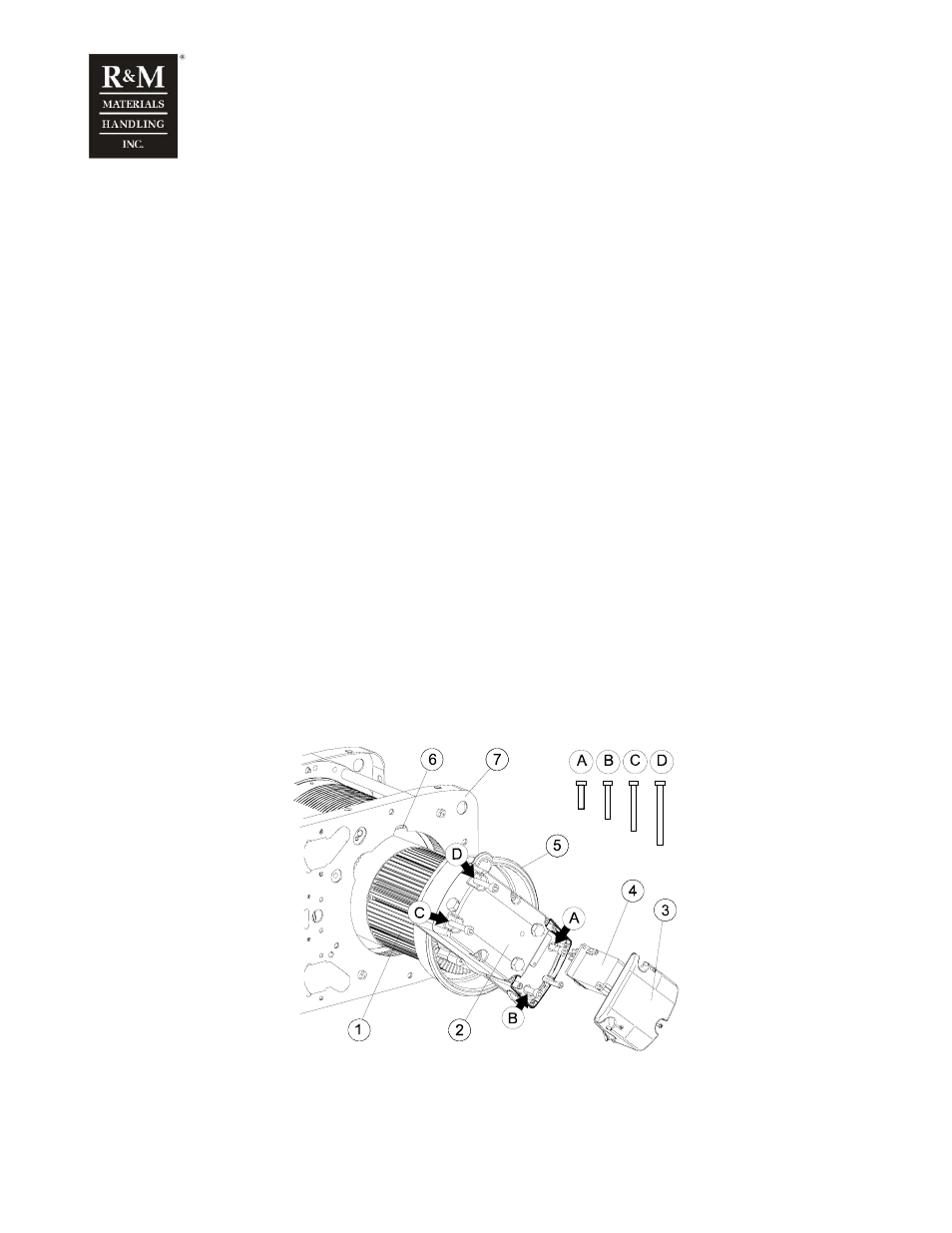

5.7.2 Assembly

Drum size ø 303/355/406 mm

The motor and gearbox are attached as a complete sub-assembly inside the rope drum. The motor-

gearbox subassembly must be extracted from the drum as a whole, in case any work on the gearbox,

motor or coupling is required.

c_r1hm1a1

1. Hoisting motor

2. Hoisting gearbox

3. Cover of connection box

4. Hoisting limit switch