R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 94

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

94/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Disassembly:

• Lower the hook onto a stable working-platform. Pull with a gloved hand some extra rope down from

the drum, so that the hook-block is free. If needed, adjust the lower limit switch.

• Switch OFF the power supply to the crane.

• Remove the shaft locking parts (5).

• Extract the shaft (5) from the support frame (3).

!

Be aware: the sheaves, as well as the sleeves will come loose one by one when extracting

the shaft.

Re-assembly:

• Insert the shaft (5) into the shaft support (3), while inserting the sheaves (4) and sleeves.

• Lock the shaft with the locking screws.

• Tighten all fixing screws to the required torque.

• Switch ON the power supply to the crane.

• Raise the hook block. Carefully guide the rope with a gloved hand until the hook block hangs free

from the working platform.

• If the lower limit switch has been adjusted, re-adjust to the correct position.

• Test the operation of the hoist.

5.30 Wire rope

The rope of the hoist is a wearing, load-bearing part. In order to ensure safe and efficient operation of the

hoist, it is essential to follow the safe working principles described in the safety instructions. Regular

inspection of the rope is a vital safety procedure requirement.

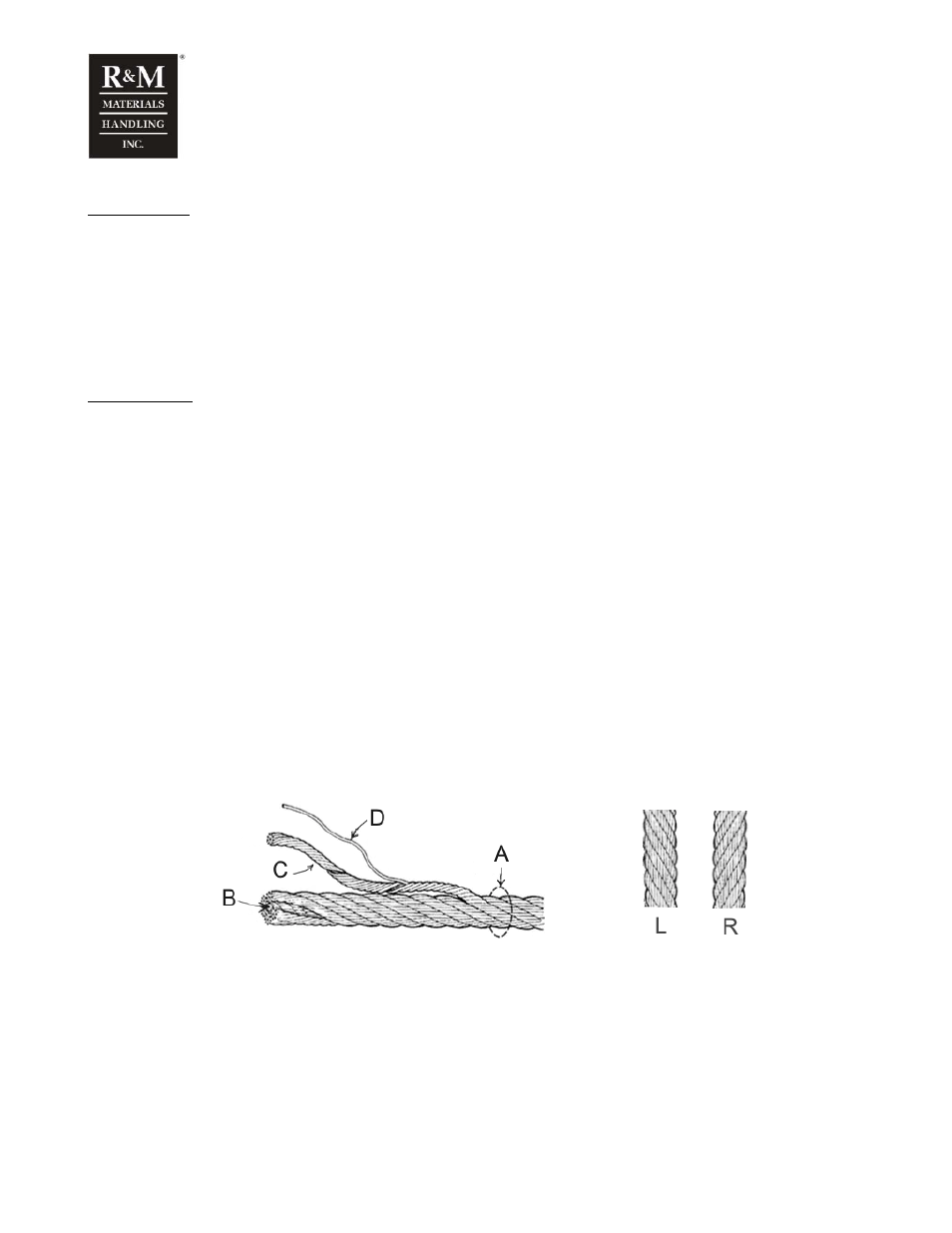

5.30.1 Wire rope structure

A. Rope

B. Rope core

C. Strand

D. Wire

L. Left hand lay

R Right hand lay

Standard and heavy duty wire ropes have 8 outer strands and steel core. The steel core is covered by

plastic in heavy duty rope. The lay of the outer strands is left handed in single rope hoists. True vertical

hoists have two ropes, one left hand lay, another right hand lay.