R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 41

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

41/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5.14.3 Adjustment

c_holi2b

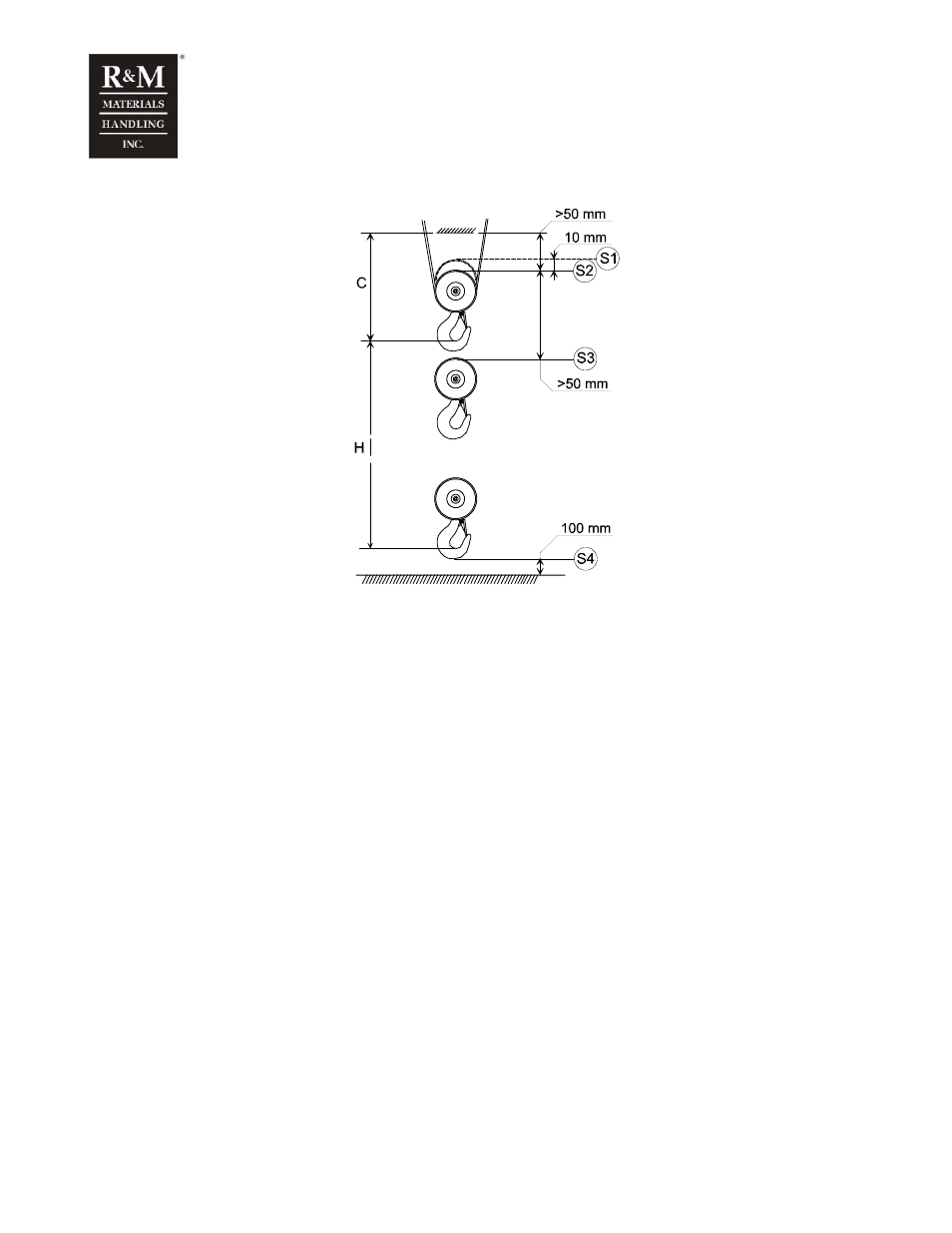

S1. Measurement for phase sequence supervision limit

S2. Measurement for upper limit of hoisting

S3. Measurement for slowdown limit of hoisting

S4. Measurement for lower limit of hoisting

C. Minimum distance of hook from bearing surface of hoist travel wheel

H. Maximum lifting height

• Lower the hook to approx. 100mm above the floor.

• Turn the screw “S4” until the limit switch “S4” is just activated.

• Test the operation. The downward motion must stop at the described distance.

• Raise the hook until the top of the hook-block is approx. 100mm under the bottom flange of the main

girder or other fixed structure.

• Turn the screw “S3” until the limit switch “S3” is just activated.

• Test the operation. The upward motion must slow down to Low speed at the described distance.

• Raise the hook until the top of the hook-block is approx. 50mm under the bottom flange of the main

girder or other fixed structure.

• Turn the screw “S2” until the limit switch “S2” is just activated.

• Test the operation. The upward motion must stop at the described distance.

• Raise the hook to the up most position, until the motion is stopped by the upper limit switch “S2”.