R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 89

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

89/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

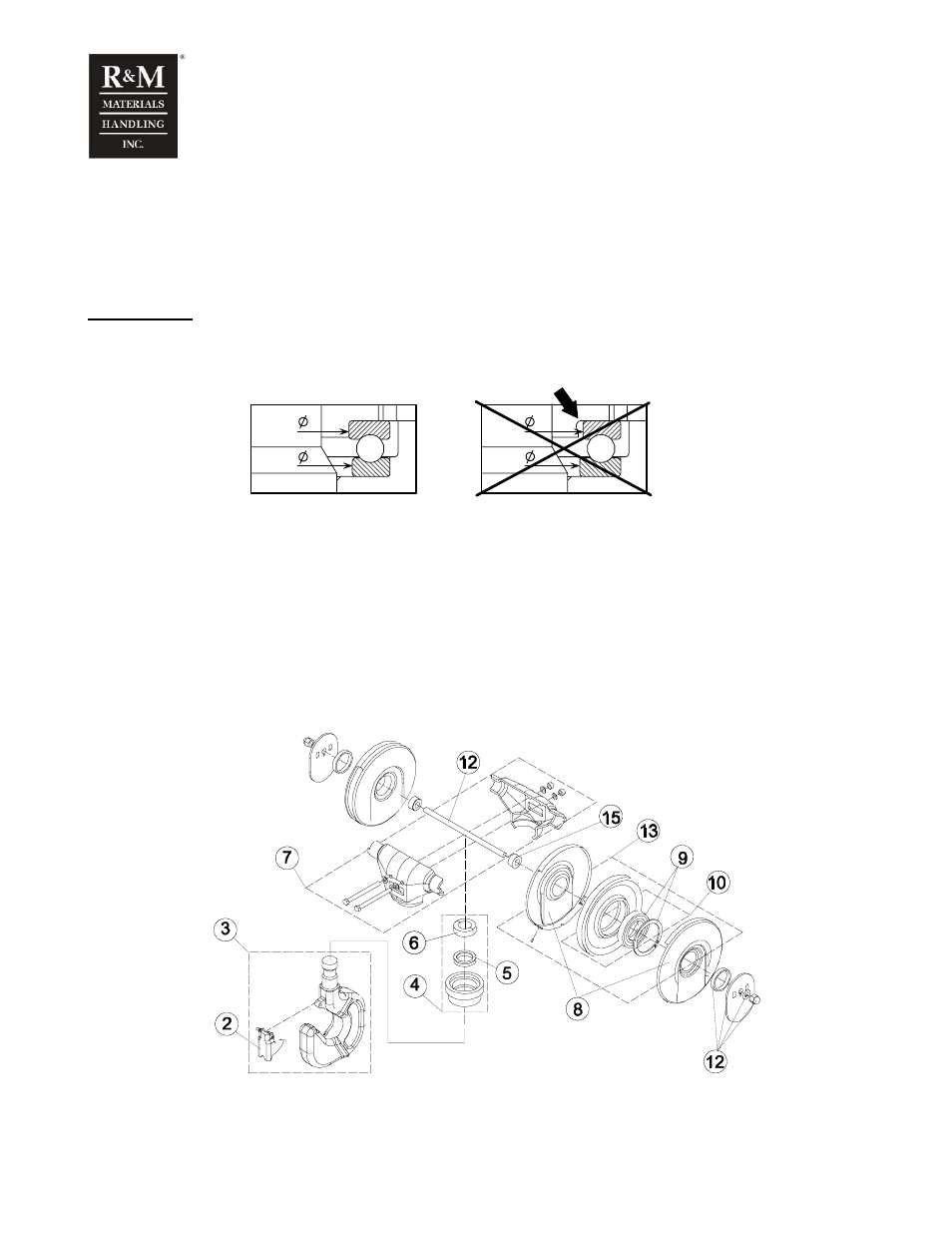

• Remove the hook-block fixing parts (13).

• Remove the side plates (11).

• Remove the sheave cover screws and remove the sheave cover plate (9).

• Remove the cover plate (7), locking set (8) and thrust bearing (5).

• Extract the hook (3) from the bearing set (4).

Re-assembly:

• Lubricate the thrust bearing and the hook shaft.

• Insert the hook (3) into the bearing house (4) and re-assemble the thrust bearing (5) and the locking

set (6).

1

2

1

2

c_hobeas1a

• Re-assemble the rope sheave (10), sheave cover plates (9) and the shaft (8).

• Insert the hook-assembly and the sheave-assembly into the side plates (11).

• Tighten the hook block fixing bolts and nuts (13) and the shaft assemble (8).

• Switch ON the power supply to the crane.

• Raise the hook block. Carefully guide the rope with a gloved hand until the hook block hangs free

from the working platform.

• If the lower limit switch has been adjusted, re-adjust to the correct position.

• Test the operation of the hoist.

Hook block 4-fall, 1-rope reeving, drum size

φ 303/355/406 mm

c_hb04as1b_005211

Note: The actual hook block outlook may vary slightly, depending on the manufacturing date!

2. Safety latch set

3. Hook forging.