3 safe operation – R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 8

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

8/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

3 Safe operation

3.1 Intended use of the hoist and ambient conditions

The hoist is intended for lifting and moving goods. The hoist may not be used for lifting and moving

people. The hoist is intended for indoor use or for use in outdoor premises when specially equipped for

the purpose. The ambient temperature should be -10 ... +40ºC (14…104ºF), with explosive proof hoists -

20 ... +40ºC (14…104ºF), or, if specially equipped, -20 ... +50ºC (-4…122ºF). The relative humidity of the

ambient should be less than 90%. If the hoist is used in exceptional ambient conditions (such as in a

windy area, a corrosive atmosphere or in an area prone to earthquakes) or is used to handle dangerous

materials (such as molten metal), any need for special equipment must be determined with the

manufacturer or the manufacturer's representative.

3.2 Sound intensity level

The sound intensity level of the hoist in an operating location will not exceed 70dB (A).

3.3 Service

classification of hoist

Safe and effective operation of the hoist is dependent on correct classification of the hoist's operating

group. According to FEM9.511 standard the hoist's operating group can be determined from its:

- load

spectrum

-

average daily operating time

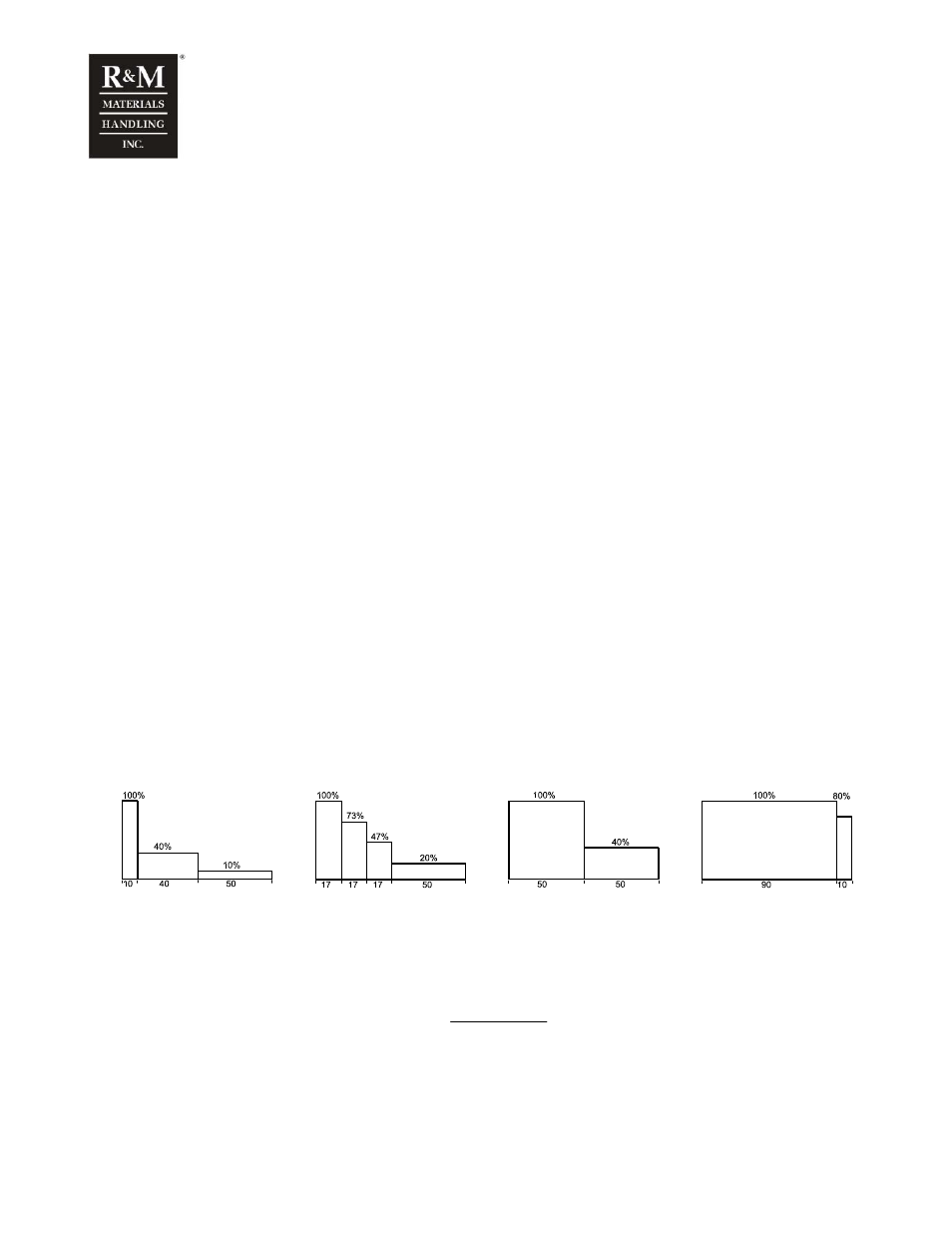

3.3.1 Load spectrum

The load spectrum can be determined from the table below.

LIGHT

Occasional full load.

Usually light load.

Small fixed load.

MEDIUM

Occasional full load.

Usually light load.

Average fixed load.

HEAVY

Repetitive full load.

Usually average load.

Heavy fixed load.

VERY HEAVY

Usually almost full load.

Very heavy fixed load.

Load %

Operating time %

Load %

Operating time %

Load %

Operating time %

Load %

Operating time %

3.3.2 Average daily operating time

The average daily operating time of the hoist can be calculated from the running time of the hoisting

machinery [hours/day].

60

2

∗

∗

∗

∗

=

V

T

N

H

t

H = average hoisting height [m]

N = number of work cycles per hour [cycles/h]

T = daily working time [h]

V = hoisting speed [m/min]