R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 116

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

116/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

6.6.2.1 Standard reeving (1 rope from drum)

Falling

ropes

L1 L2

(mm.)

Inch

(mm.)

Inch

2 0

0

97

3,82

4 18

0,71

146

5,75

6 40

1,57

146

5,75

6.6.2.2 Standard reeving (2 ropes from drum)

Falling

ropes

L1 L2

(mm.)

Inch

(mm.)

Inch

2 21

0,82

97

3,82

4 0

0

146

5,75

6 6

0,23

146

5,75

8 12

0,47

146

5,75

6.6.3 Outfitting the hoist

• Install the power supply. Refer to the section “Connecting the to mains network”.

• Adjust the limit switch for hoisting. Refer to the section “Adjusting hoisting limit switch”.

• Carry out the commissioning inspection and complete the commissioning log. Refer to the section

“Commissioning”.

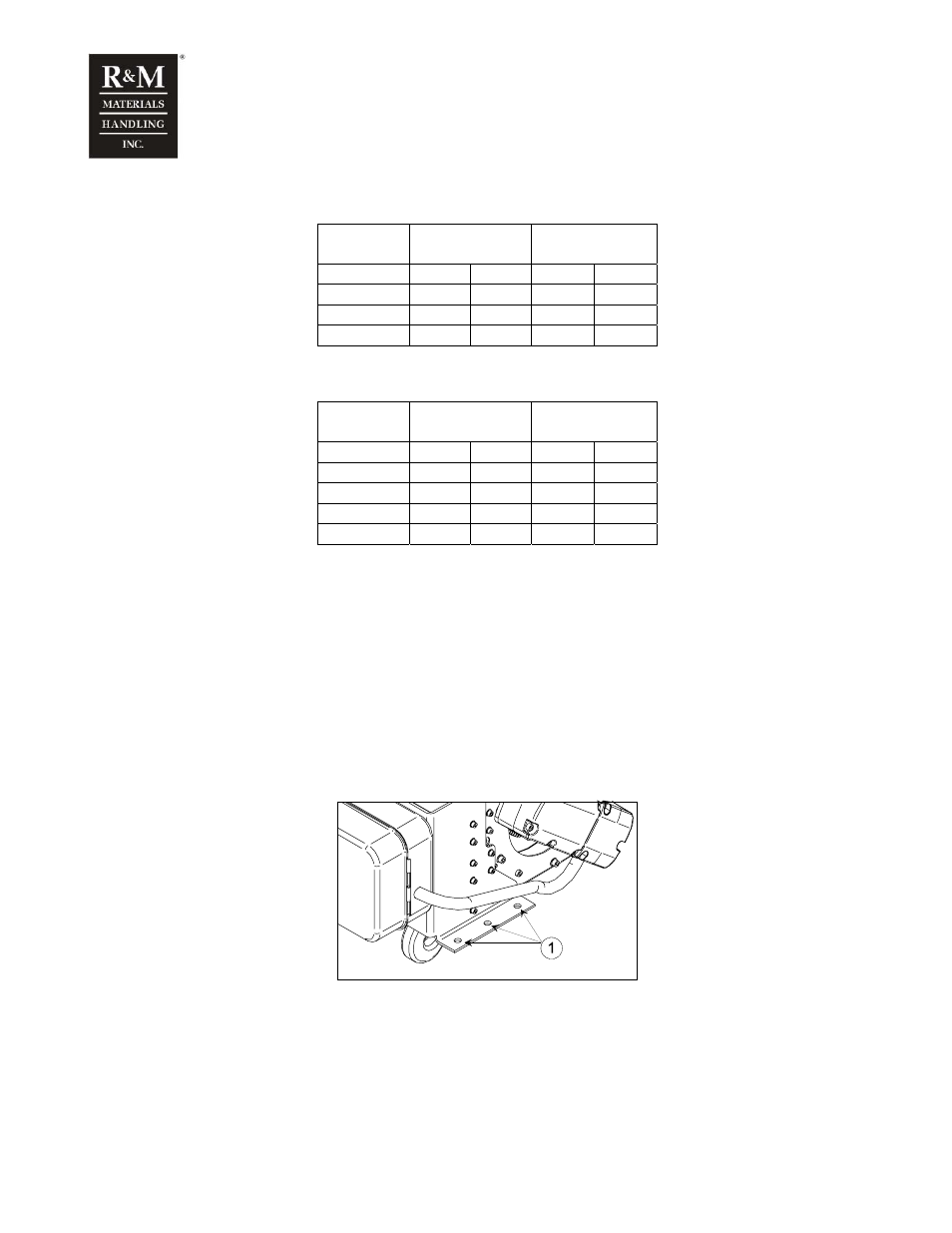

6.7 Installing the hoist, fixed trolley

c_fab1a

• Remove the temporary transport supports. Take the hoist out of the packing and move it to the

installation site.

• Check that the fixing holes in the site of location match the fixing holes (1) in the trolley.

• Lift the trolley into position. Fasten the fixing screws.